Chrome plated articles of variable surface appearance

a technology of surface appearance and chrome plating, applied in the field of chrome plating, can solve the problems of accelerated corrosion, concentrated and concentrated corrosion of coated parts, and high cost, and achieve the effect of retaining corrosion resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

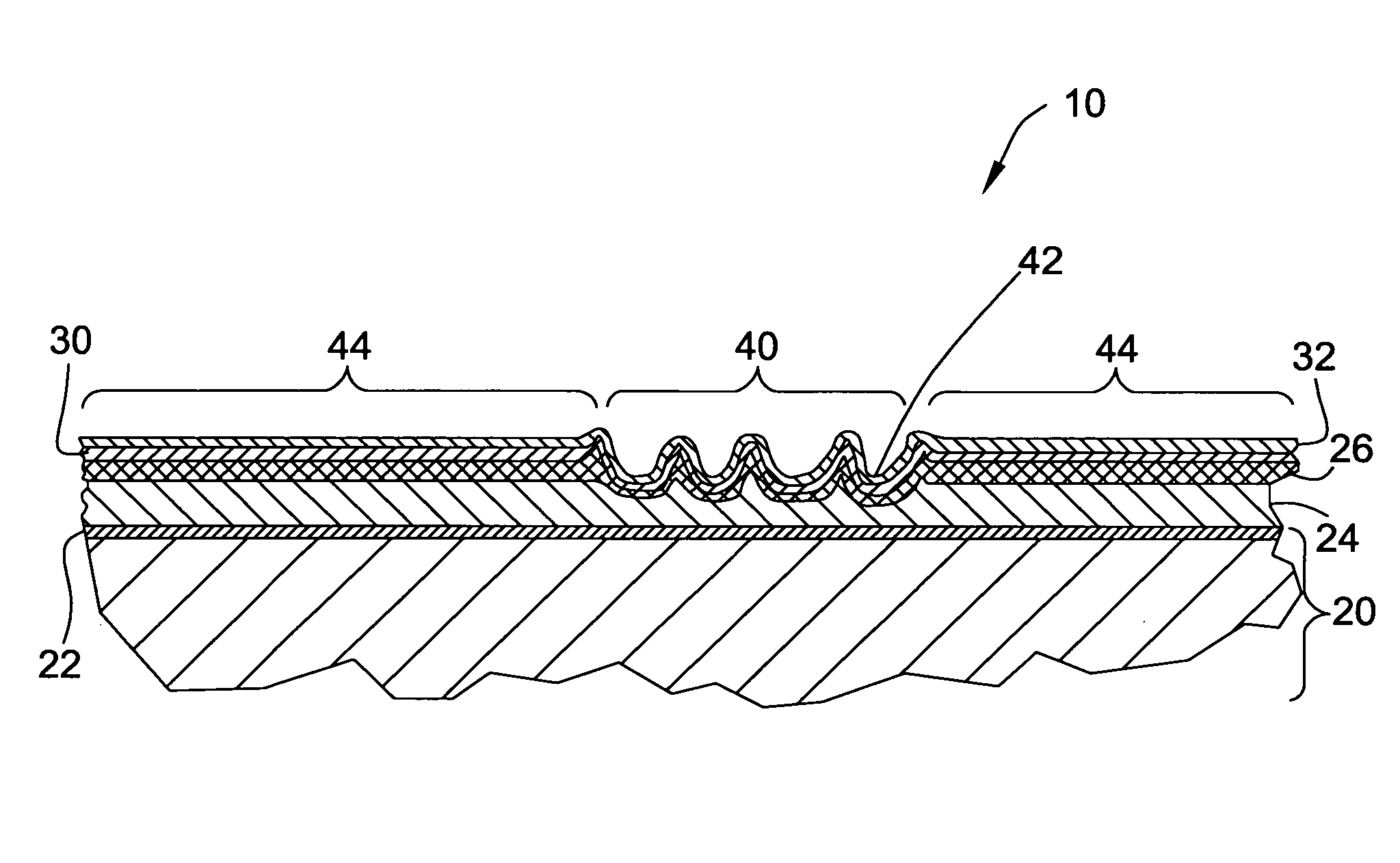

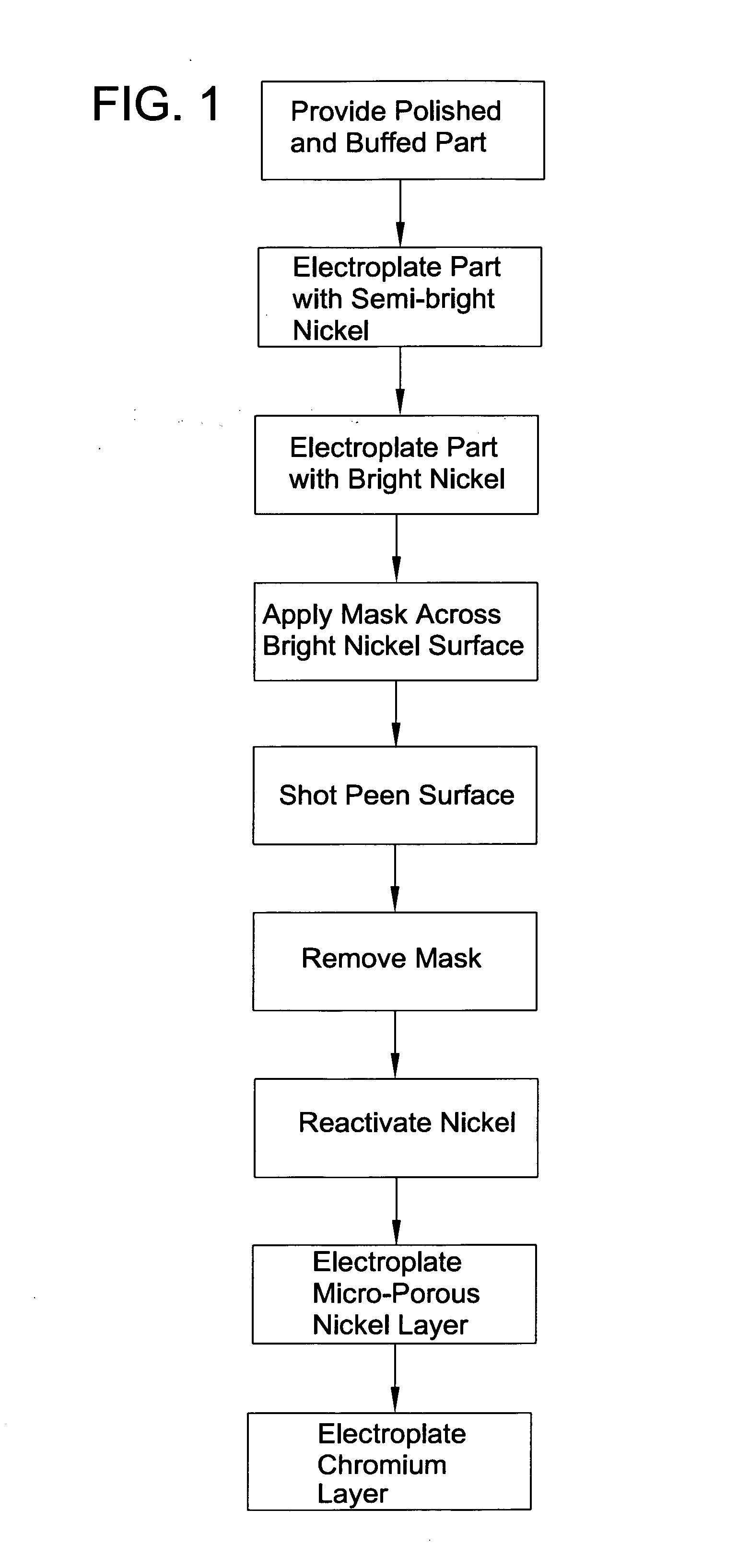

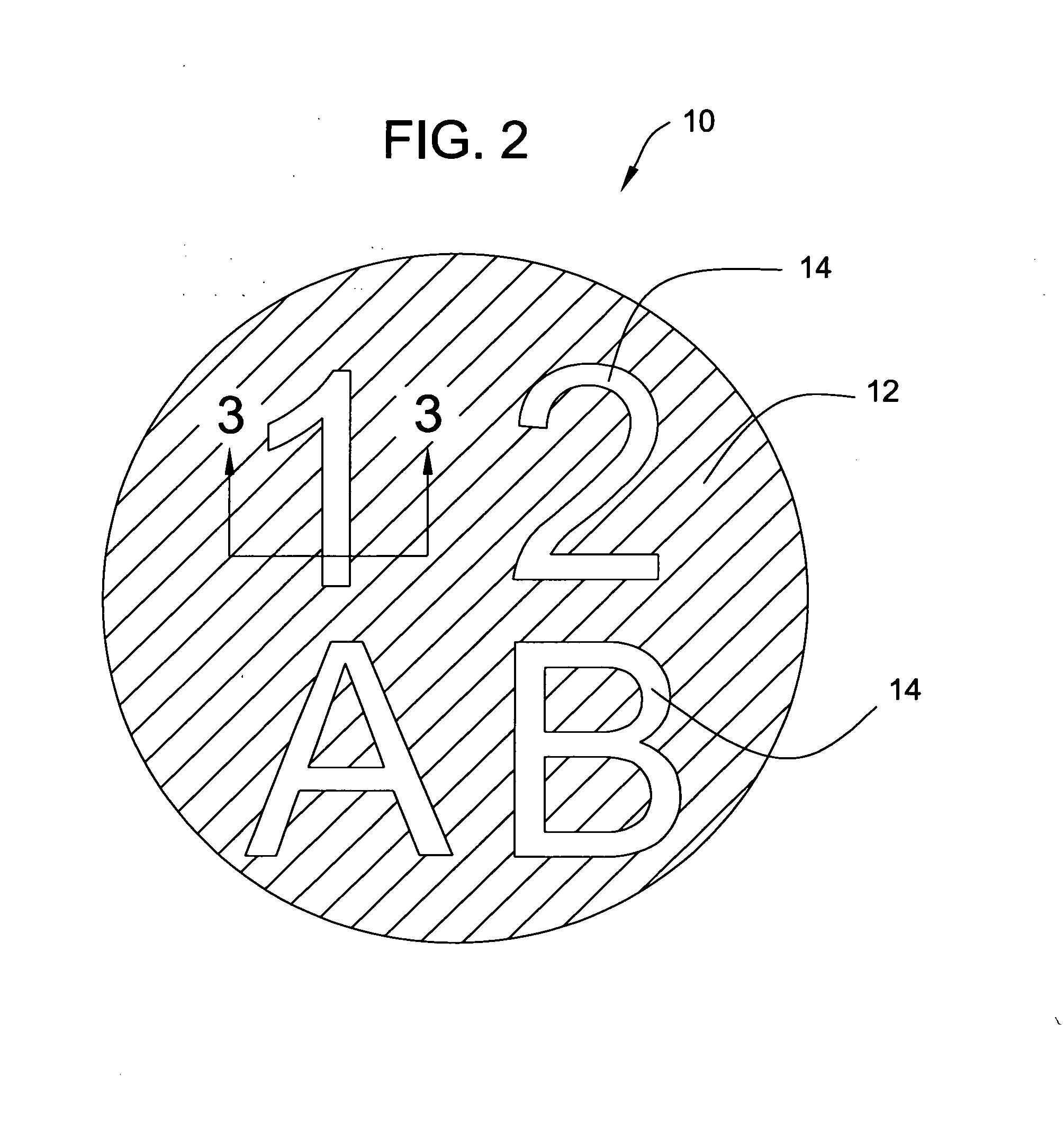

[0017]Reference will now be made to the drawings wherein, to the extent possible, like reference numerals are utilized to designate corresponding components throughout the various views. FIG. 1 is a flow diagram setting forth exemplary steps in a process for introducing aesthetic or communicative designs of variable reflectivity across the surface of a chrome-plated article while maintaining substantial corrosion resistance. By way of example only, and not limitation, FIG. 2 illustrates an exemplary chrome plated article 10 produced by the process of FIG. 1. As shown, the exemplary chrome plated article 10 includes an exterior show surface 12, wherein visible designs 14 in the form of alphanumeric characters have been developed across the surface 12. Of course, the process may also be utilized to impart aesthetic designs if desired. The designs 14 are visually perceptible across the exterior show surface 12 of a finished article due to variable light reflectance characteristics of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| air pressure | aaaaa | aaaaa |

| corrosion resistance | aaaaa | aaaaa |

| acid- | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com