Methods, apparatuses and systems for processing fluid streams having multiple constituents

a technology of fluid streams and components, applied in lighting and heating apparatus, solidification, refrigeration and liquifaction, etc., can solve the problems of recurring regeneration costs, cost prohibitive to conduct such activities, and easy over-estimation of component gas valu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

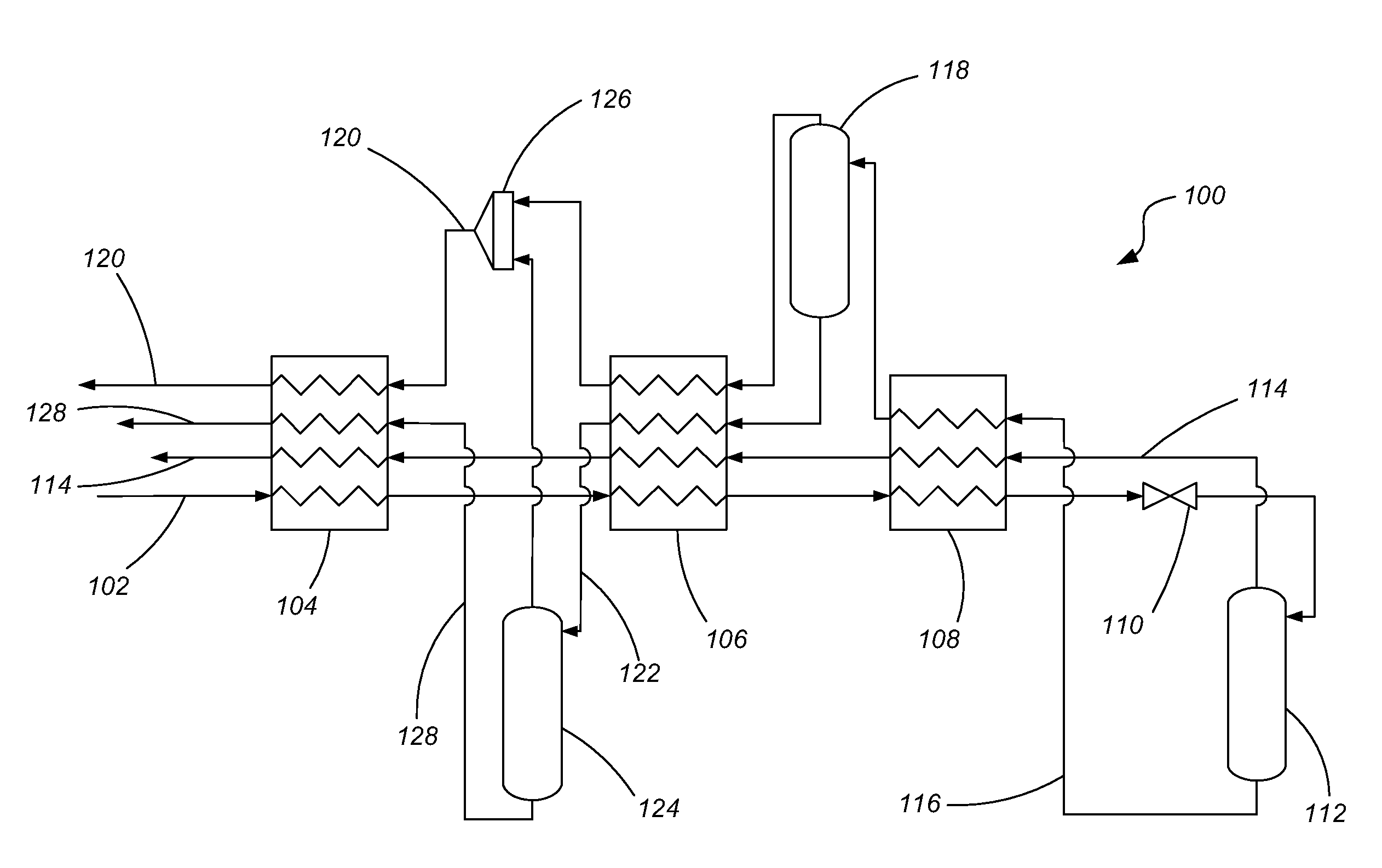

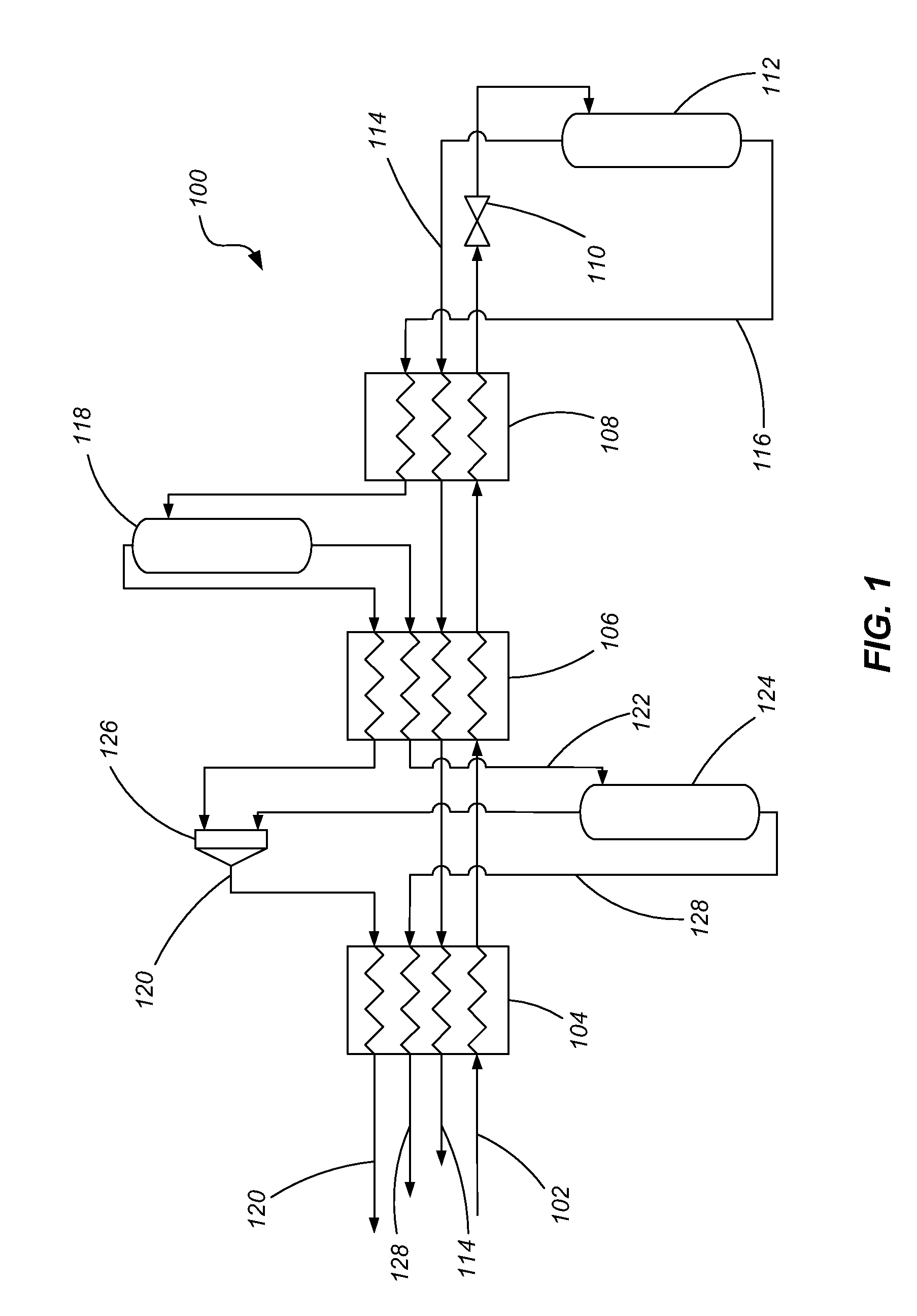

[0053]Modeling has been conducted for a separation plant such as described with respect to FIG. 1. As previously noted, the separation plant 100 described with respect to FIG. 1 is an embodiment that employs a process of separation using an ascending temperature method of separation. In other words, each successive act of separation is conducted at a temperature that is warmer than the previous separation act. It is noted that in this example (as well as in Example 2 described below), minor pressure drops have been ignored in order to simplify the modeling. Those of ordinary skill in the art will recognize that minor pressure drops will occur at the heat exchangers and at various places in the process piping.

[0054]Referring to FIG. 1, conditions or “state points” of fluid flowing throughout the plant 100 are now described.

