Chip-Stacked Package Structure and Applications Thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]The foregoing aspects and many of the attendant advantages of this invention will become more readily appreciated as the same becomes better understood by reference to the following preferred embodiments of chip-stacked package structures.

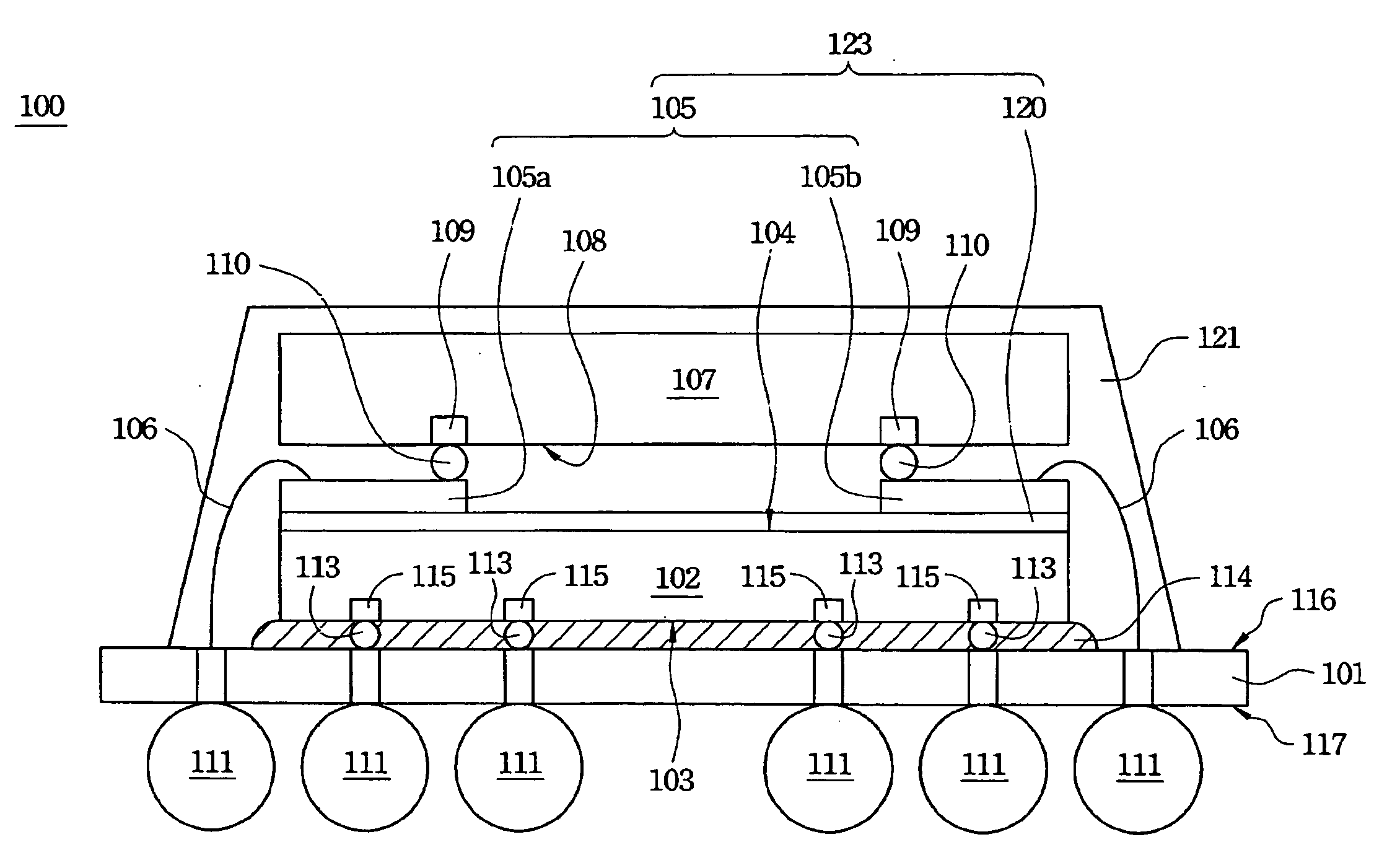

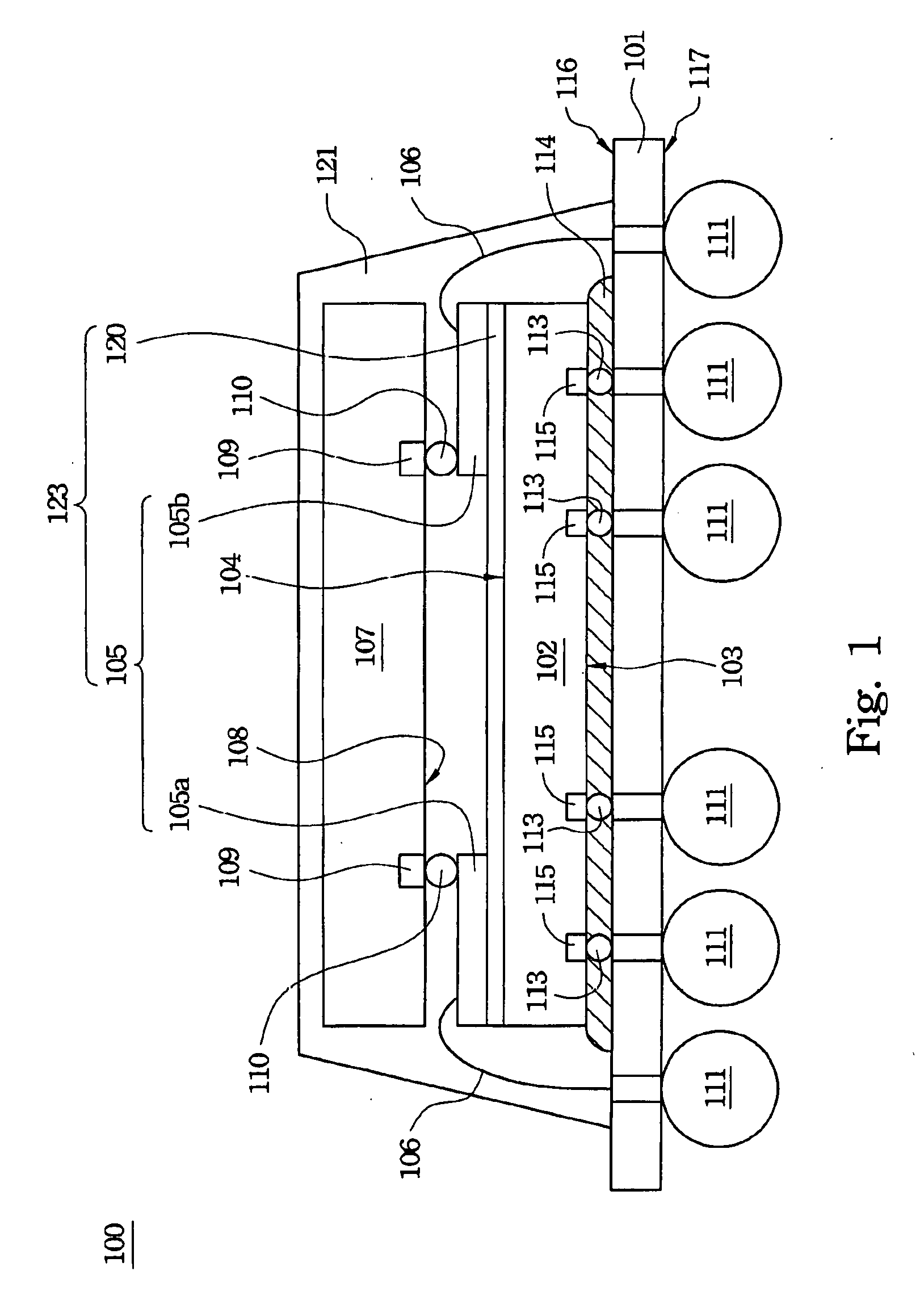

[0019]FIG. 1 illustrates a cross section view of a chip-stacked package structure 100 in accordance with a first preferred embodiment of the present invention.

[0020]The chip-stacked package structure 100 comprises a substrate 101, a first chip 102, a circuit board 123, a second chip 107 and a molding compound 120.

[0021]The chip-stacked package structure 100 is formed by the following steps: First, the substrate 101 having a first surface 116 and a second surface 117 opposite to the first surface 116 is provided. In some preferred embodiments of the present invention, the substrate 101 can be a lead frame, a printed circuit board or a die carrier. In the present embodiment, the substrate 101 is a printed circuit board made of FR4 or BT epoxy, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com