Processes and reactors for alkali metal production

a technology of alkali metal and reactor, which is applied in the direction of monoborane/diborane hydrides, manufacturing tools, electrolysis components, etc., can solve the problems of high market price of sodium, high quantity of sodium salt by-products, and increase the cost of sodium borohydride production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

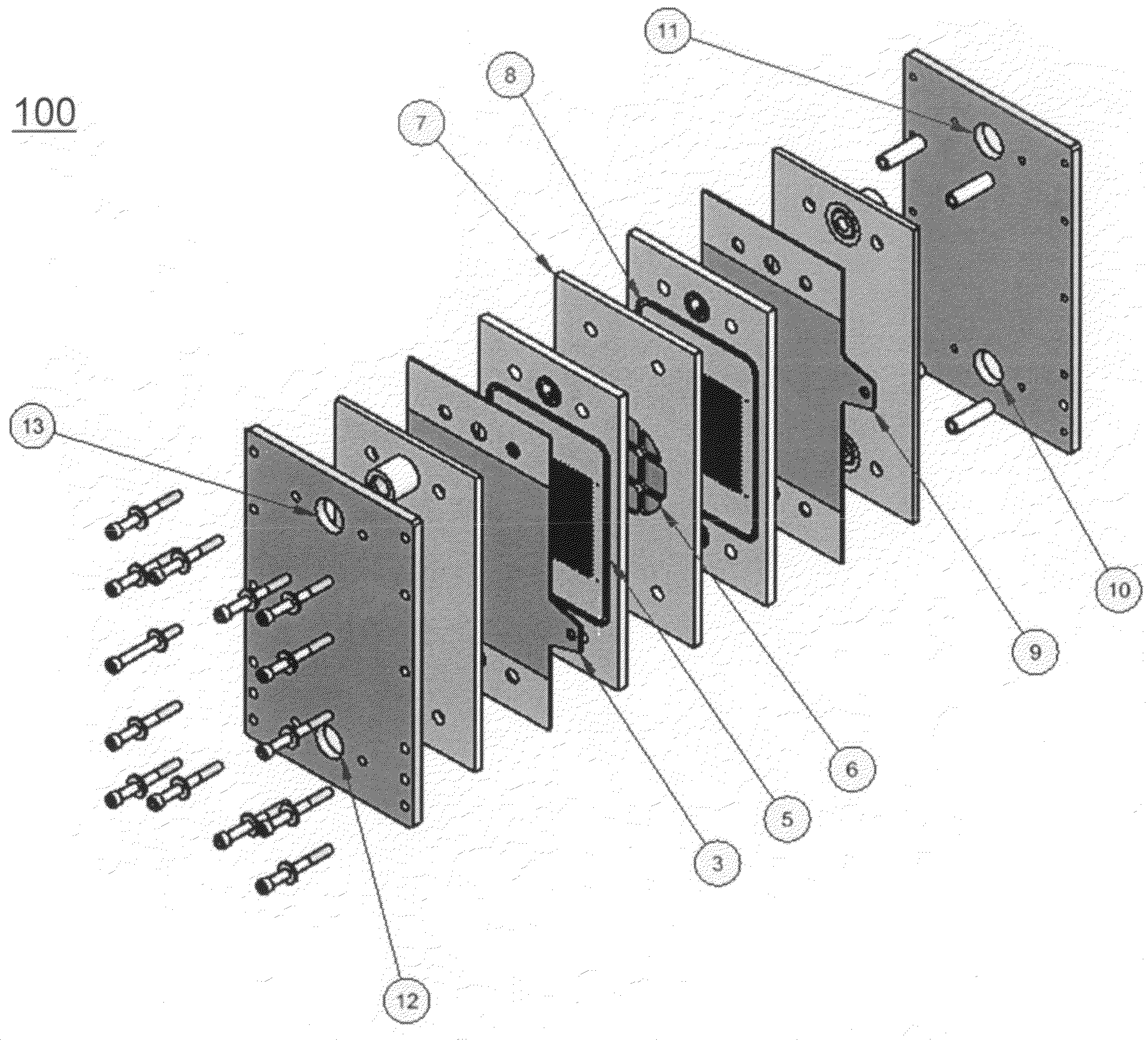

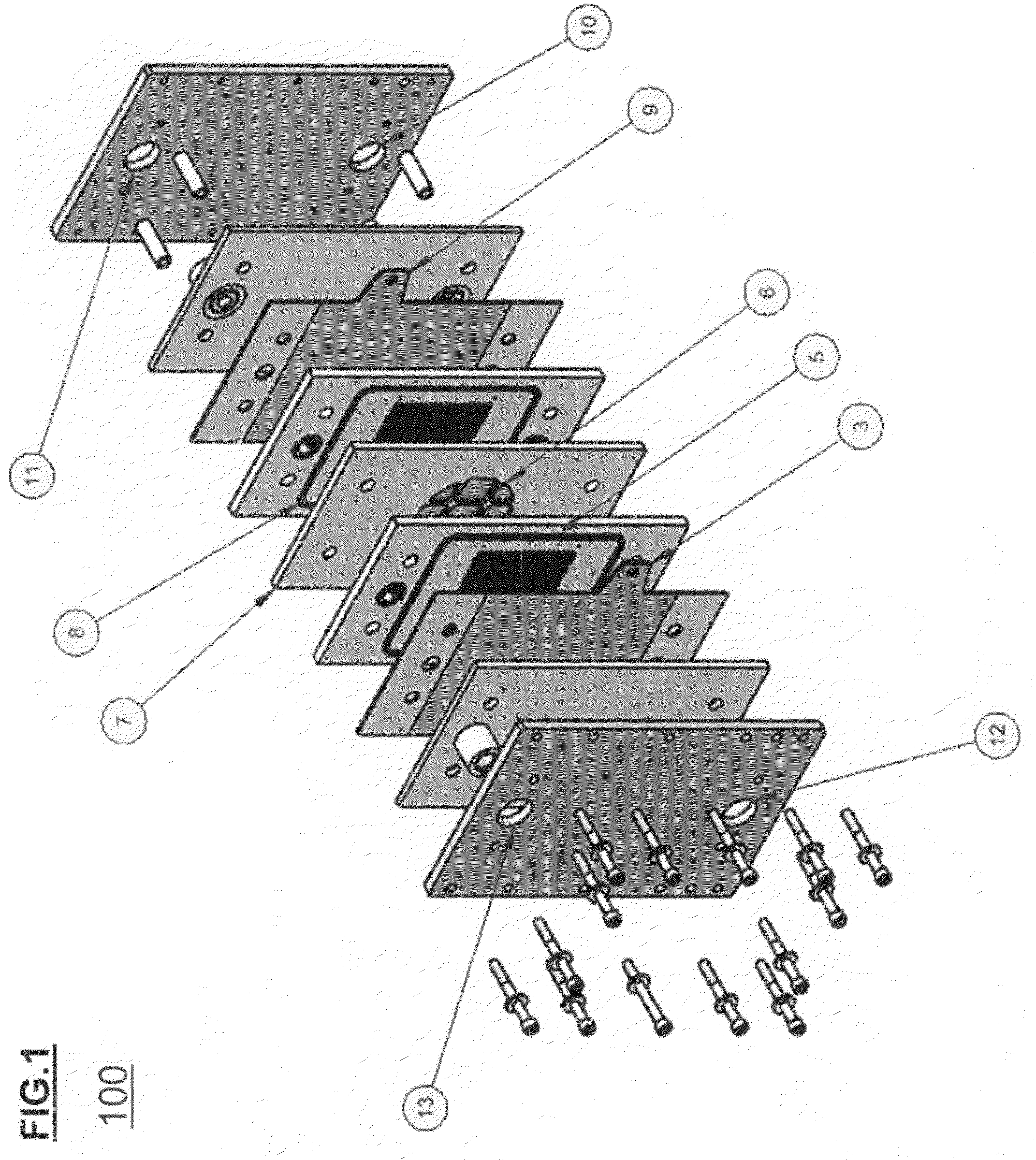

Method used

Image

Examples

example 1

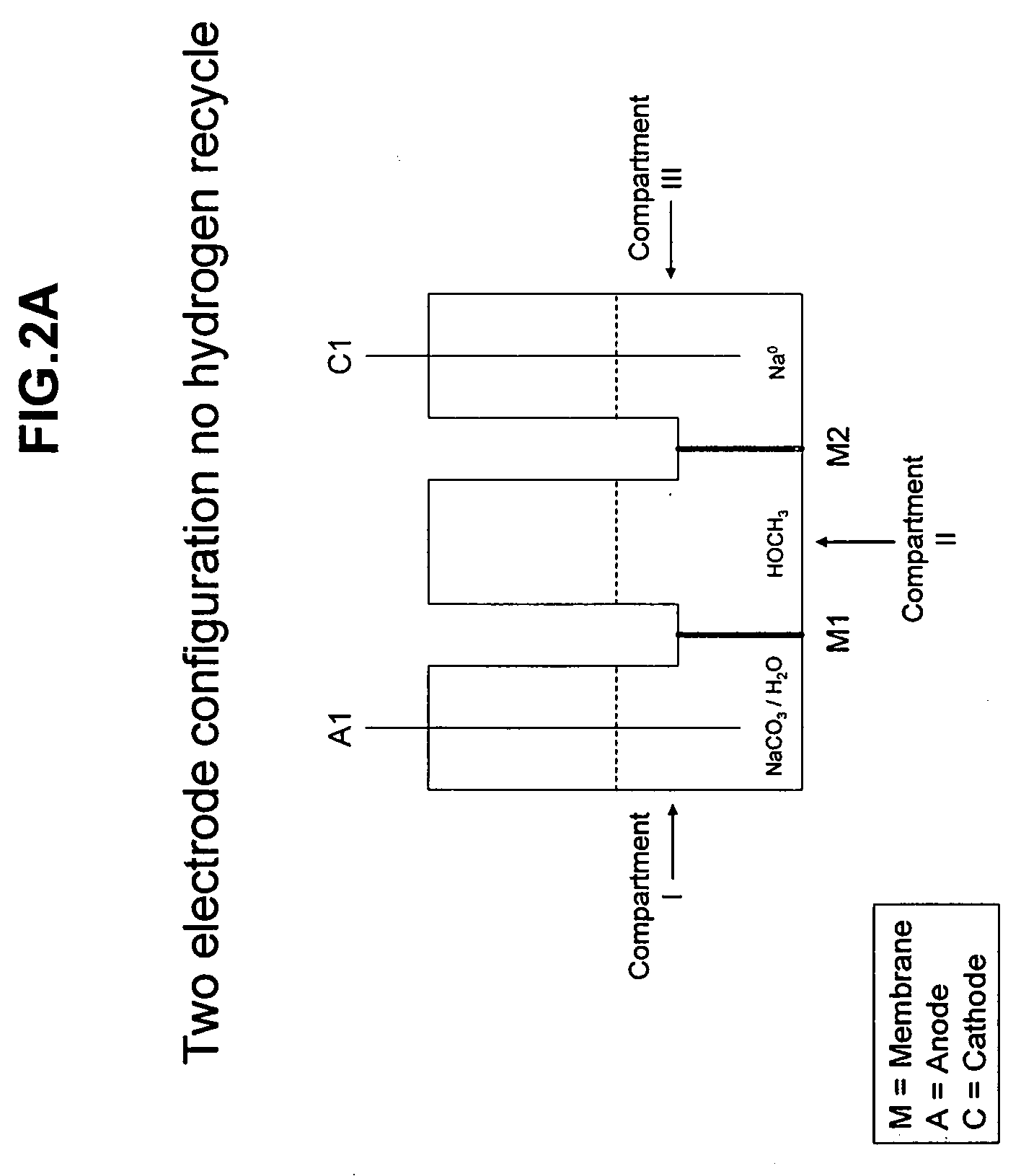

[0058]A reaction flask was charged with a 30 weight % sodium methoxide in methanol solution. A tube with a ceramic membrane bottom was inserted into the solution. The tube bottom comprised the membrane or separator. The volume inside the tube is the cathode compartment and the volume outside the tube, but inside the reaction flask, is the anode compartment. The anode was a Ni-frit with flowing hydrogen gas immersed in the methanolic anolyte. The cathode was a Ni-wire that was immersed within the catholyte which consisted of molten sodium metal.

[0059]The reactor was operated between 110° C. and 120° C. under 10 psig H2 while the sodium metal compartment inside the membrane tube was placed under 10 psig N2. Under these conditions, the sodium in the cathode compartment was molten. After a potential was applied to the cell and the desired amount of current passed through the cell, the cell was cooled to room temperature and the amount of sodium metal that was generated was measured. Sod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| electrical potential | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com