[0055]Considering such modeling, the feed stream 102 may include a mixed gas including, among other potential constituents, 0.0107 mass fraction of hydrogen, 0.248...

example 2

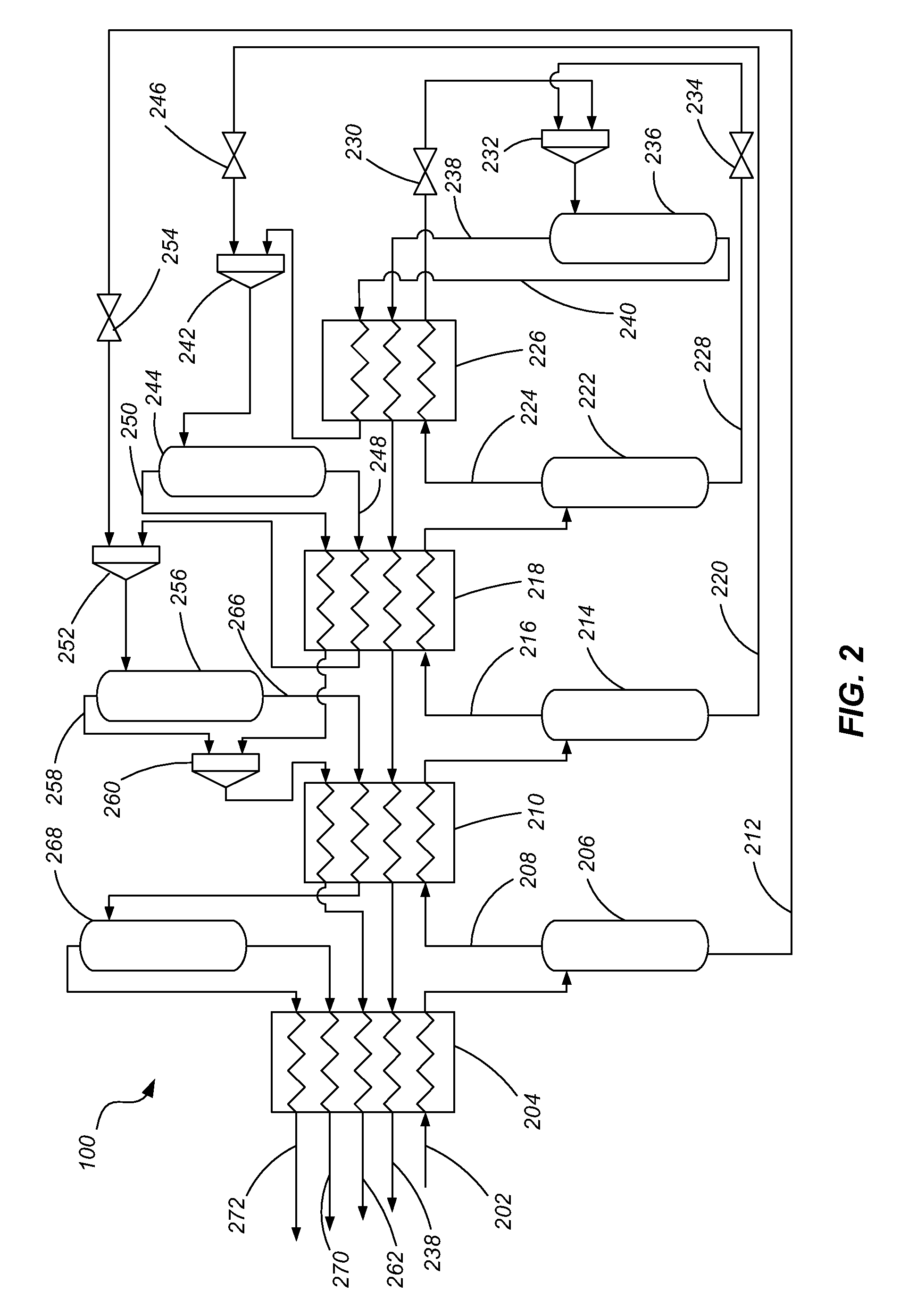

[0068]Modeling has been also been conducted for a separation plant such as described with respect to FIG. 2. As previously noted, the separation plant 200 described with respect to FIG. 2 includes an embodiment that employs a process of separation using both descending and ascending temperature methods of separation. In other words, one series of separation acts may be conducted such that each act occurs at a temperature that is colder than a previous separation act in the series while another series of separation acts is conducted such that each act of separation occurs at a temperature that is warmer than a previous act of separation in the series.

[0069]Referring to FIG. 2, conditions or “state points” of fluid flowing throughout the plant 200 are now described.

[0070]The feed stream 202 will include a mixed gas stream having numerous constituents including 0.0107 mass fraction of hydrogen, 0.2489 mass fraction of carbon monoxide, 0.2967 mass fraction of methane, 0.0896 mass fracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com