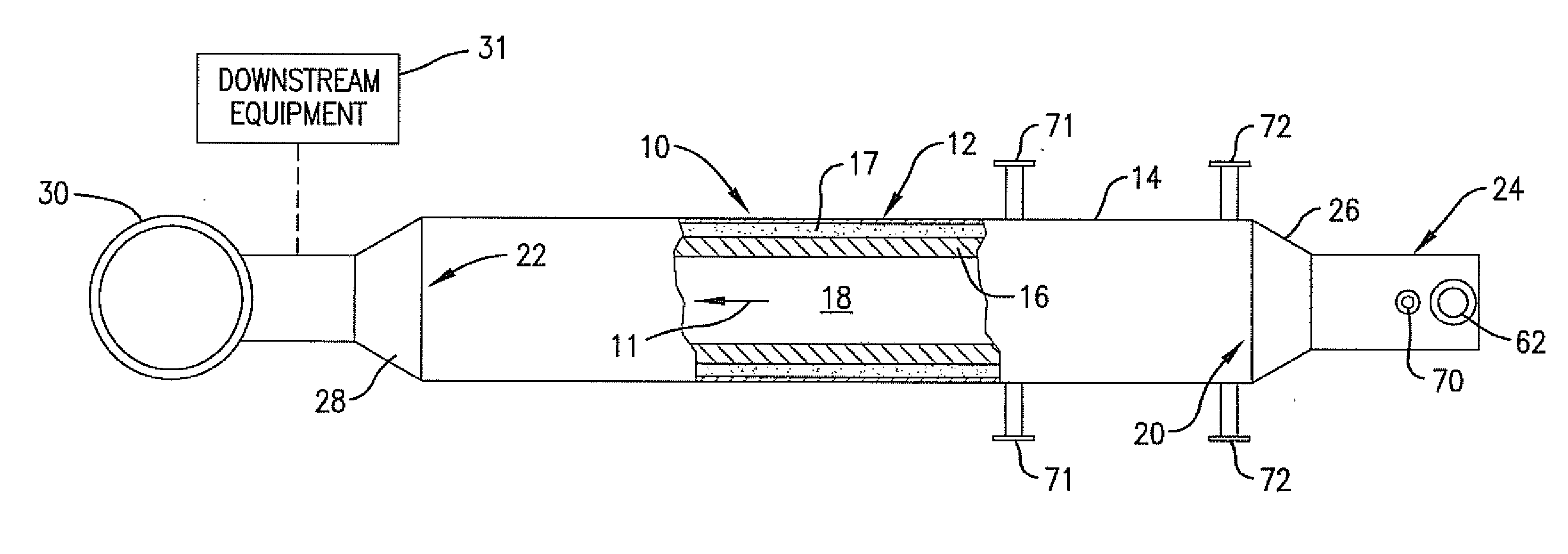

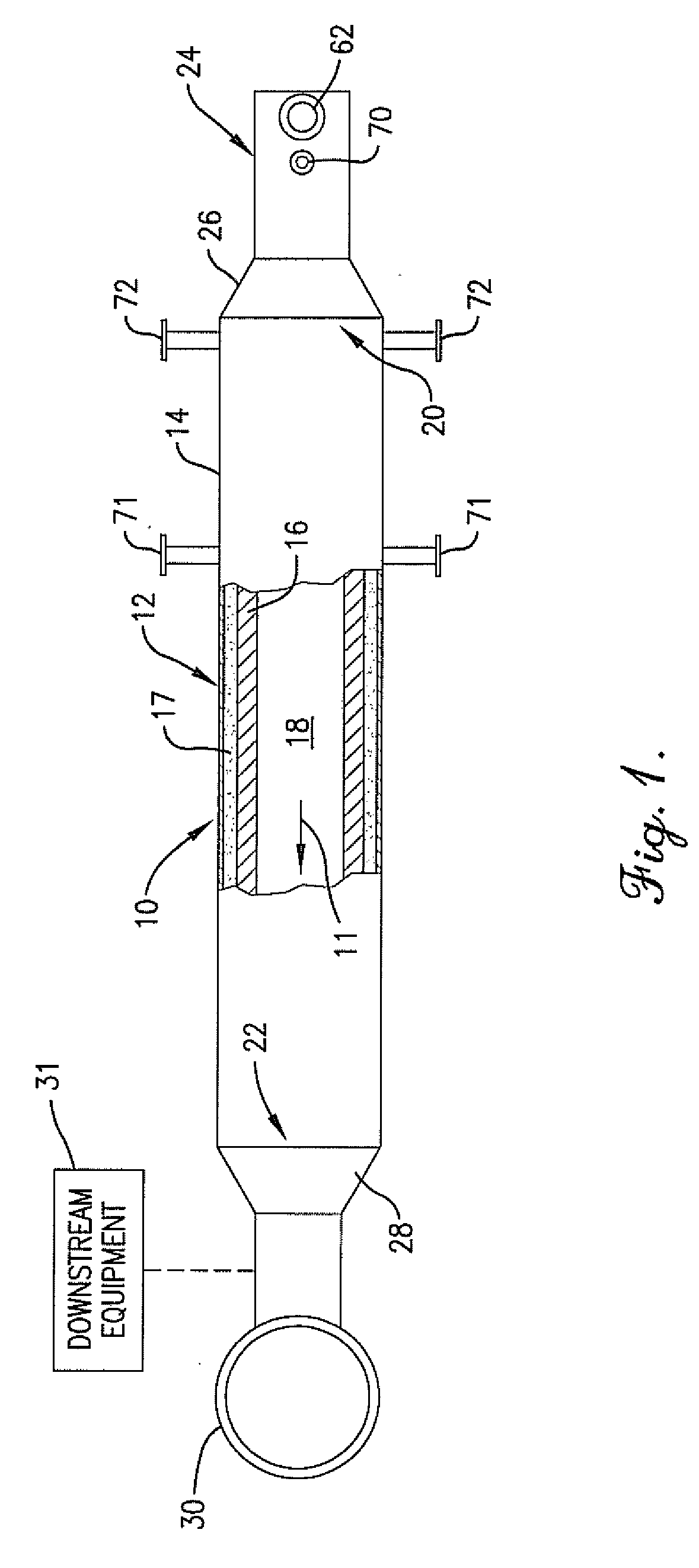

Flameless thermal oxidation apparatus and methods

a thermal oxidation apparatus and flameless technology, applied in the direction of indirect carbon-dioxide mitigation, combustion types, combustion processes, etc., can solve the problems of reducing the open volume available for the flow of the process stream, nox and co, and nox and co production,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

