Continuous counter-current organosolv processing of lignocellulosic feedstocks

- Summary

- Abstract

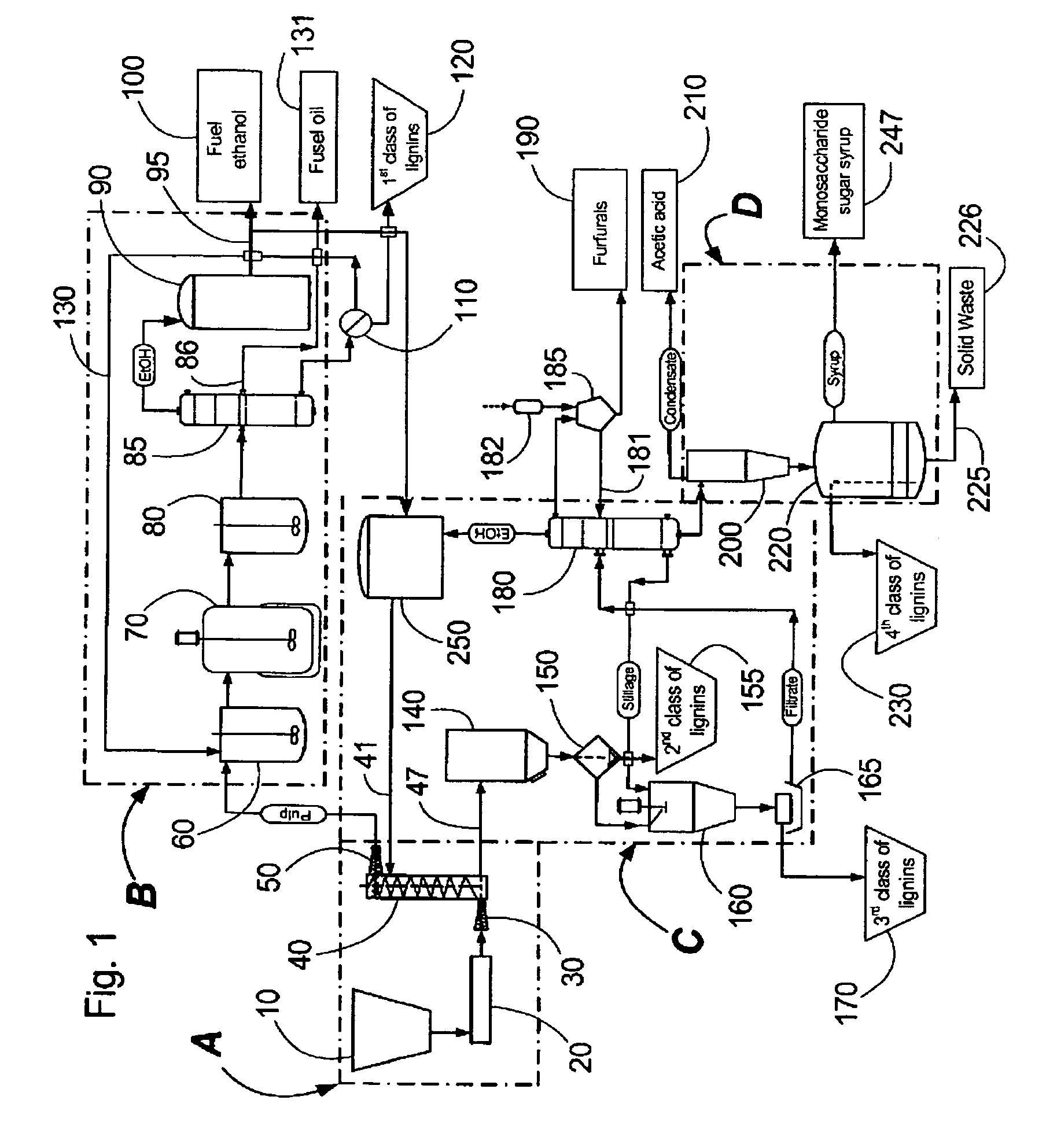

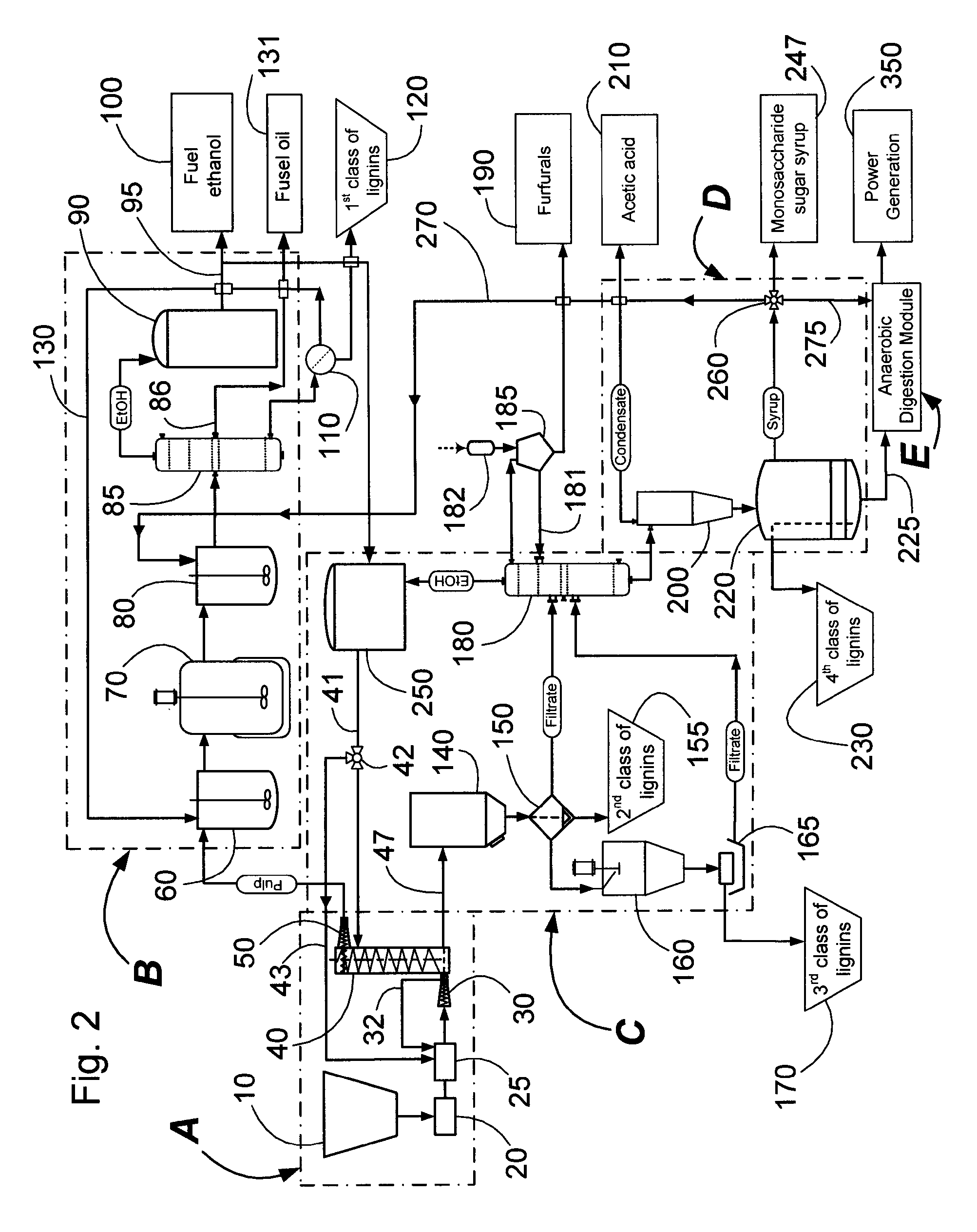

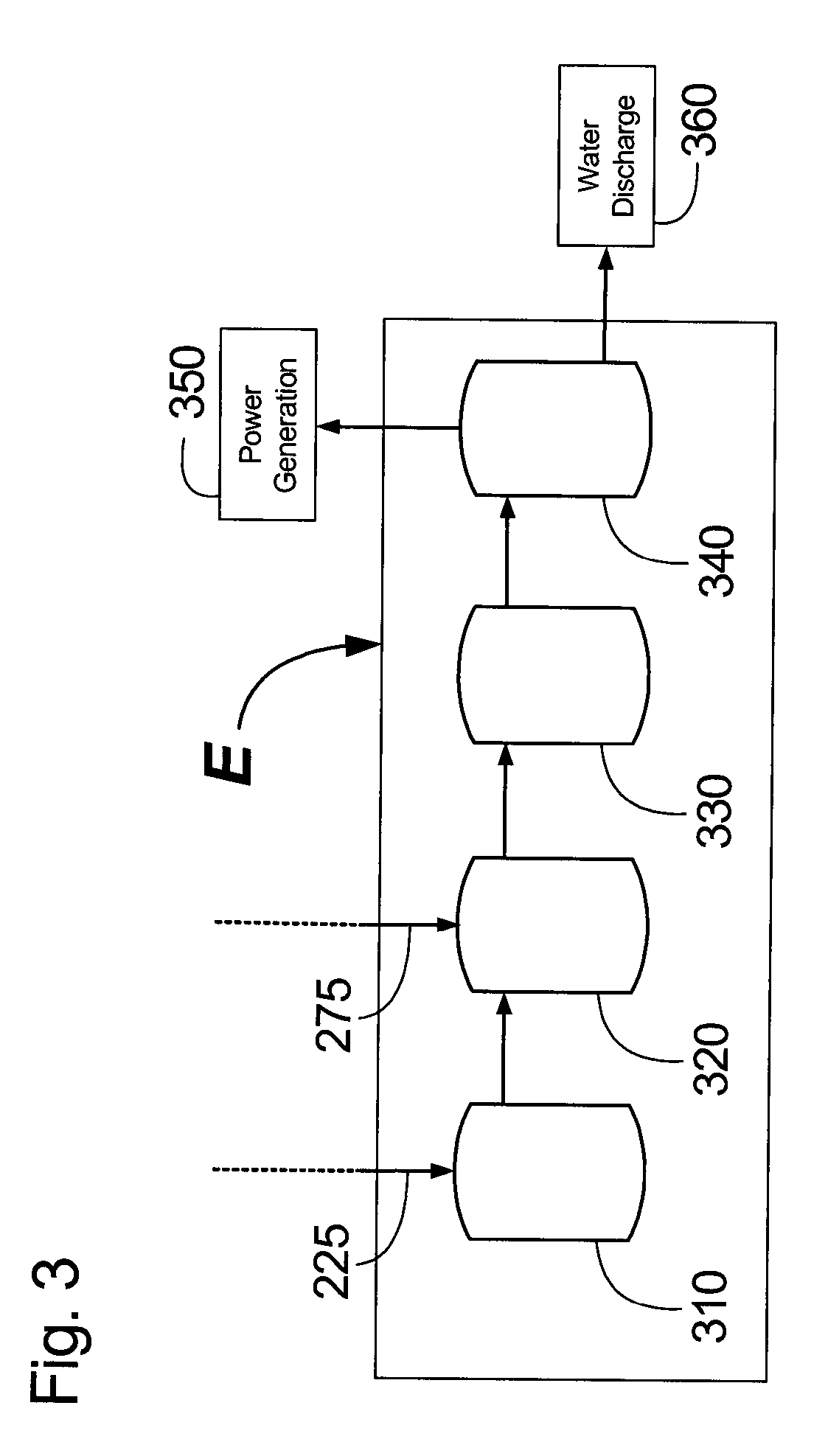

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0059]Representative samples of whole logs of British Columbian aspen (Populus tremuloides) (˜125 years old) were collected. After harvesting, logs were debarked, split, chipped, and milled to a chip size of approximately ≦10 mm×10 mm×3 mm. Chips were stored at room temperature (moisture content at equilibrium was ˜10%). The aspen chips were organosolv-pretreated in aqueous ethanol (50% w / w ethanol) with no addition of exogenous acid or base, in a 2-L Parr® reactor (Parr is a registered trademark of the Parr Instrument Company, Moline, Ill., USA). Duplicate 200 g (ODW) samples of the aspen chips, designated as ASP1, were cooked at 195° C. for 60 min. The liquor:wood ratio was 5:1 weight-based. After cooking, the reactor was cooled to room temperature. Solids and the spent liquor were then separated by filtration. Solids were intensively washed with a hot ethanol solution (70° C.) followed by a tap water wash step. The moisture content of the washed pulp was reduced to about 40% with...

