Smoking article and smoking article filter

a filter and smoking article technology, applied in the field of improved filters, can solve the problems of ineffective removal or reduction of gas phase constituents of mainstream smoke, limited commercial acceptance of carbon filters, and unpleasant taste of carbon-filtered cigarettes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

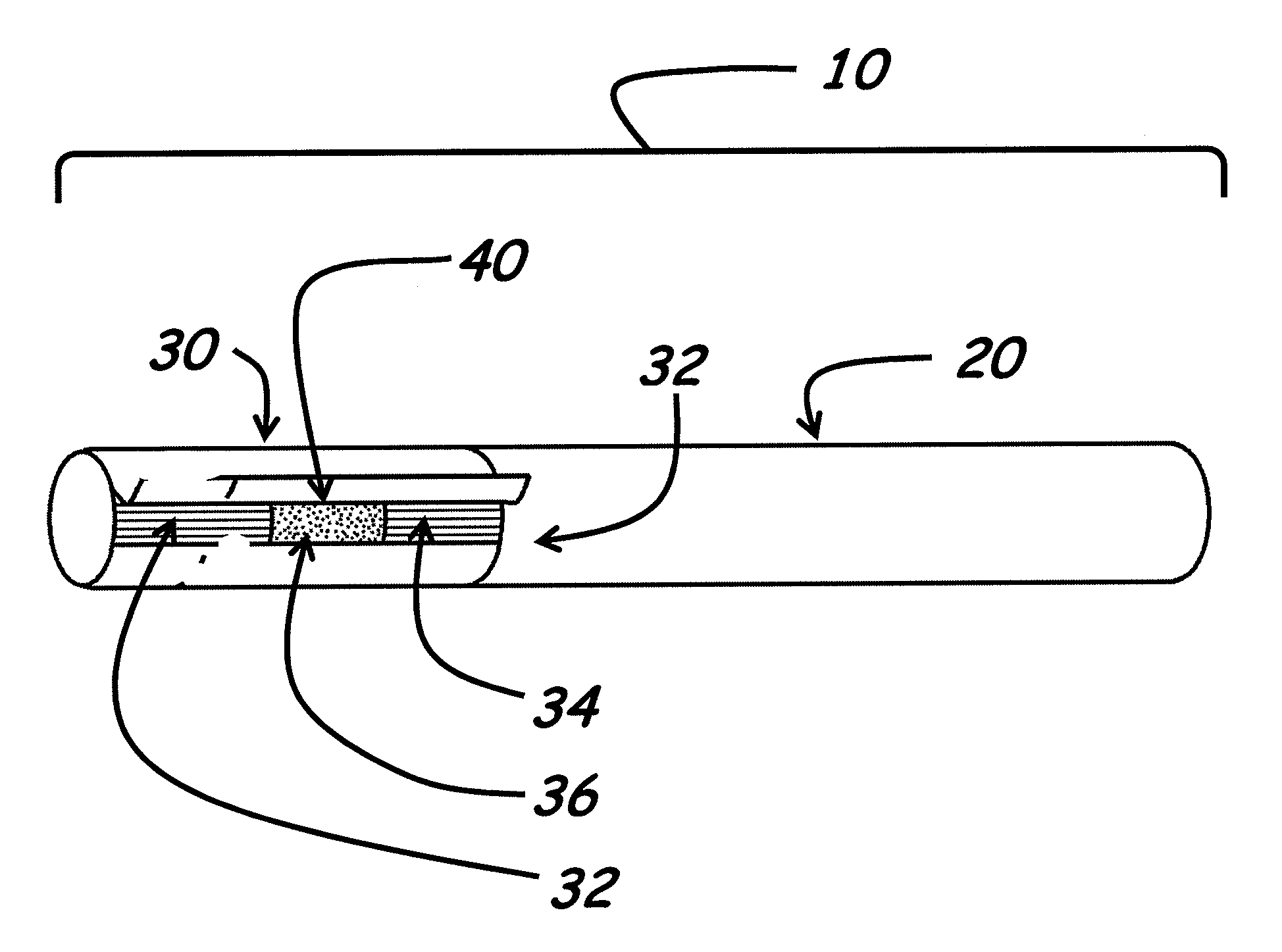

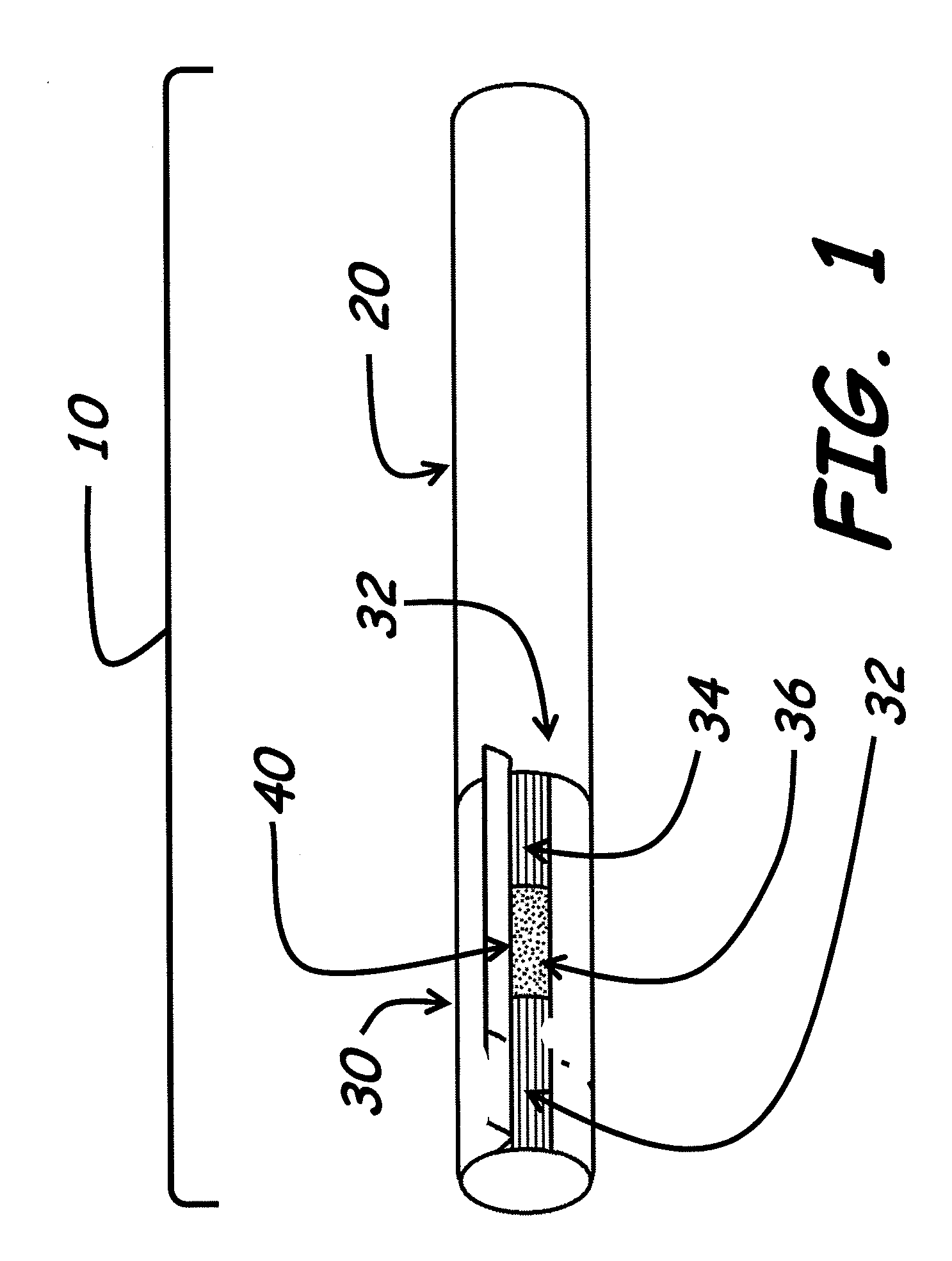

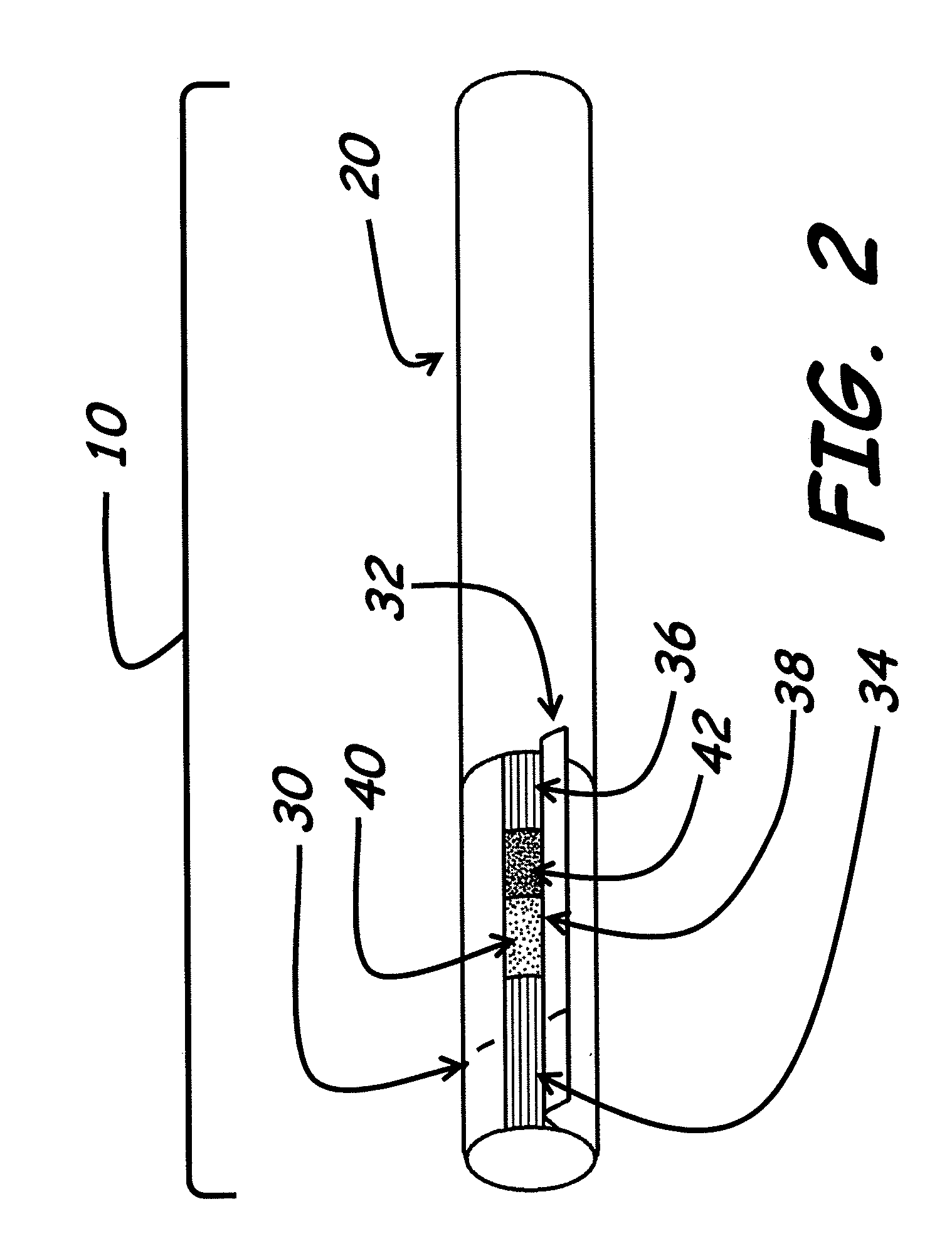

Image

Examples

examples 1-10

[0066]In Examples 1-7 and 10, the lengths of the filter cavities provided are estimated based on the approximate density of the treated activated carbon samples. In a fully loaded condition there will be approximately 25 mg of treated activated carbon per millimeter of cavity length.

[0067]Cigarettes designated as ventilated in the following Examples contained a circumferential row of perforations somewhere along the length of the filter cavity between its upstream and downstream ends.

