Fin-pipe shaped radiator specially adapted to a semiconductor chilling unit and the method of making same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

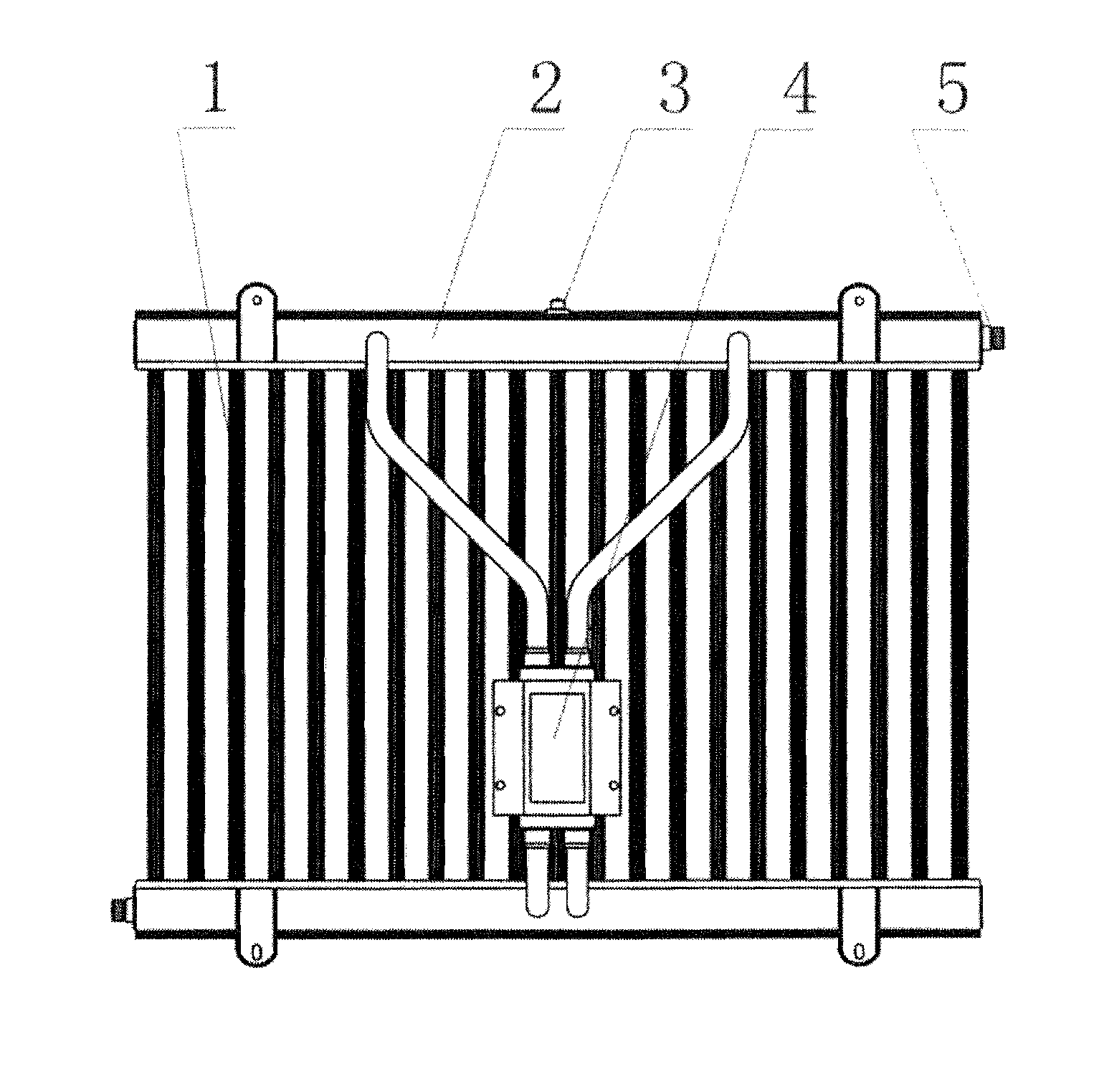

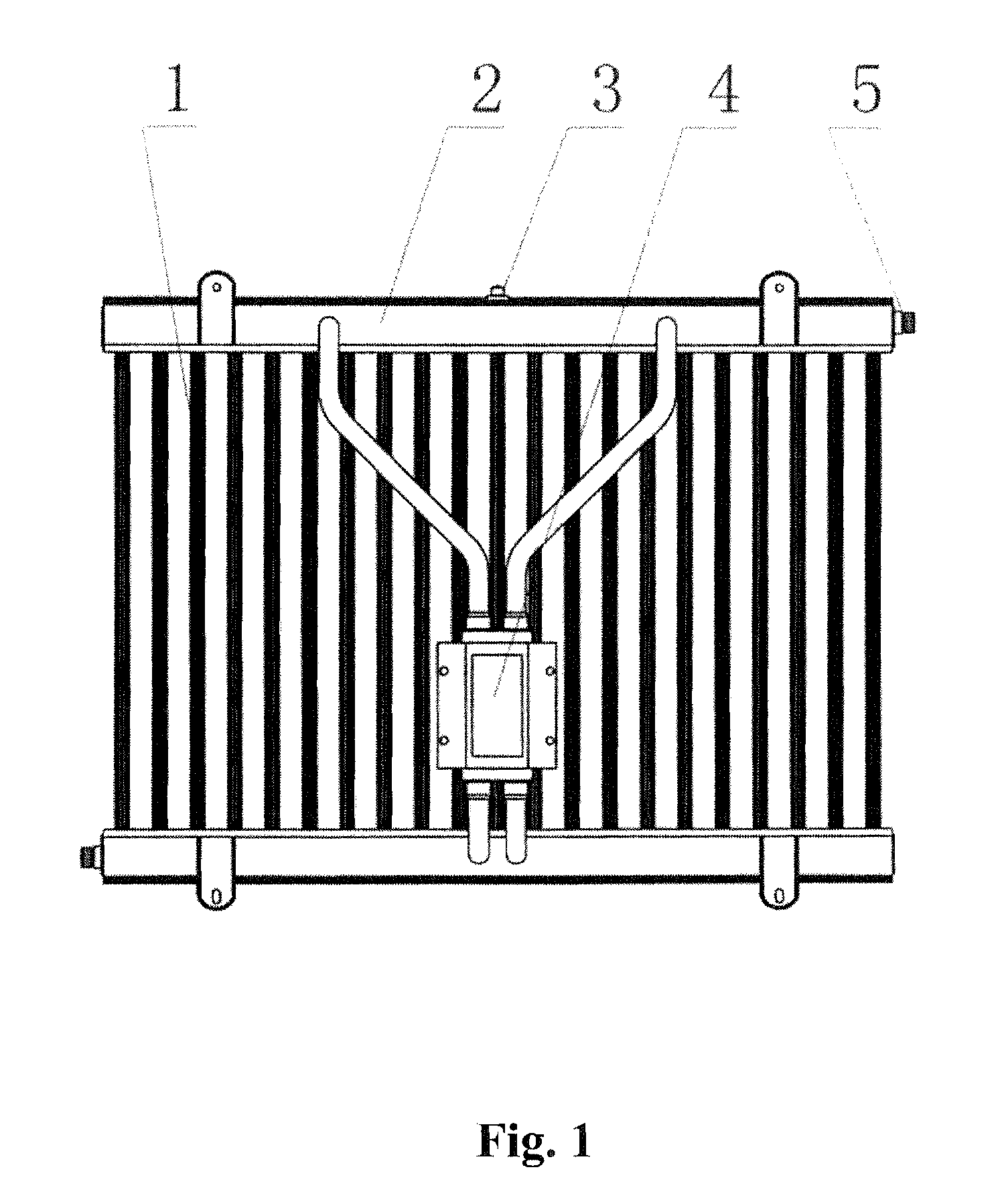

[0039]This invention intends to introduce a fin-pipe shaped radiator specially applied to semiconductor chilling unit with favorable heat radiating effect and simplified structure which is suitable for standardized production.

[0040]The other is to introduce a fin-pipe shaped radiator specially applied to semiconductor chilling unit with favorable heat radiating effect which is suitable for industrialized production.

