Lubricating composition

a technology of lubricating composition and additive, which is applied in the direction of additives, lubricant compositions, petroleum industry, etc., can solve the problems of unsatisfactory lead corrosion, metal corrosion, present in the engine, etc., and achieve the effect of improving the lead corrosion protection of the lubricant composition and improving the lead corrosion protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0062]The following examples are illustrative of the invention and its advantageous properties. In these examples as well as elsewhere in this application, all parts and percentages are by weight unless otherwise indicated. It is intended that these examples are being presented for the purpose of illustration only and are not intended to limit the scope of the invention disclosed herein.

examples 1 to 7

[0063]The following examples of Table I illustrate a synergism between the triazoles and amides of the present disclosure. Each formulation of Examples 1 to 7 of Table I were tested in the Ethyl Oxidation Test, a bubbling oxidation test run for 120 hours on 300 grams of oil in an ASTM D943 apparatus at 300° F., with 5 l / hr oxygen bubbling through the oil, and metal coupon catalysts, one inch square each of copper, iron and lead present.

[0064]As the test proceeds, the oxidized oil becomes very corrosive to the lead coupon as shown by Example 5 below. The lead content of the oxidized oils was done by the ICP method.

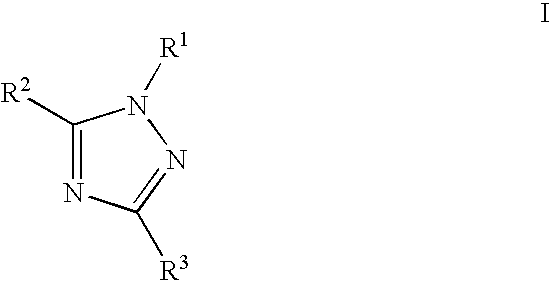

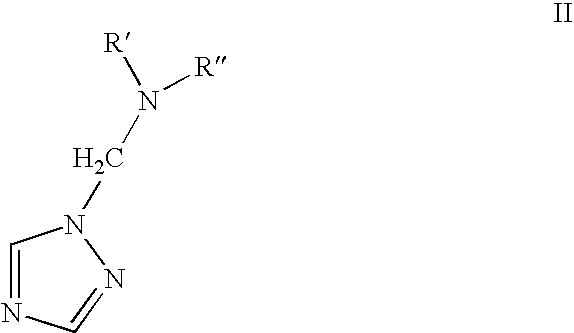

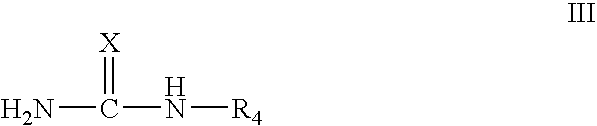

[0065]The formulations in the examples below consisted of a “core” group of medium speed diesel additive components including antiwear / EP agents, alkalinity agents, detergents and antioxidants. A 1,2,4-triazole compound of formula II, (Irgamet 30) and an amide of the present disclosure (a reaction product of aminoguanidine bicarbonate and oleic acid) were added to this “cor...

examples 8 to 12

[0068]The Examples of Table 2 below were prepared similar to those of Table I above, but with the ingredient compositions specified in Table 2. All of the blends of Examples 8 to 12 were prepared using the same core package, which included typical medium speed diesel combinations of detergents, dispersants, antioxidants, alkalinity components and antiwear agents. The same amount and type of dispersant was used in all of Examples 8 to 12. These Examples were also subject to the Ethyl Oxidation Test, which was carried out as described above for Examples 1 to 7. The results of Examples 8 to 12 are indicated in Table 2 below.

TABLE 2Ethyl Oxidation Testing Of MSD FormulationsEXAMPLE89101112“Core” MSD12.85% 12.85% 12.85% 12.85% 12.85%FormulationBase Oil87.15%89.985%85.664%85.710%85.677%Triazole0165014,860 0330(ppmw)Amide000 1.44% 1.44%EOT 120989020201090339184HoursLead (ppmw)Mgs Pb Lost @288655629894 51120 Hoursfrom LeadCoupons

[0069]The results of the tests shown in Table 2 corroborate th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com