Method for the production of synthetic fuels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

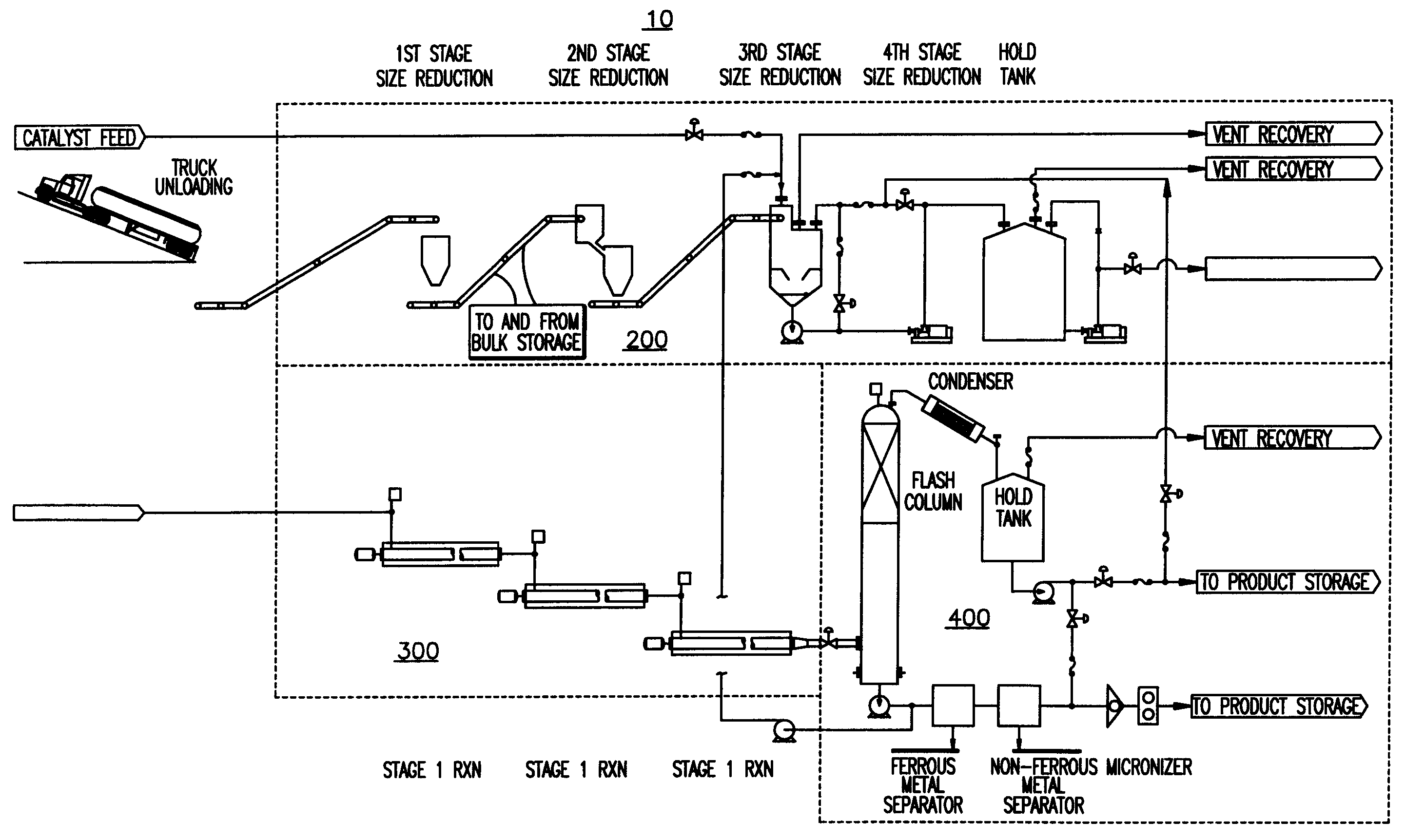

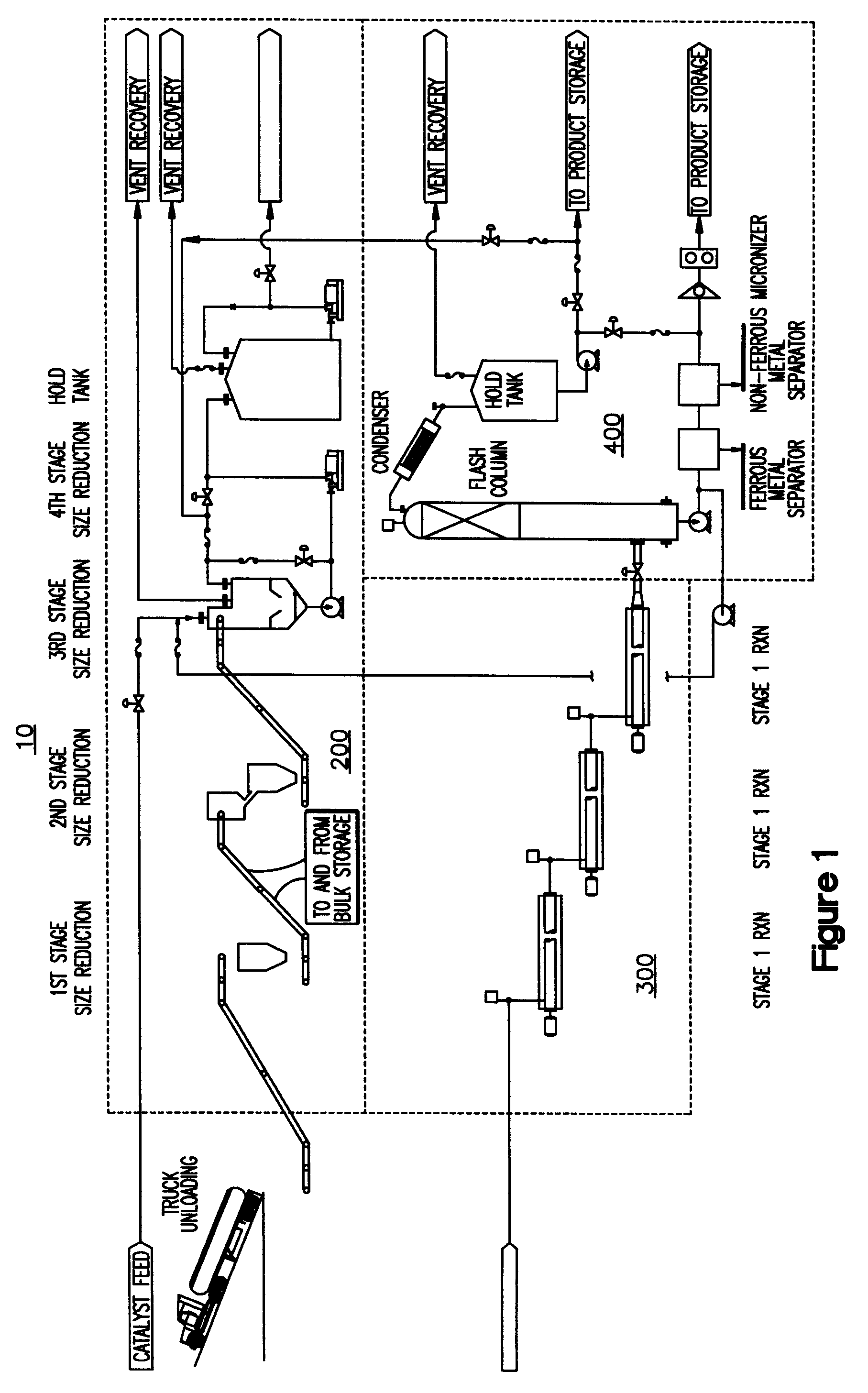

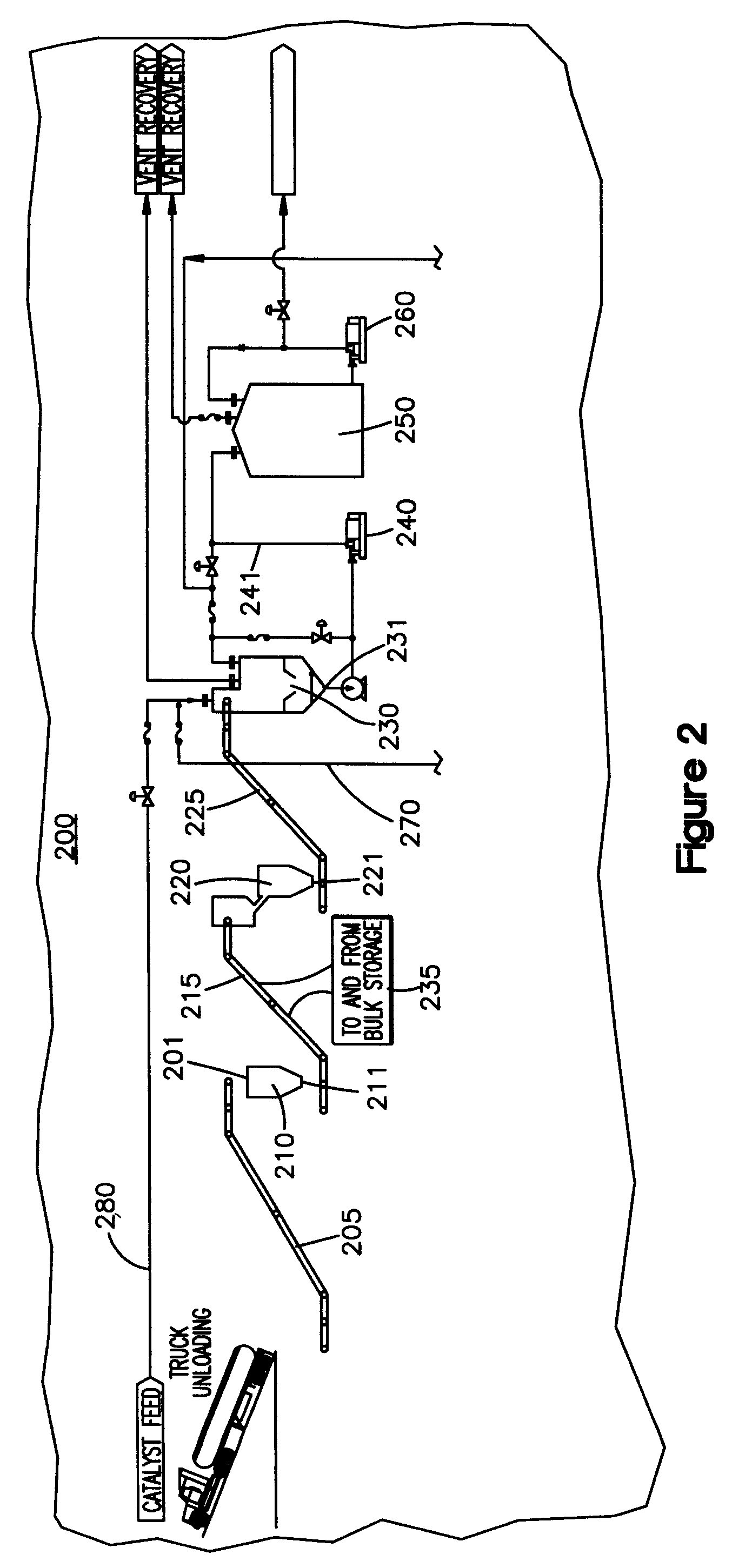

Method used

Image

Examples

example i

[0059]

Feedstock75 g (30% wood, 30% hay, 15% switchgrass, 25% styrene / butadiene polymericplastic)Feedstock particle sizeMoisture content15%Initiator25 g of iron (Fe)Initiator particle sizeSolventMixture of organic liquids (alkanes ofcarbon number C5 to C21)Polymerization temperature700-800° F.Polymerization duration3-20 minutesProduct95% C3 to C21 molecules, 5% carbonnumber greater than 21

example ii

[0060]