[0041]The technical solution for this invention is generally as follows:

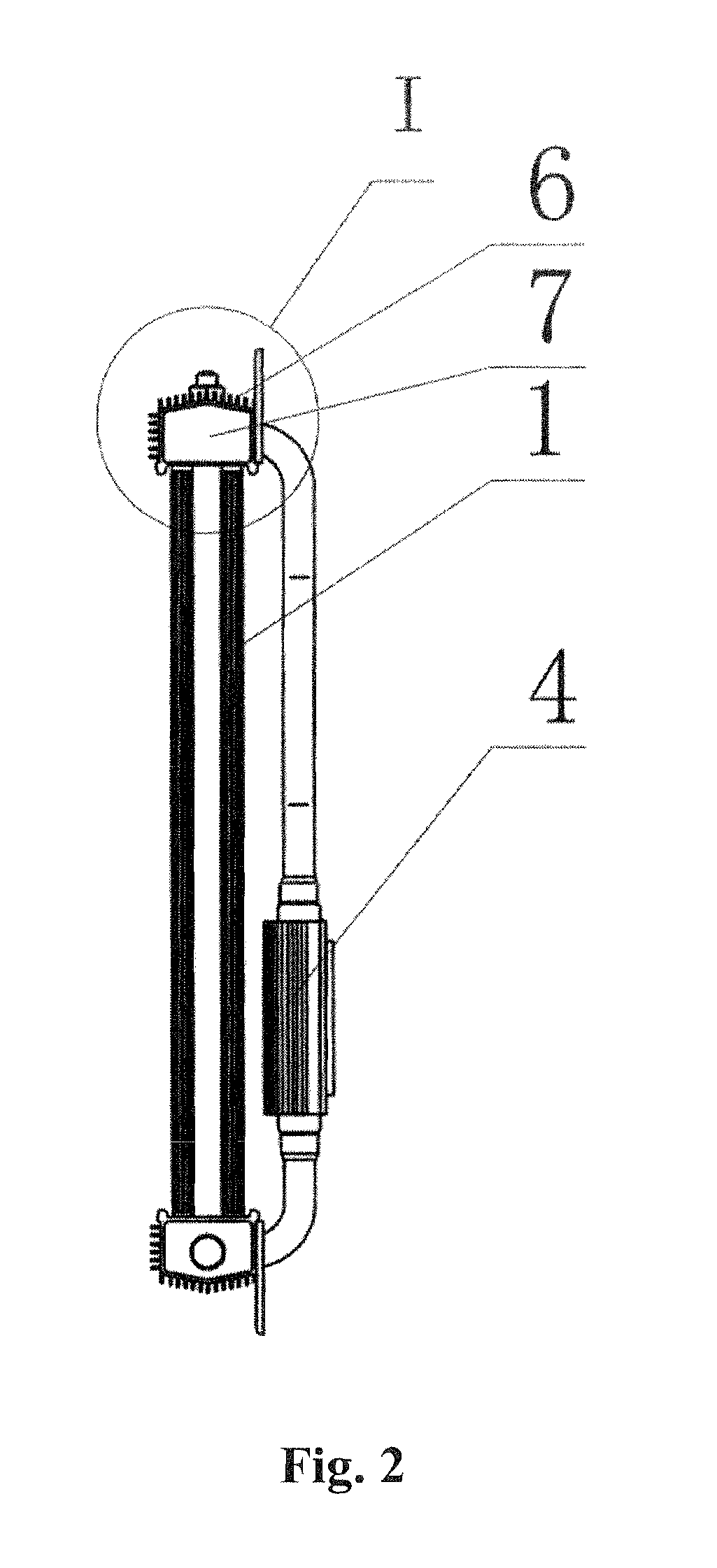

[0042]A. Separately manufacture shaped vertical pipe (1), horizontal pipe and arched plate (2) by extruding technique, and manufacture end caps (7) (with groove welded around) and cover panel (9) (with hole flanging on the surface and grooves at both sides) by extruding technique with plate material coated with welding dressing; or machine through-hole directly on the surface of the horizontal pipe;

[0043]B. Cut arched plate (2) and vertical pipe (1) into corresponded length;

[0044]C. Assemble arched pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com