example 2

[0061]Duplicate 200-g samples of the wood chips prepared in Example 1, designated as ASP2, were used for this study. The aspen chips were organosolv-pretreated in aqueous ethanol (50% w / w ethanol) with no addition of exogenous acid or base, in a 2-L Parr® reactor. Duplicate 200 g (ODW) samples of aspen chips were cooked at 195° C. for 90 min. The liquor:wood ratio was 5:1 (w:w). After cooking, the reactor was cooled to room temperature. Solids and liquids were then separated by filtration. Solids were intensively washed with a hot ethanol solution (70° C.) followed by a tap water wash step. The moisture content of the washed pulp was reduced to about 40% with the help of a hydraulic press (alternatively a screw press can be used). The washed pulp was homogenized and stored in a fridge at 4° C. The chemical composition (hexose, pentose, lignin content) of raw chips, washed, and unwashed pulps was determined according to a modified Klason lignin method derived from the Technical Assoc...

example 3

[0063]Duplicate 200-g samples of the wood chips prepared in Example 1, designated as ASP3, were used for this study. The aspen chips were organosolv-pretreated in aqueous ethanol (50% w / w ethanol) with no addition of exogenous acid or base, in a 2-L Parr® reactor. The duplicate samples of aspen chips were cooked in duplicate at 195° C. for 120 min. The liquor:wood ratio was 5:1 (w:w). After cooking, the reactor was cooled to room temperature. Solids and liquids were then separated by filtration. Solids were intensively washed with a hot ethanol solution (70° C.) followed by a tap water wash step. The moisture content of the washed pulp was reduced to about 40% with the help of a hydraulic press (alternatively a screw press can be used). The washed pulp was homogenized and stored in a fridge at 4° C. The chemical composition (hexose, pentose, lignin content) of raw chips, washed, and unwashed pulps was determined according to a modified Klason lignin method derived from the Technical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com