Combined reactor and method for the production of synthetic fuels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

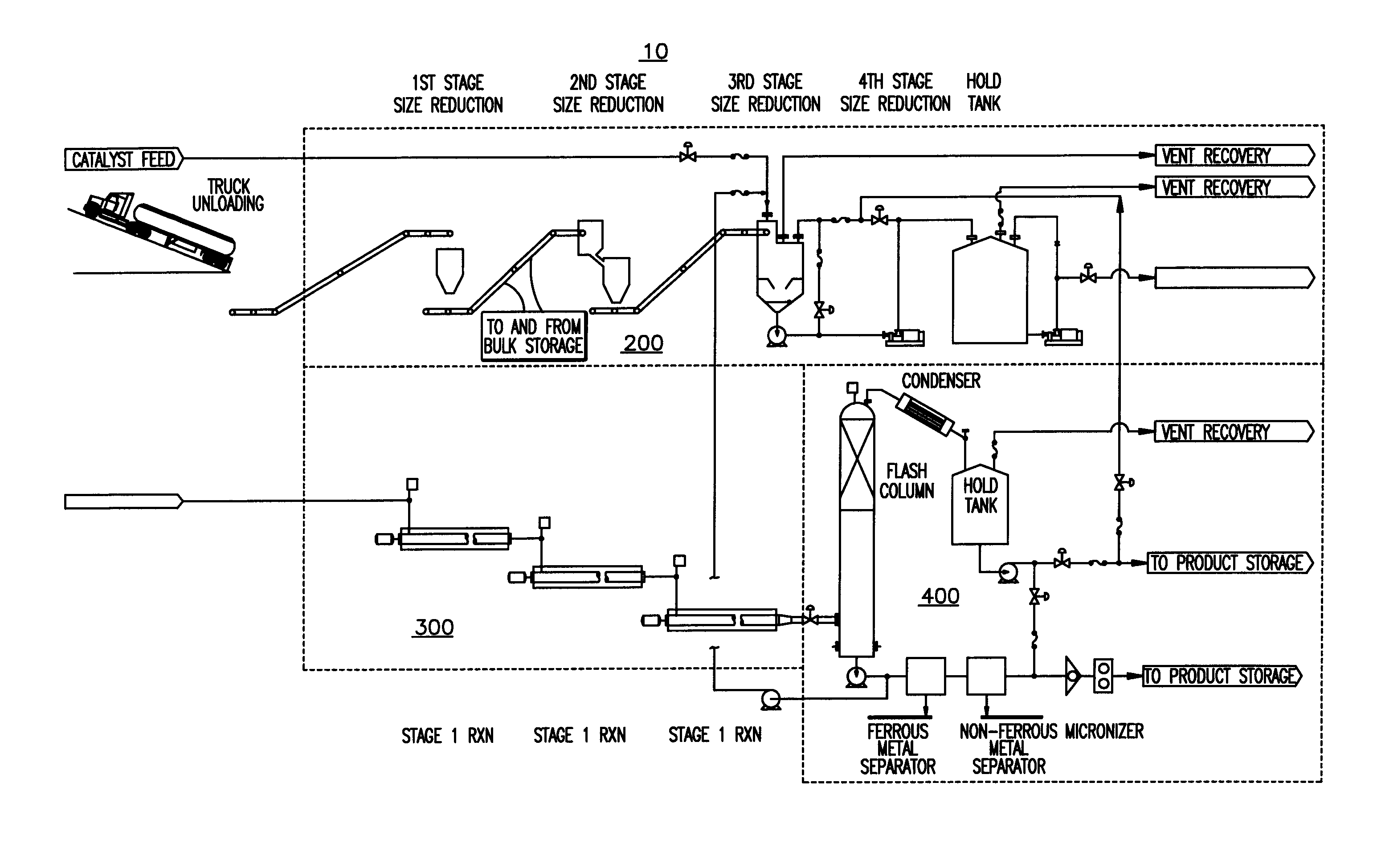

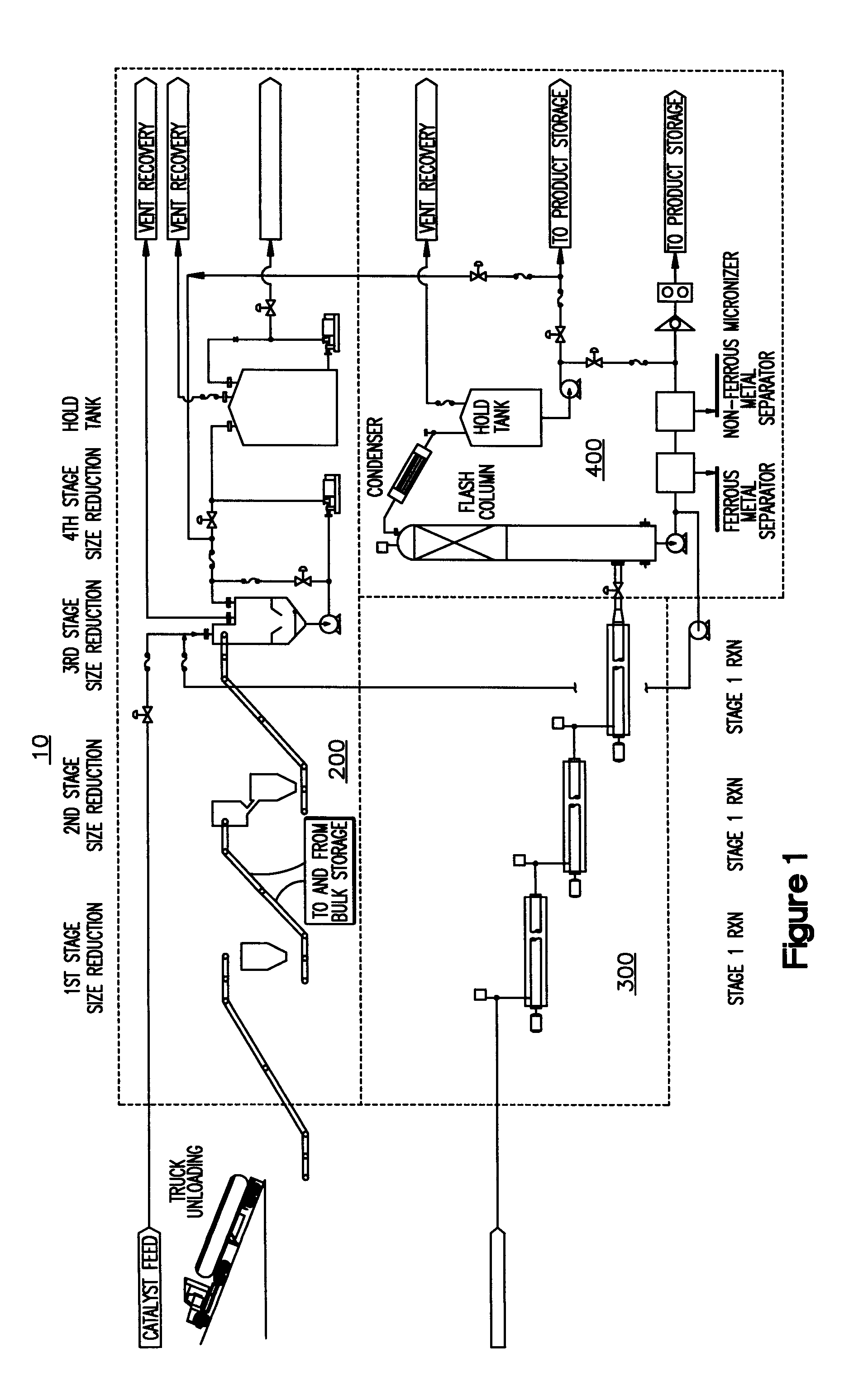

[0029]FIG. 1 is a schematic view of a fuel production plant 10 in accordance with a preferred embodiment of the invention. Plant 10 comprises three general process sections: a size reduction section 200, a reaction section 300 and a finishing section 400, each shown in greater detail in FIGS. 2, 3 and 4, respectively.

