Inline processing and irradiation system

a technology of irradiation system and conveyor system, which is applied in the direction of transportation and packaging, instruments, and packaged goods types, can solve the problems of not being able to be placed into an inline manufacturing layout, the full system including the accelerator, radiation shielding and material handling conveyor system can be rather large, and the heating of packaged goods, etc., to achieve the effect of preserving the mechanical integrity of the device, reducing the power requirements of the process, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

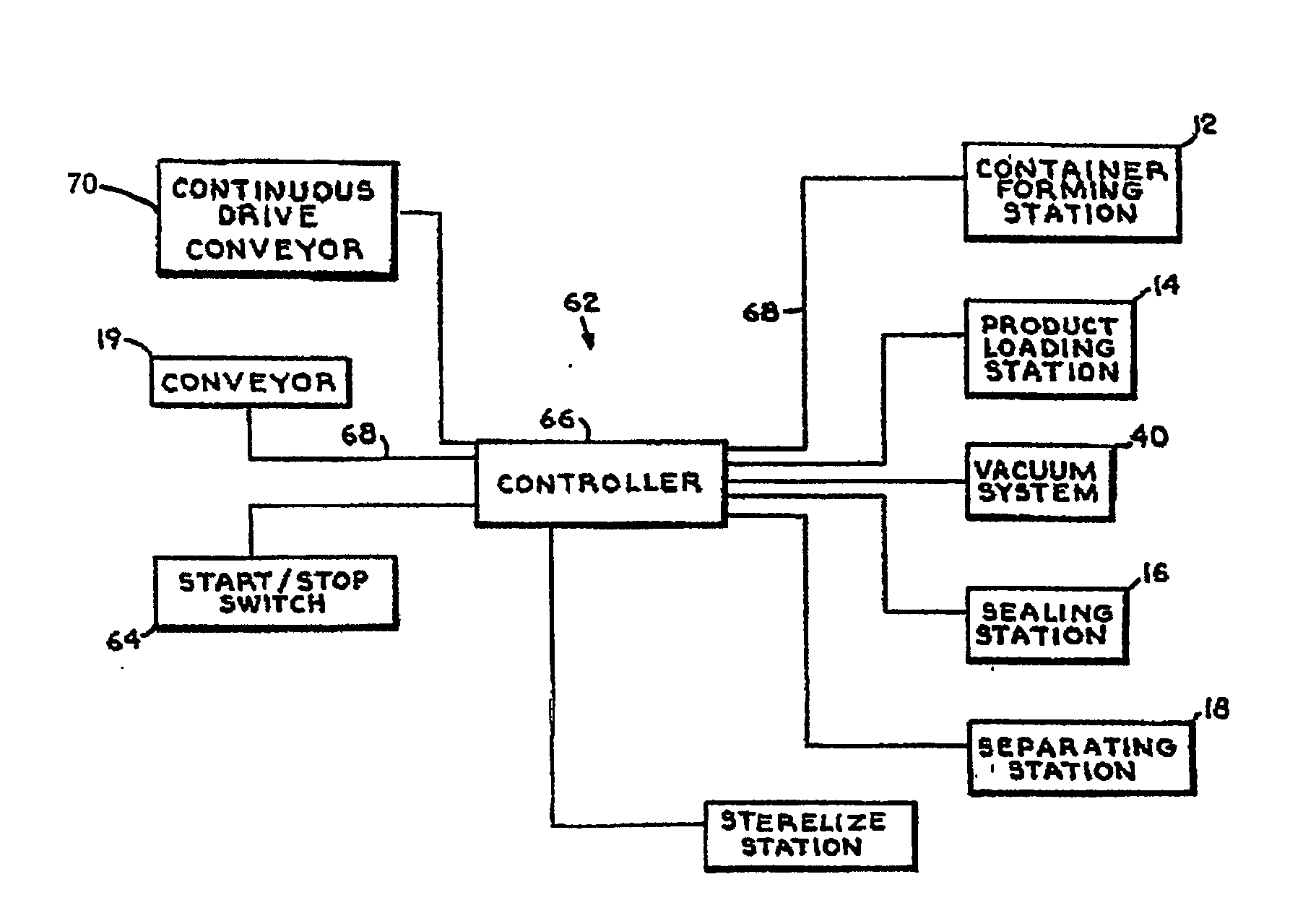

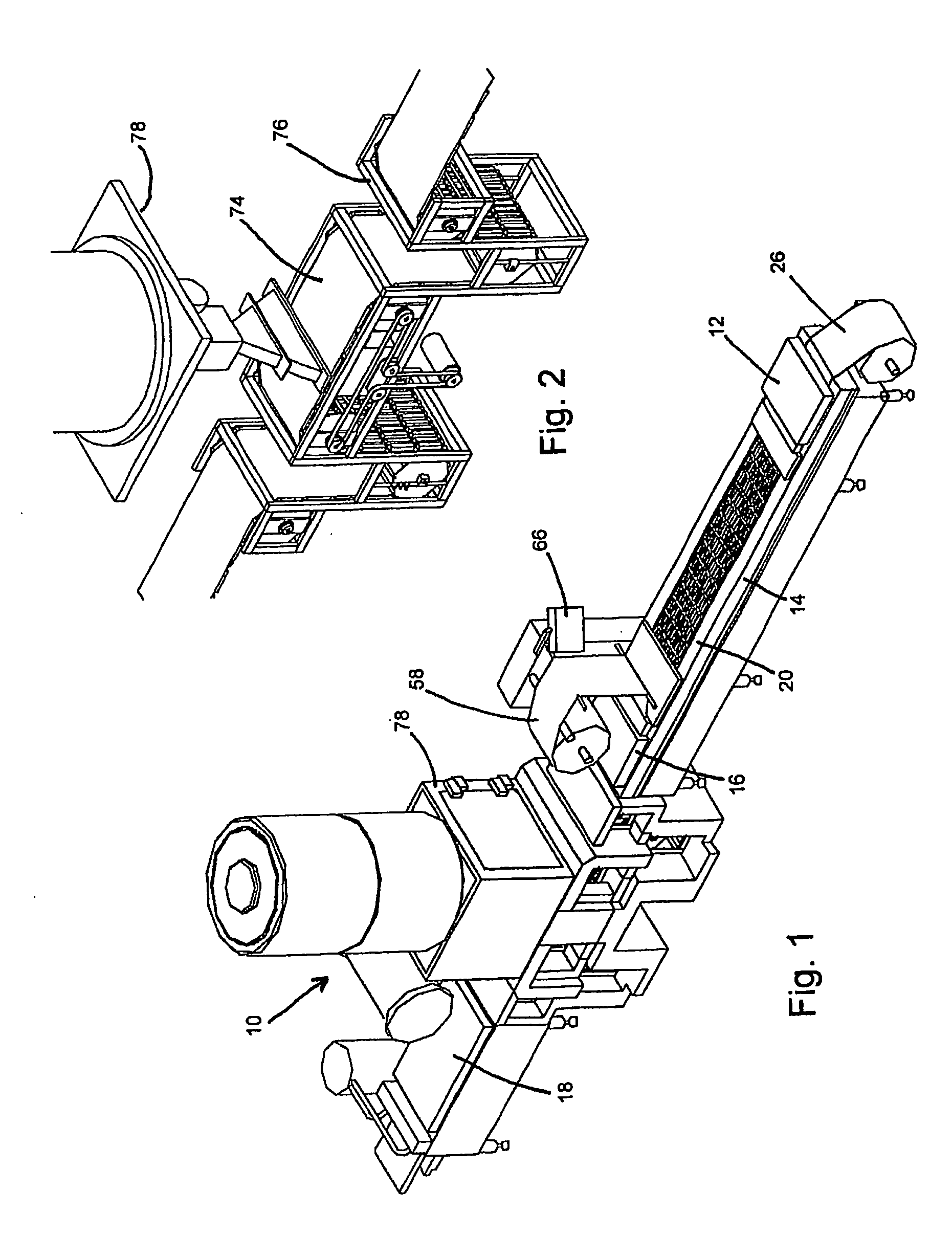

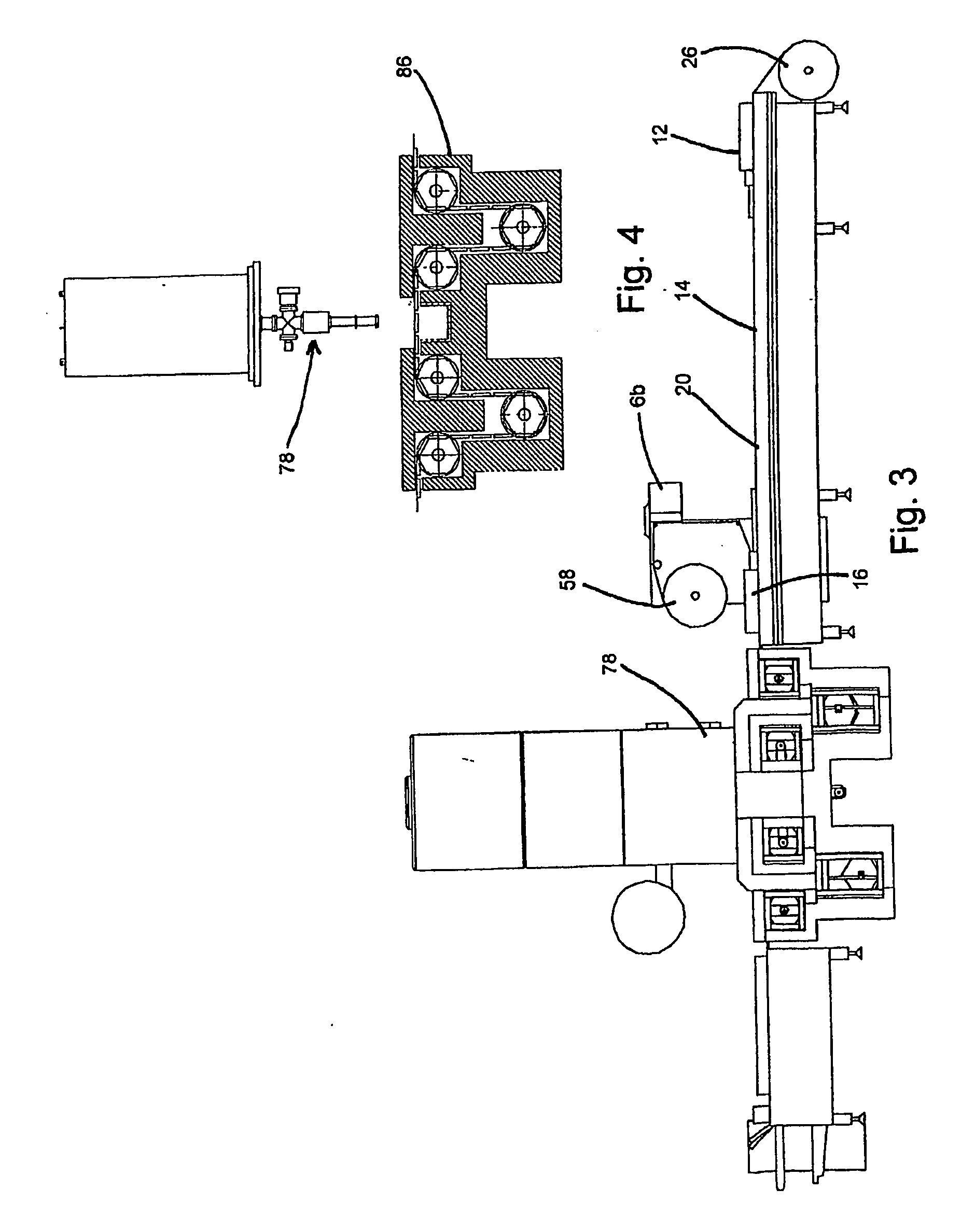

[0031]Referring to the accompanying drawings in which like reference numbers indicate like elements, FIGS. 1-4 illustrate the packaging machine 10 of the present invention according to a first embodiment. Machine 10 comprises a container forming station 12, a product loading station 14, a sealing station 16, a separating station 18 and a conveyor 20. It should be appreciated that while the present invention is described with reference to a packaging machine that can draw a vacuum, it is not necessarily limited to only those in-line form-fill-seal packaging machines with this vacuum capability. The present invention can be used with any type of in-line form-fill-seal packaging machine, including those which use a magazine to load packages onto a conveyor. Additionally, the packaging may be evacuated or be partially filled with an inert gas, air or some other medium or material, possibly even a liquid.

[0032]Conveyor 20 moves incrementally at spaced intervals 96 along the length of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| speed | aaaaa | aaaaa |

| beam current | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com