Refrigerant storage in LNG production

a technology of refrigerant and lng, which is applied in the direction of liquefaction, lighting and heating equipment, container discharge methods, etc., can solve the problems of flammability of refrigerant and a great danger to the crew, and achieve the effect of safe and convenient storag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

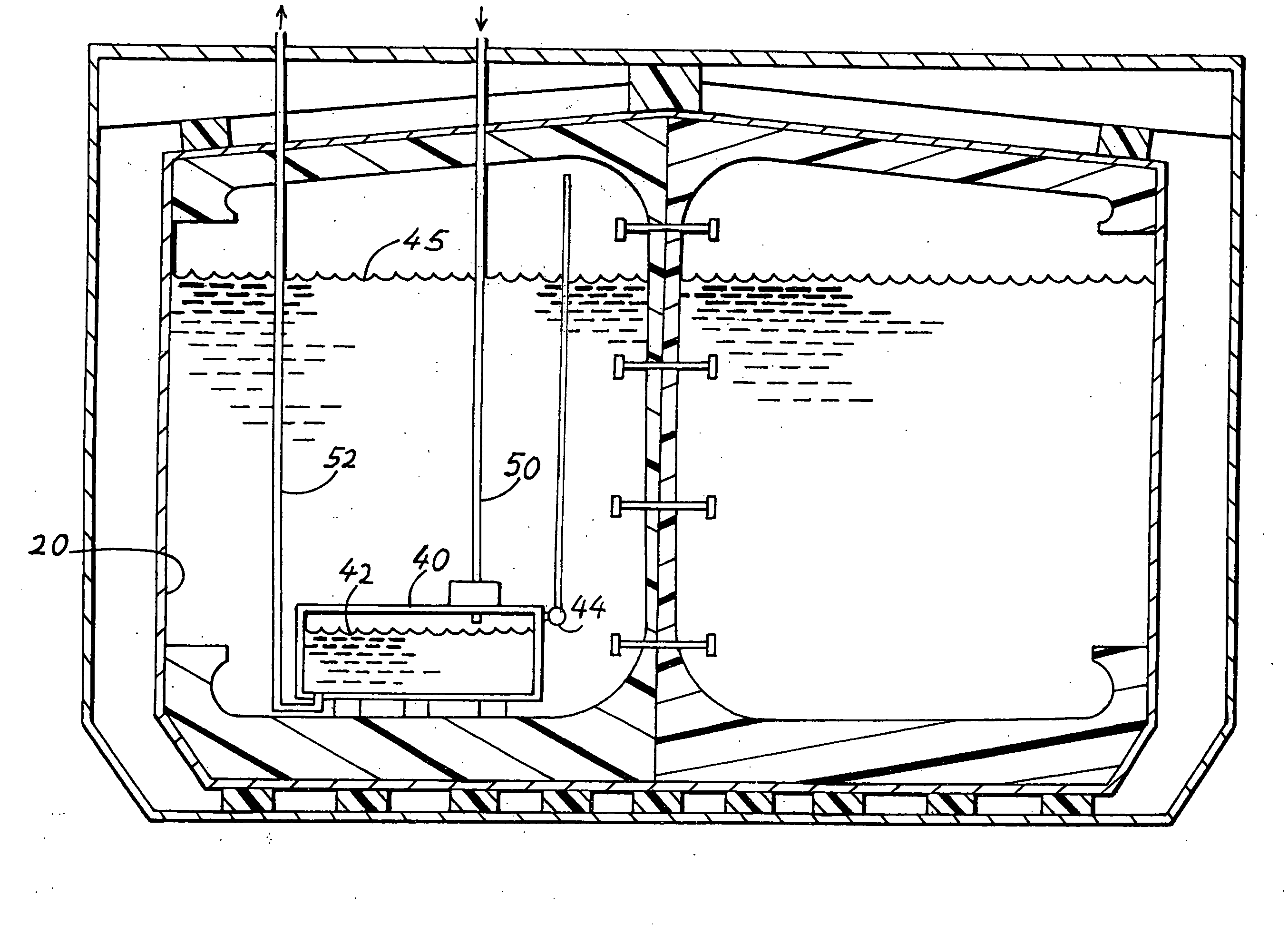

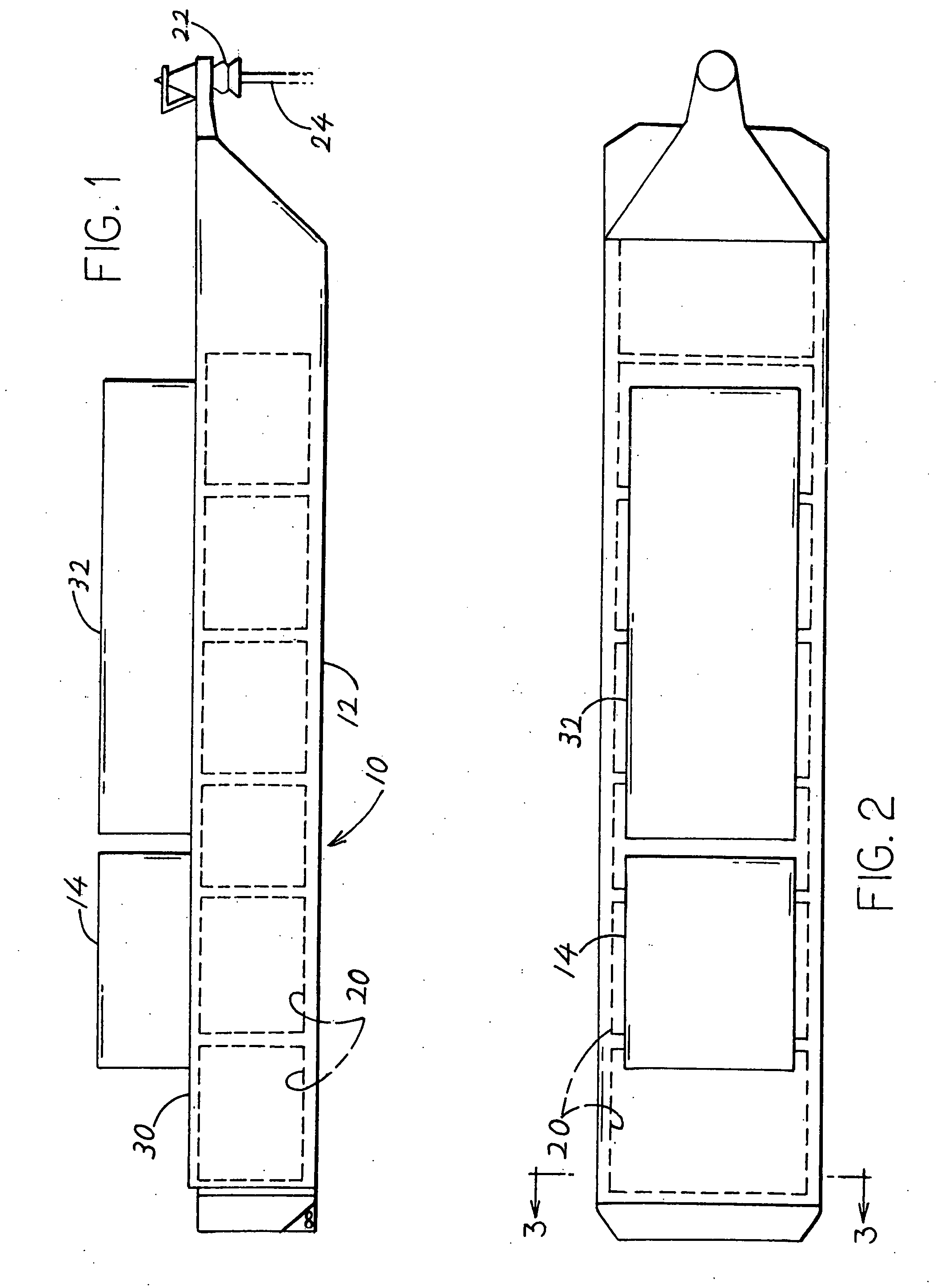

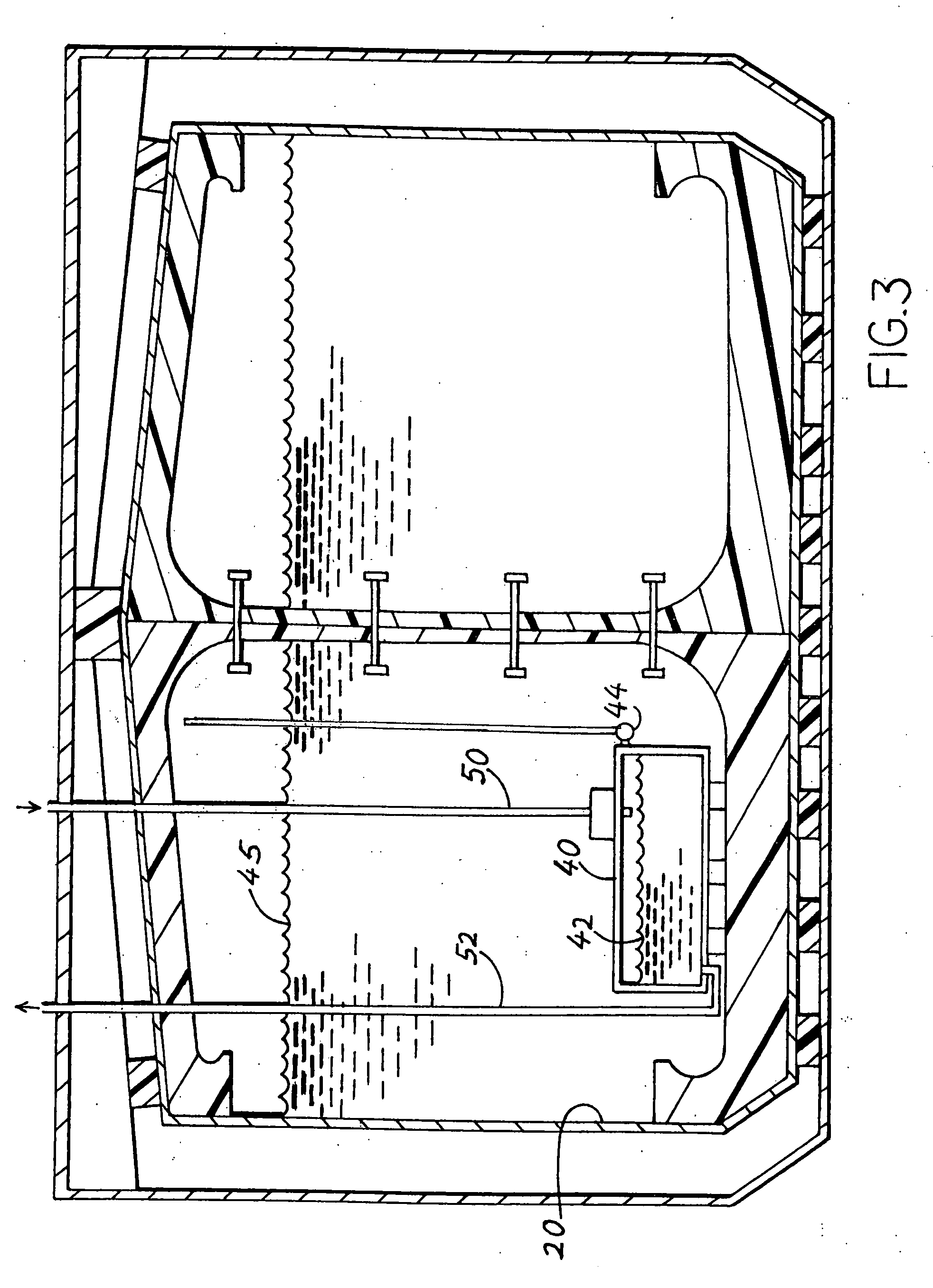

[0014]FIG. 1 illustrates a floating structure 10 of the invention which has a hull 12 that supports refrigeration equipment 14 that is used to cool produced natural gas to about −163° C. to turn it into LNG (liquefied natural gas). The hull holds LNG tanks 20 that hold the LNG until a shuttle tanker sails to the vicinity of the floating structure 10 and moors close by so LNG can be transferred to the tanker. The tanker then carries the LNG at least a few hundred kilometers to a location where the LNG is offloaded and heated to provide natural gas. Both the floating structure and tanker have LNG tanks that can store on the order of magnitude of 200,000 cubic meters of LNG. The floating structure of FIG. 1 has a turret 22 at its bow that allows the floating structure to weathervane while produced natural gas is received through a riser 24. The natural gas is usually cleaned of sand, water, and other impurities before it is liquefied by the refrigeration equipment.

[0015]The refrigerati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com