Thermoelectric power generation device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

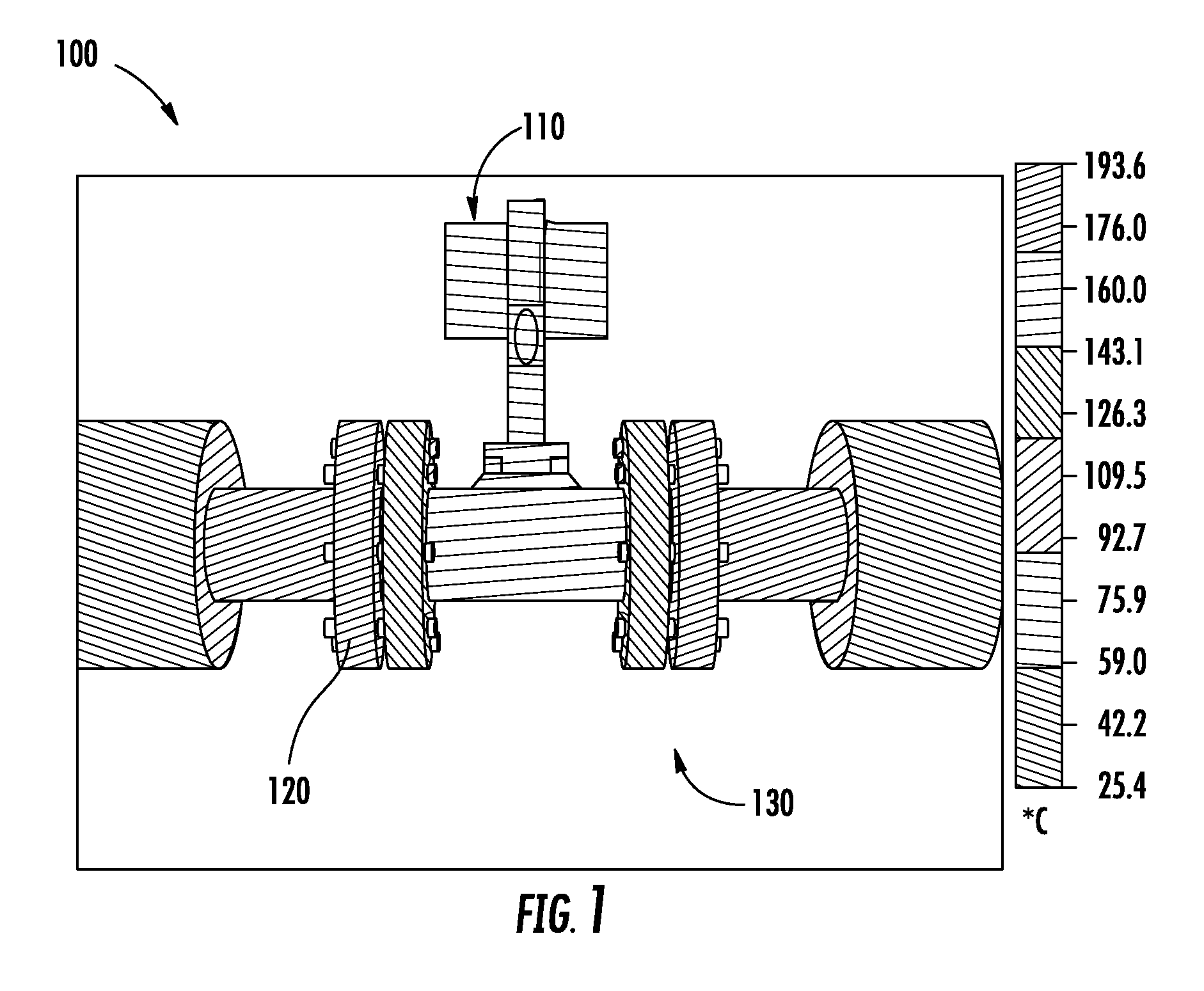

[0096]An example embodiment of the invention is described below. The example embodiment consists of a thermoelectric power generation system including a pair of assemblies. The two assemblies were identical except for the material and thickness used for the fins (specifically, 0.02 inch thick aluminum and 0.03 inch thick copper). Example parameter values assumed in the theoretical analysis are listed in the table in FIG. 9A. The table in FIG. 9B shows important derived quantities used in the thermal analysis. In this specific example, the thermoelectric module used was a Melcor Model HT4-12-40, constructed by Melcor Incorporated, of 1040 Spruce Street, Trenton, N.J. 08648.

[0097]The test bed used for testing the example thermoelectric power generation systems had a temperature of approximately 125° F. at an elevation of 6 feet above the floor in the summer and 115° F. in the winter. Preliminary data suggested that the test bed has a higher than average room temperature. The vortex st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com