Basement wall and floor system

a technology of floor system and foundation wall, which is applied in the direction of walls, cellars, building repairs, etc., can solve the problems of low thermal insulation properties, damp and clammy basements with concrete walls, and high construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

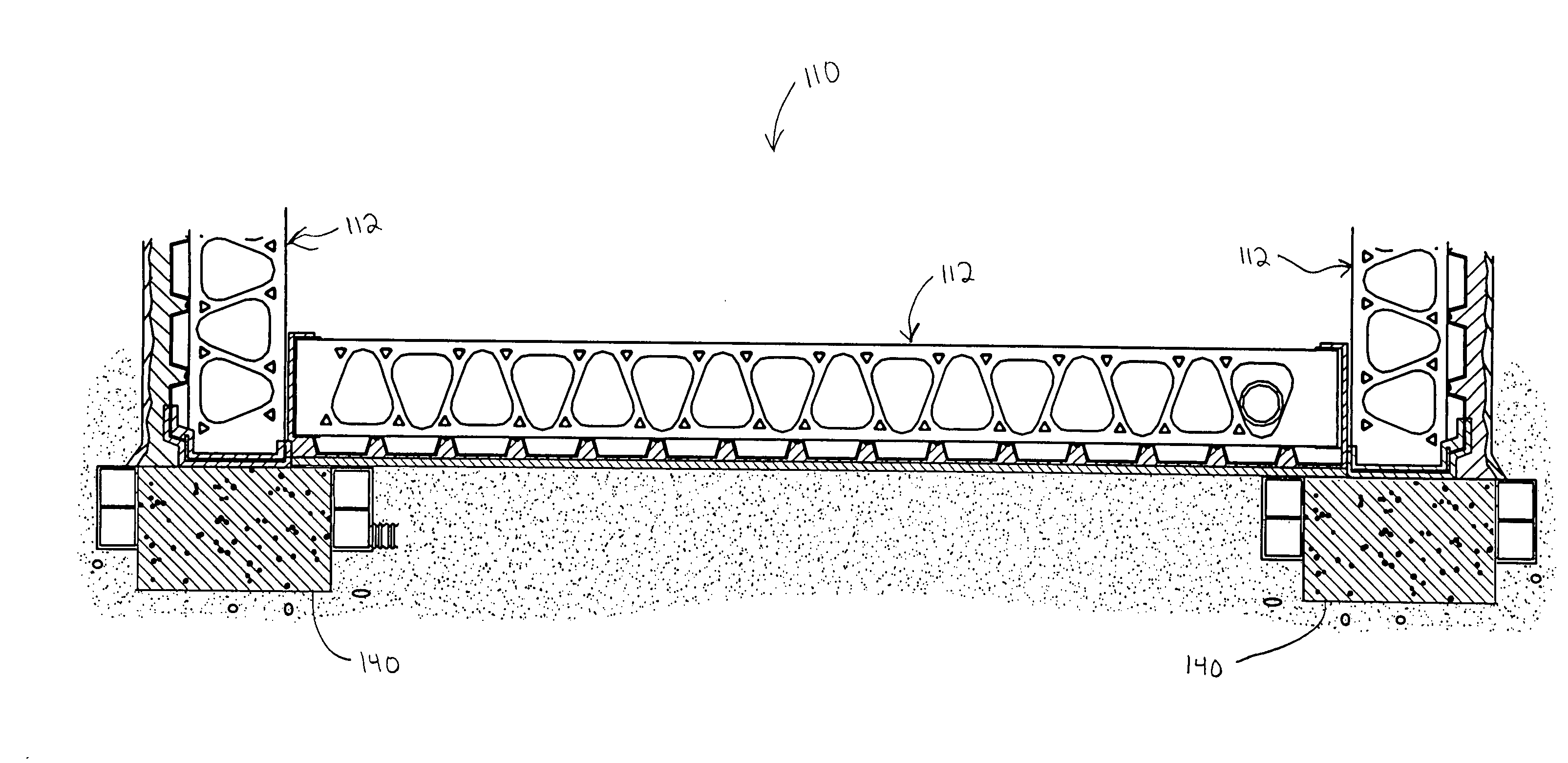

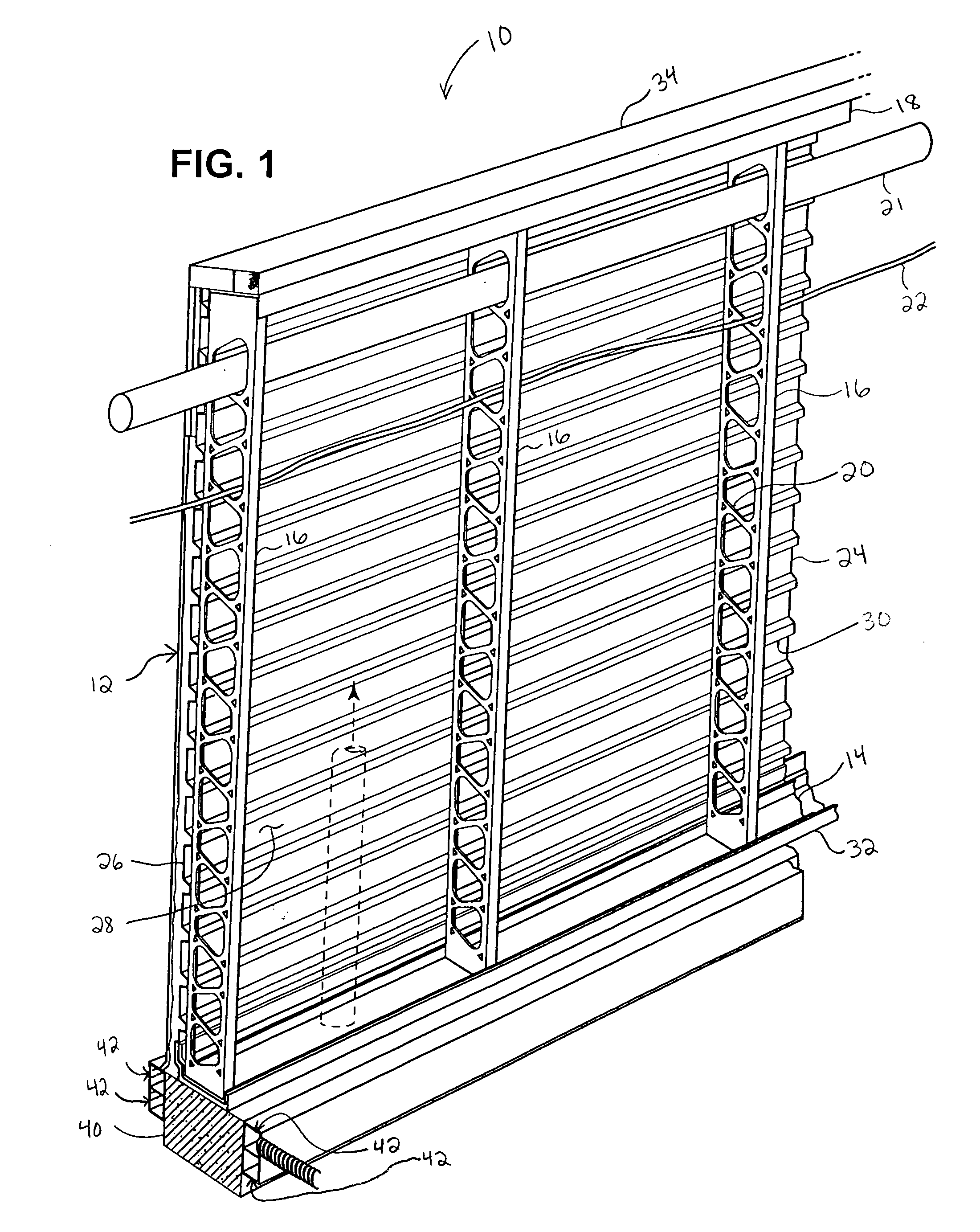

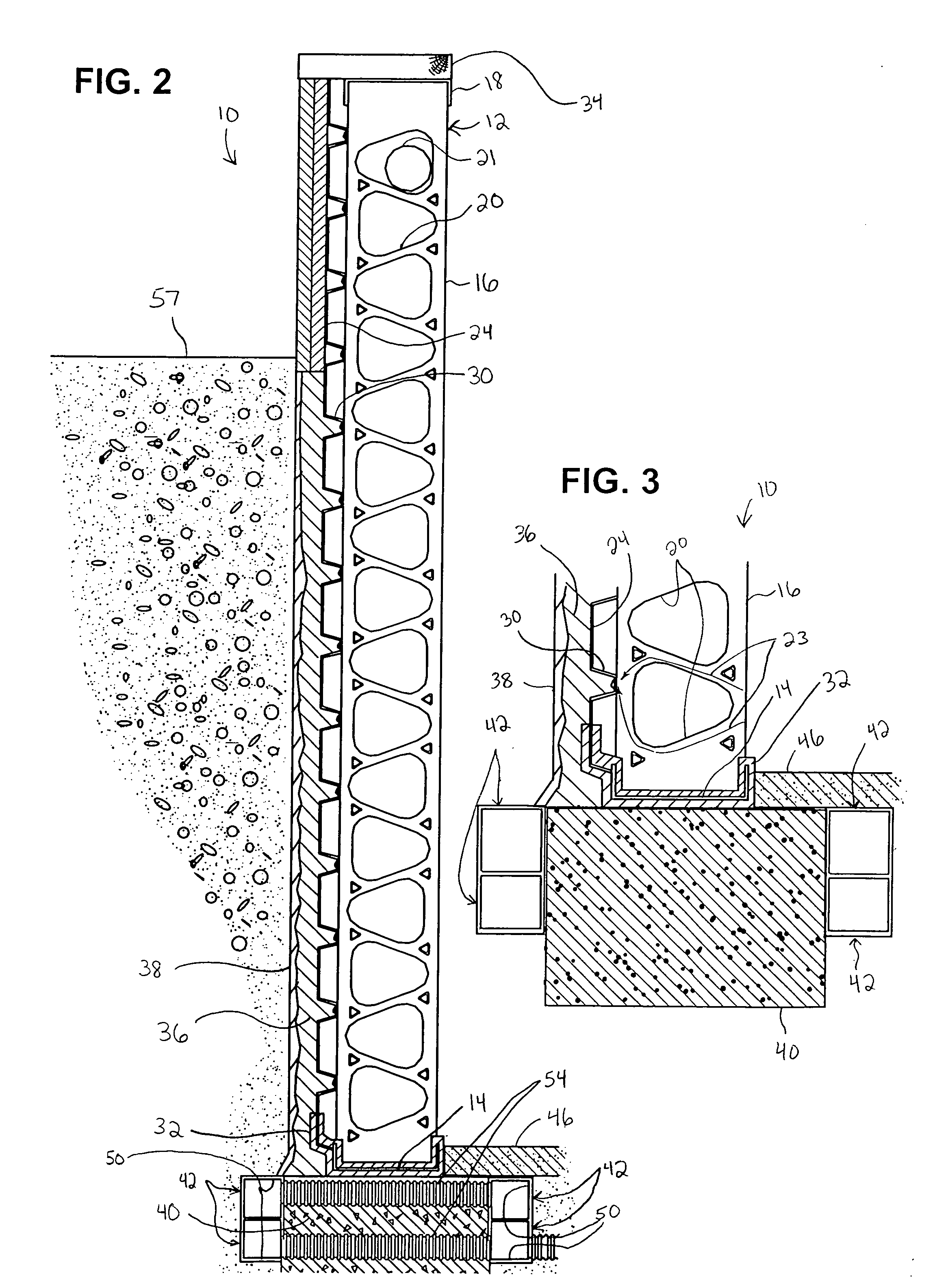

[0022]Referring now to the drawings in detail, numeral 10 generally indicates a basement wall system in accordance with the invention. Turning first to FIGS. 1 through 3, the basement wall system 10 includes a plurality of connected panels 12. Each panel 12 includes a lower metal C-channel 14 having a horizontally disposed base portion, an outside vertically disposed flange portion, and an inside vertically disposed flange portion. The C-channel 14 defines an end of the panel 12. A plurality of vertically disposed metal studs 16 extend upwardly from the base portion of the C-channel. The lower end of each stud 16 generally fits snugly between the inside and outside flange portions of the lower C-channel 14. The studs 16 may be fixed to the C-channel 14, such as by welding. All welds may be coated, such as by spraying, with a rust inhibitor. The basement wall system 10 also includes an upper C-channel 18 having a horizontally disposed middle portion, an outside vertically disposed fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com