Feedstock100 g of pure wood celluloseFeedstock particle size500 microns or lessMoisture content20%Imitator10 g of copper (Cu) and 10 g of zinc (Zn)Initiator particle sizeSolvent100 g of diesel fuelPolymerization temperature600° F.Polymerization duration10 minutesProduct93% C6 to C12 alkanes and alkanols, 7%C12 to C21 alkanes and alkanols

example iii

[0061]

Feedstock100 g of hayFeedstock particle sizeMoisture content7%Imitator5 g of platinum (Pt)Initiator particle sizeSolvent100 g of combined liquid products ofExample I and Example IIPolymerization temperature850° F.Polymerization duration15 minutesProduct94% C6 to C12 alkanes and alkanols, 6%C12 to C18 alkanes and alkanols

[0062]The above examples show the variety of feedstocks that can be used in the system to produce different synthetic fuels in accordance with the invention. The type of synthetic fuel produced can be controlled by the type of initiator used as well as reaction conditions such as those within third reactor 330. It is understood that in first and second reactors 310, 320, the feedstock is substantially liquefied by breaking intermolecular bonds using increased temperature and the reaction between the water and metal catalyst initiators. Feedstock is broken into short chain hydrocarbon radicals, ready to combine with others and polymerize. In third reactor 330, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com