example 1

[0068]Activated coconut carbon was treated with various materials as listed in Table 1. For all samples listed in this example, PCB (20×50 mesh) activated coconut carbon supplied by Calgon Carbon Corporation (Pittsburgh, Pa.) was used.

TABLE 1ApplicationApplicationMaterial #TreatmentSource **(% wt / total wt)(mmole / gram carbon)1-1Glucosamine hydrochlorideCat #G220-6; Aldrich20.01.161-2Glucose monohydrateCat #49158; Fluka18.71.161-3Lactose monohydrateCat #61339; Fluka29.51.161-4Maltose monohydrateCat #63419; Fluka29.51.161-5SorbitolCat #S375-5; Aldrich4.11.161-6MannitolCat #M-9647; Sigma17.21.141-7FructoseCat #15760; Riedel-de Haën17.21.151-8InositolCat #I6652; Aldrich17.21.161-9Tapioca DextrinCrystal Tex 627; National Starch20.0—1-10ErythritolCat #E-7500; Sigma12.61.181-11Calorie Free Sweetener *Great Value Brand; WallMart18.7—1-12SucroseCat #84097; Fluka28.21.151-13Chitosan oligosaccharide lactateCat #52,368-2; Aldrich16.9—1-14MaltodextrinLodex-10; Mother Murphy's19.9—1-15Hydroxypropy...

example 2

[0072]The following test was conducted to determine the efficacy of various amino acids as off-taste suppressants for use in the present invention. Activated coconut carbon was treated with various materials as listed in Table 3. For all samples listed in this example, PCB (20×50 mesh) activated coconut carbon supplied by Calgon Carbon Corporation (Pittsburgh, Pa.) was used.

TABLE 3ApplicationApplicationMaterial #TreatmentSource *(% wt / total wt)(mmole / gram carbon)2-1AsparagineCat #A9,300-3; Aldrich8.490.702-2GlutamineCat #G-3126; Sigma9.450.712-3GlycineCat #G620-1; Aldrich4.840.68* Aldrich = Aldrich Chemical Company (Millwaukee, WI); Sigma Chemical Company (Millwaukee, WI).

[0073]The activated carbon was treated according to the following general procedure. Each treatment material listed in Table 3 was dissolved in water. Then the resulting solution was applied to the untreated carbon. Sufficient treatment material was added to the water to yield the final application as listed in Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com