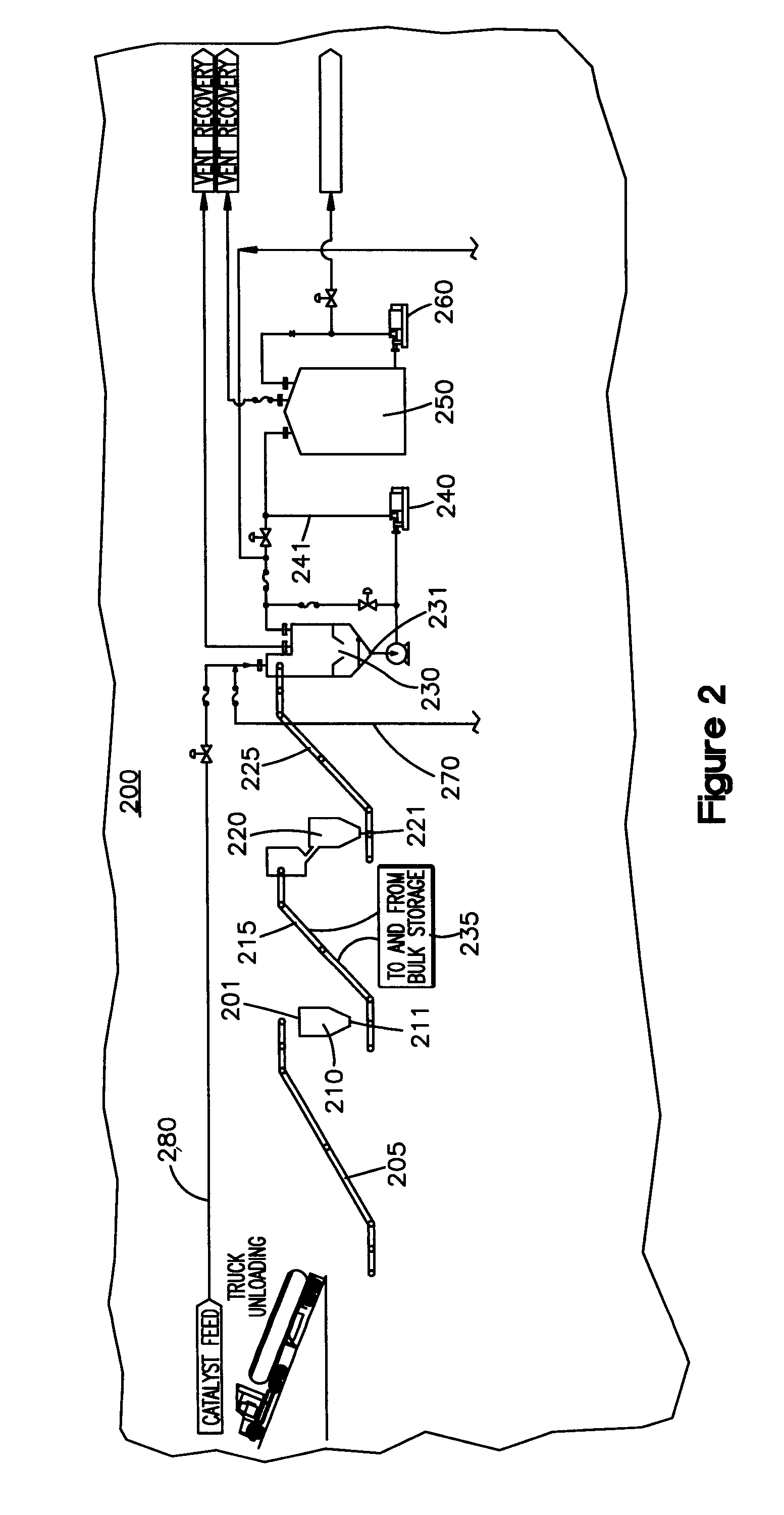

[0030]A preferred embodiment of the invention comprises a size reduction step having multiple stages to gradually reduce the size of the feedstock to the desired particle size. Referring to FIG. 2, size reduction section 200 preferably comprises a first stage size reduction grinder 210, a second stage size reduction grinder 220, a third stage size reduction grinder 230, a fourth stage size reduction safety grinder 240 and a slurry storage tank 250. Acceptable grinders in accordance with preferred embodiments of the invention include the MultiShear and Arde Barinco brand grinders, from MultiShear Corporation of Graniteville, S.C. and Arde Barinco, Inc. of Norwood, N.J.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com