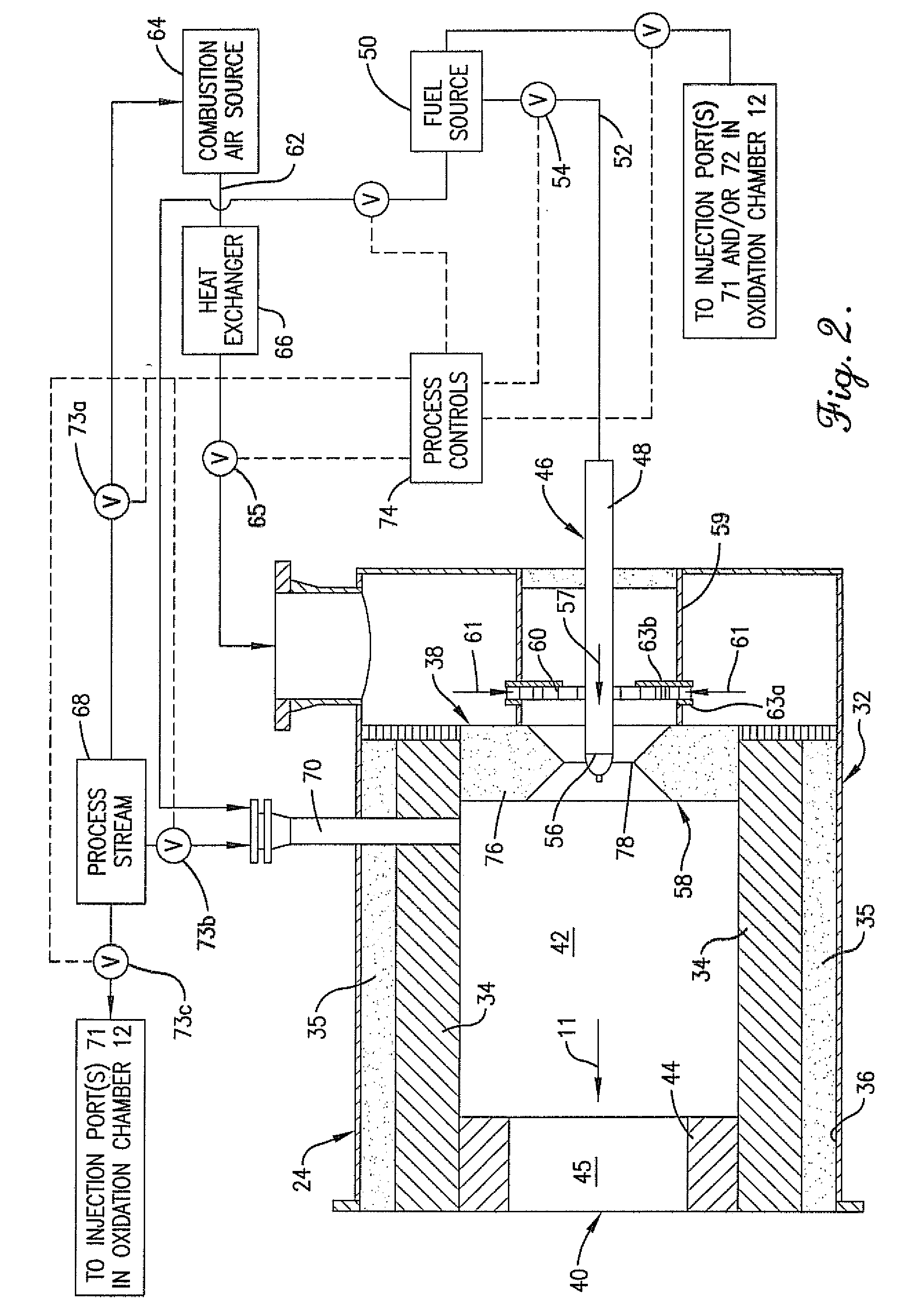

example 1

[0042]Combustion air in the form of air at room temperature was delivered into the antechamber 42 through swirl vanes 60 at a flow rate of 114,000 scf / hr. Fuel in the form of natural gas at room temperature was injected into the antechamber 42 through the fuel tip 56 at a flow rate of 5,550 scf / hr. The fuel and combustion air mixture was ignited and burned with a visible flame until the oxidation chamber 12 reached a temperature of 1,880° F. Once the oxidation chamber 12 was preheated in this manner, the burner flame was extinguished by pulling the fuel tip 56 back from the centerline of the burner throat 78 approximately 3.5 inches to cause more complete mixing of the fuel and combustion air prior to passage of the mixture through the burner throat 78. The fuel and combustion air flow rates remained nearly unchanged and the premix stream of fuel and combustion air passed into the antechamber 42 through the burner throat 78 without a visible flame being present and the combustion ro...

example 2

[0043]The test of Example 1 was repeated with the following changes in parameters: (1) the combustion air flow rate was reduced to 100,200 scf / hr., and (2) the fuel flow rate through the antechamber 42 was reduced by staging the fuel. The total fuel flow was 5,500 scf / hr. and was split with 85.6% of the fuel being premixed with all of the combustion air stream prior to injection into the antechamber 42 and the remaining 14.4% of the fuel being injected through two fuel gas tips 72 positioned in the oxidation chamber 12 just downstream from the burner 24. The fuel injected through the fuel gas tips into the oxidation chamber 12 was combusted with a visible flame and provided direct heating of the refractory lining 16 to stabilize the flameless oxidation process in the oxidation chamber 12. As a result of this increased heat input, the outlet temperature of the oxidation chamber 12 was 1,990° F. Because a portion of the fuel was combusted with a visible flame, the NOx levels increased...

example 3

[0045]The test conditions presented for Example 3 demonstrate a case where, after sufficient preheating of the refractory lining 16, the turbulent flame speed was exceeded to allow for flameless operation above the lower flammability limit of the air / fuel mixture in the antechamber 42. The combustion air flow rate was 245,640 scf / hr., the natural gas flow rate was 18,357 scf / hr., and the thermal oxidizer operating temperature was 2,381° F. The combustion air and natural gas were premixed in the antechamber 42 to yield a 5.87 vol % premixed fuel composition, which was above the ambient temperature lower flammability limit (5 vol %). The oxidation process did not flash back into the antechamber 42, indicating the turbulent flame speed through the reduced diameter passageway 45 was exceeded. The NOx emissions for this process condition were 1.3 ppm dry, with undetectable CO emissions (<1 ppm dry).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com