Pliable plastic film and container using the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 2 to 8

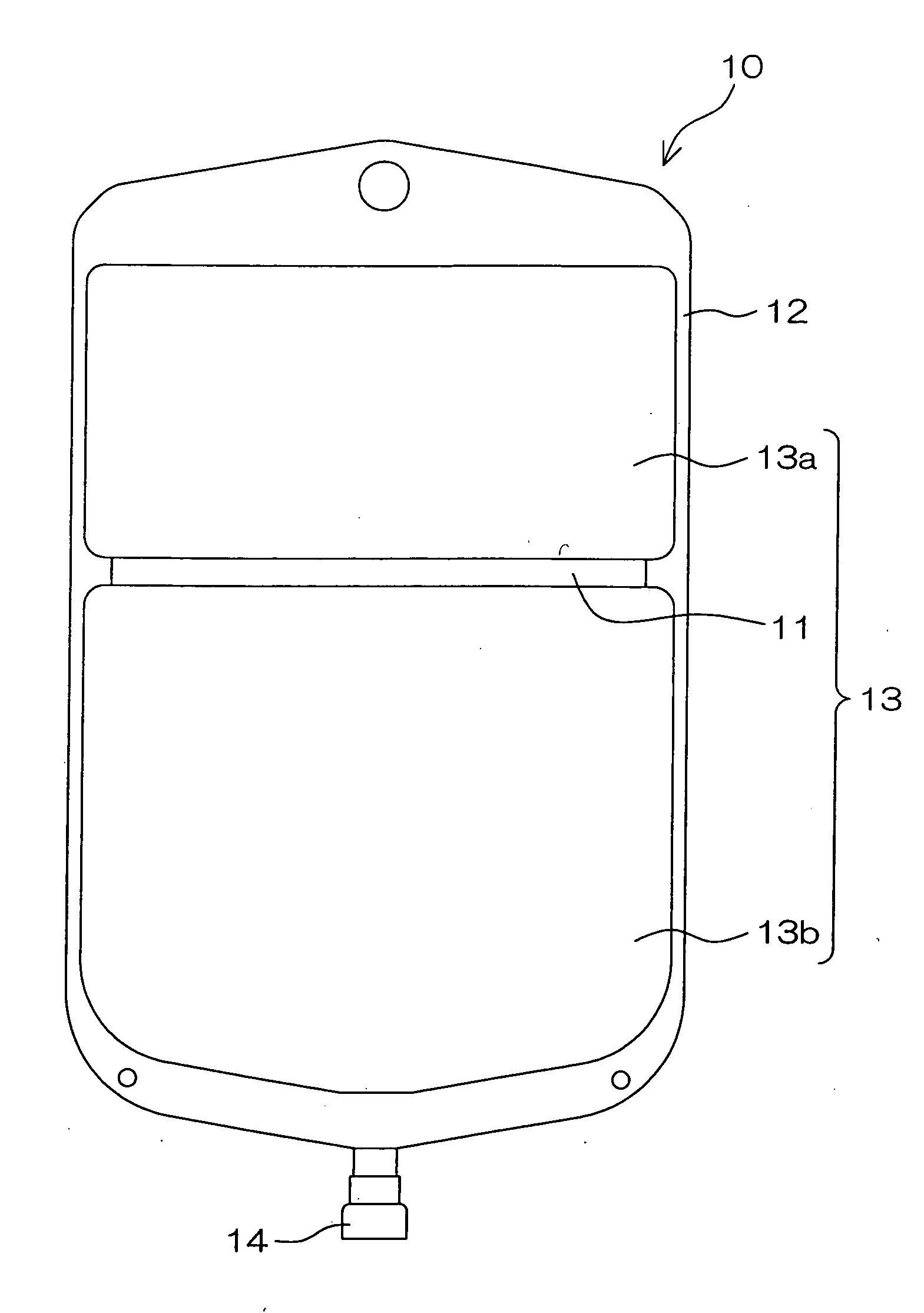

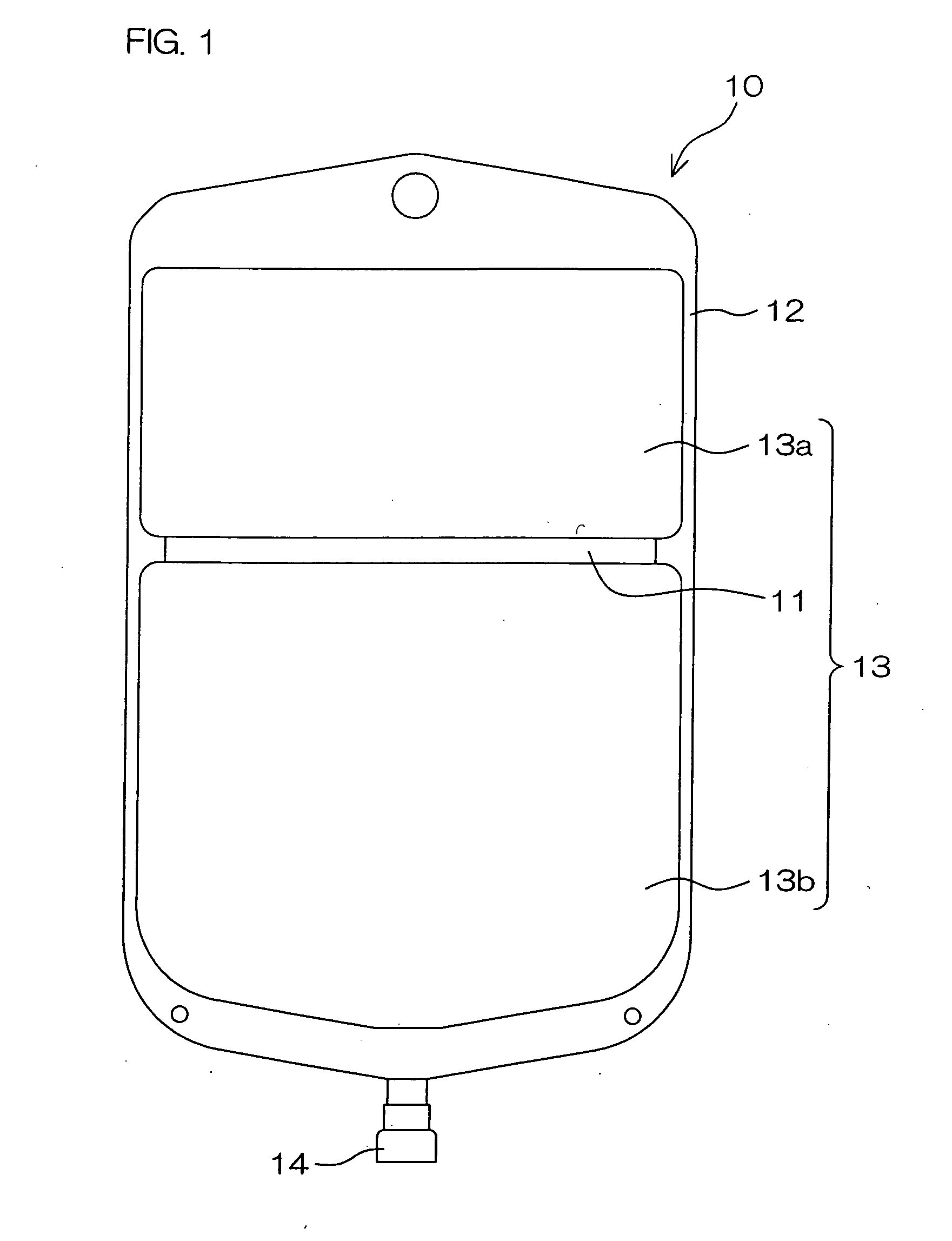

[0116]In the same manner as in Example 1, except for employing the layer configuration shown in Table 3 below, a pliable plastic film was produced and also a container (infusion solution bag) 10 shown in FIG. 1 was produced using the film in the same manner as in Example 1.

TABLE 3Upper columns: Kinds of plastics constituting layersLower columns: Mixing ratios (weight ratios) of plasticsFirstRein-SecondSealingflexibleforcingflexibleOutermostlayerlayerlayerlayerlayer(30 μm)(90 μm)(20 μm)(90 μm)(20 μm)Example 2PP1 + PP2PP1 + PEEPP1PP1 + PEEPP1(95:5) (60:40)(60:40)Example 3PP1 + PP2PP1 + PEEPP1PP1 + PEEPP1(90:10)(60:40)(60:40)Example 4PP1 + PP2PP1 + PEEPP1PP1 + PEEPP1(80:20)(60:40)(60:40)Example 5PP1 + PP2PP1 + PEEPP1PP1 + PEEPP1(70:30)(60:40)(60:40)Example 6PP1 + PP2PP1 + PEEPP2PP1 + PEEPP1(85:15)(60:40)(60:40)Example 7PP1 + PP2PP1 + PEECOPPP1 + PEEPP1(85:15)(60:40)(60:40)Example 8PP1 + PP4PP1 + PEEPP1PP1 + PEEPP1 + PP2(85:15)(60:40)(60:40)(50:50)

[0117]With respect to the containers (i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com