Molded mascara brush with oval core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

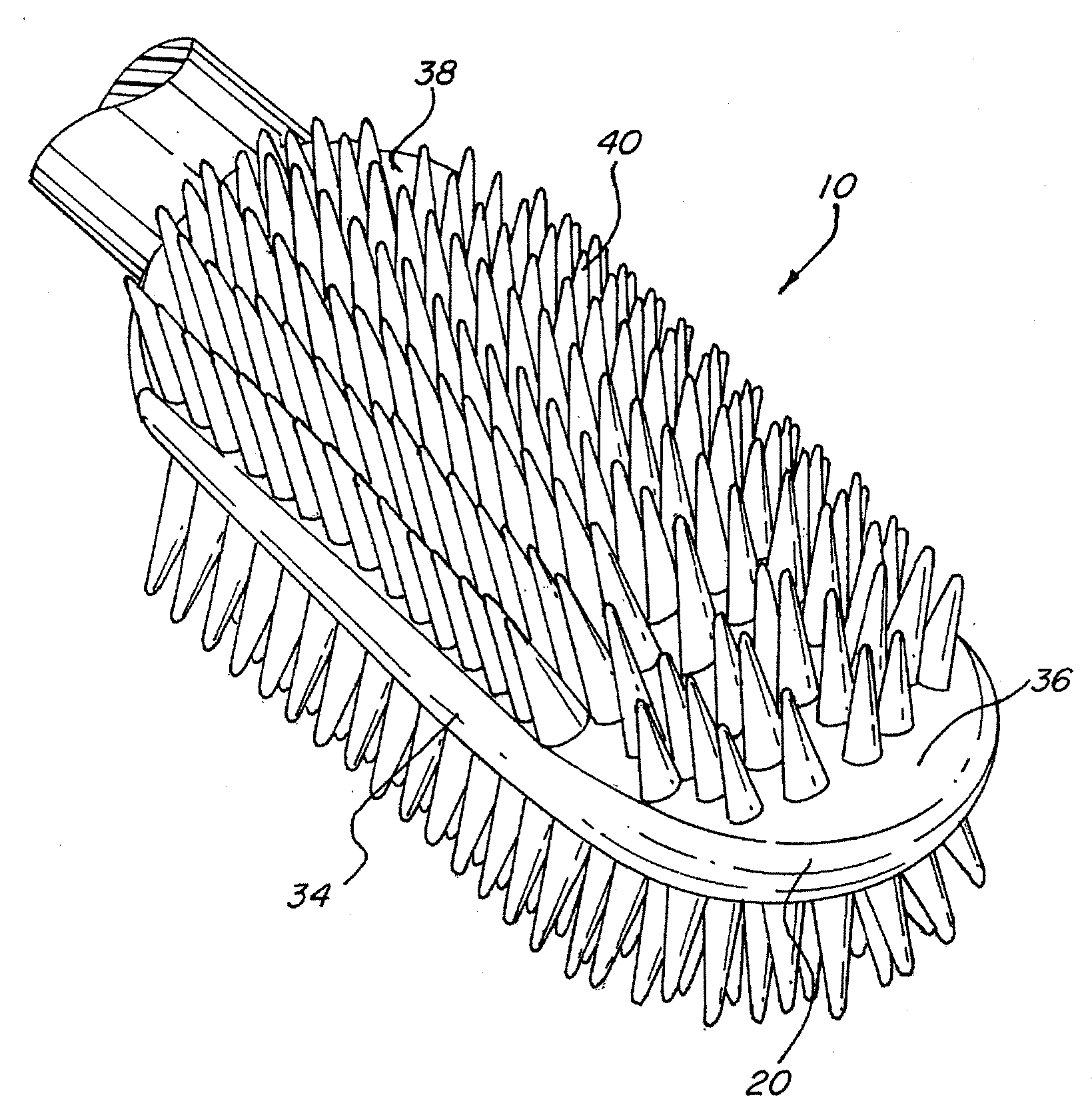

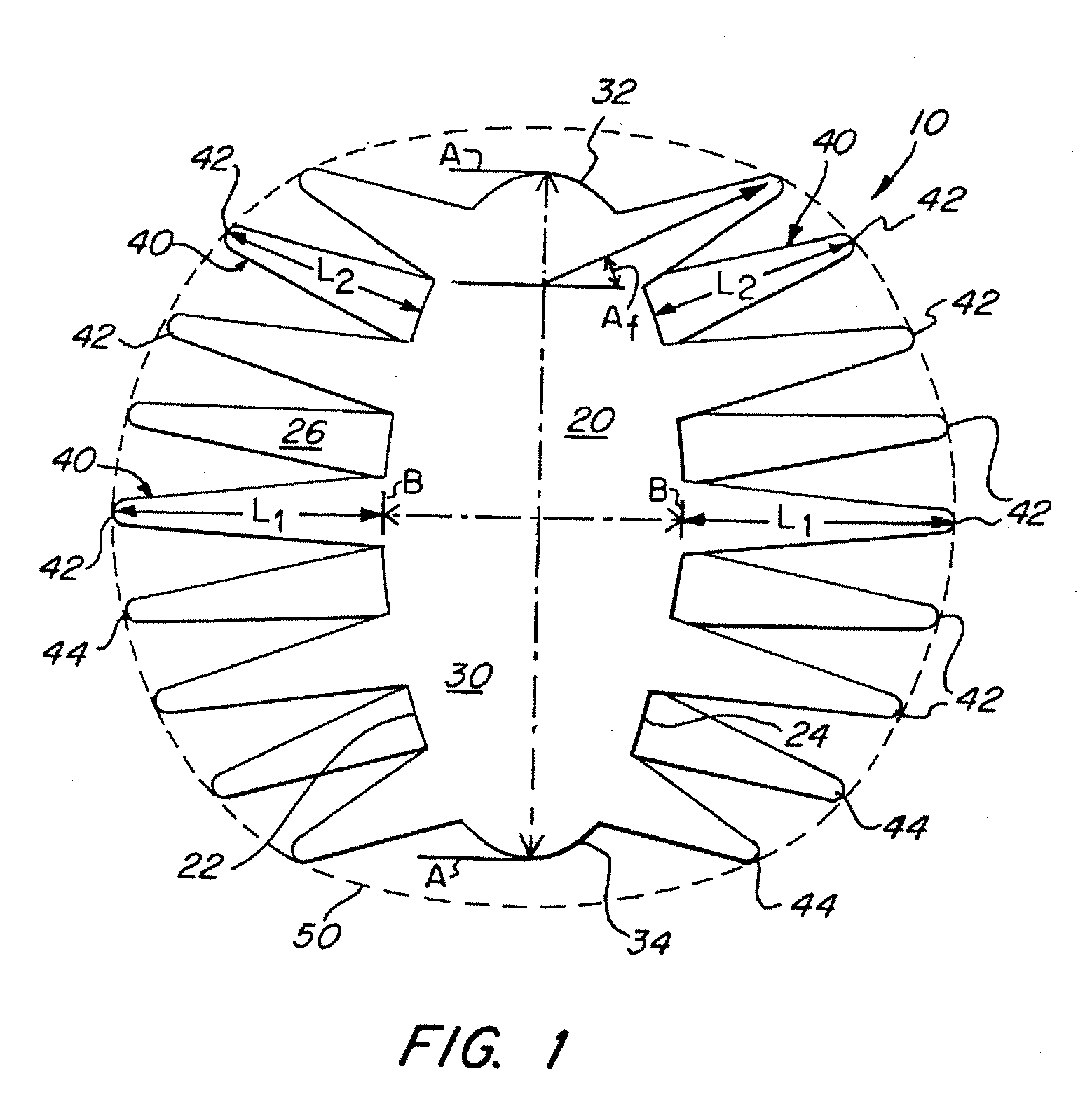

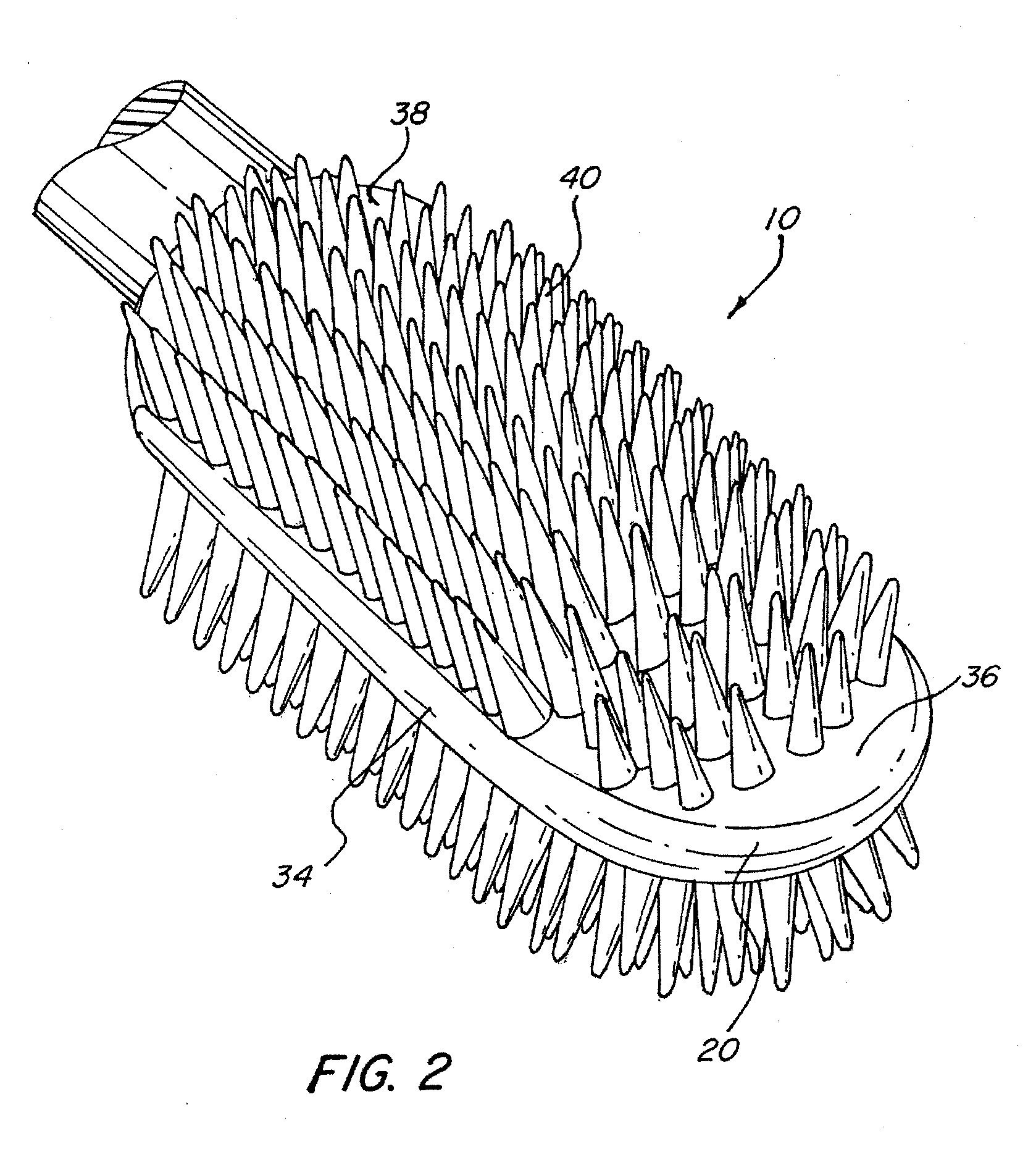

[0019]Referring now to FIGS. 1-4 and 7, a molded brush assembly 10 is shown. Molded brush assembly 10 comprises a core 20 of oval cross-section having a major axis A-A and a minor axis B-B. As used herein, the term “oval cross-section” includes all convex closed curves, and specifically includes elliptical cross-sections, rounded rectangle (i.e., racetrack) cross-sections, lens shaped or lenticular cross-sections. “Oval cross-section” also includes Cassini ovals, and other convex curves, such as semicircles or curved ends connected by curved lines or by intersecting straight lines. “Oval cross-section” expressly excludes circular cross-sectional shapes. Preferably, the oval cross-section is symmetrical across both the major axis A-A and the minor axis B-B, e.g. the oval cross-section has two axes of symmetry.

[0020]The oval cross-sectional core of the brush of the present invention provides an advantage over circular core molded brushes in that the oval core permits the brush to be f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com