Carbon Nanohorn Carried Material And Process For Producing Carbon Nanotube

a carbon nanotube and horn technology, applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, metal/metal-oxide/metal-hydroxide catalyst, etc., can solve the problems of burden and difficulty in controlling and achieve the effect of easy collection and purification of carbon nanotube and control of the length of carbon nanotub

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0046]Graphite was subjected to CO2 laser ablation at room temperature in a stream of Ar (760 Torr) to prepare NHs in accordance with the method described in Chem. Phys. Lett., 1999, 309, 165. The obtained NHs were treated at 570 to 580° C. for 10 minutes in a stream of O2 to obtain carbon nanohorns (NHox) having openings in accordance with the method described in Mol. Pharm., 2005, 2, 475.

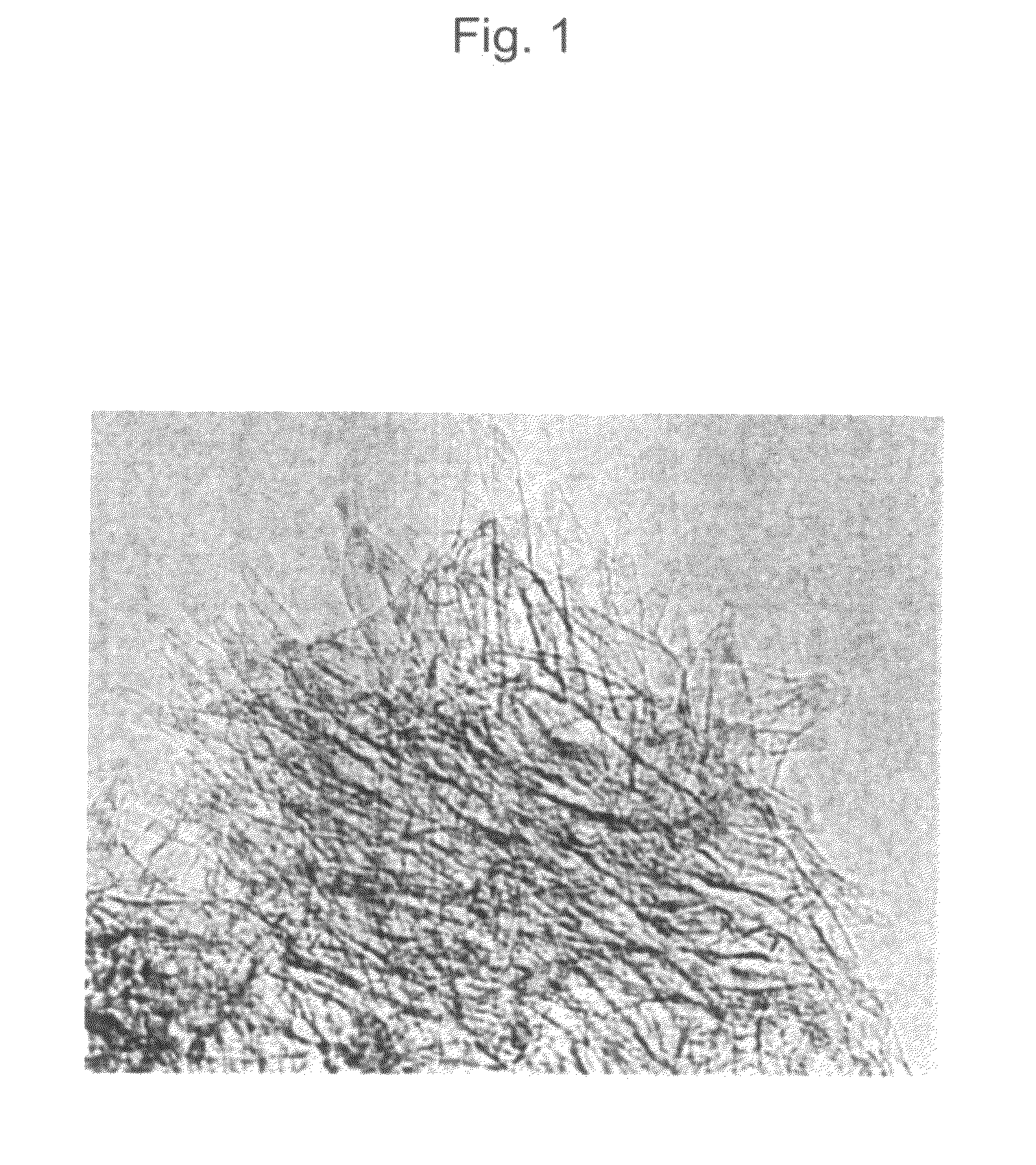

[0047]Next, 50 mg of iron acetate (manufactured by Sigma-Aldrich Inc.; purity: more than 99.995%) and 50 mg of the hole-opened nanohorns (NHox) were mixed with each other in 20 cm3 ethanol. The mixture was stirred at room temperature for 24 hours, filtered, washed with ethanol and dried to obtain iron acetate-carrying NHox having an iron content of 2 atomic %. The TEM photograph of the iron acetate-carrying NHox is shown in FIG. 1. The particles seen in NHox are those of the iron acetate.

[0048]The obtained iron acetate-carrying NHox was placed in a boat made of alumina and heated to 800° C. in a s...

example 2

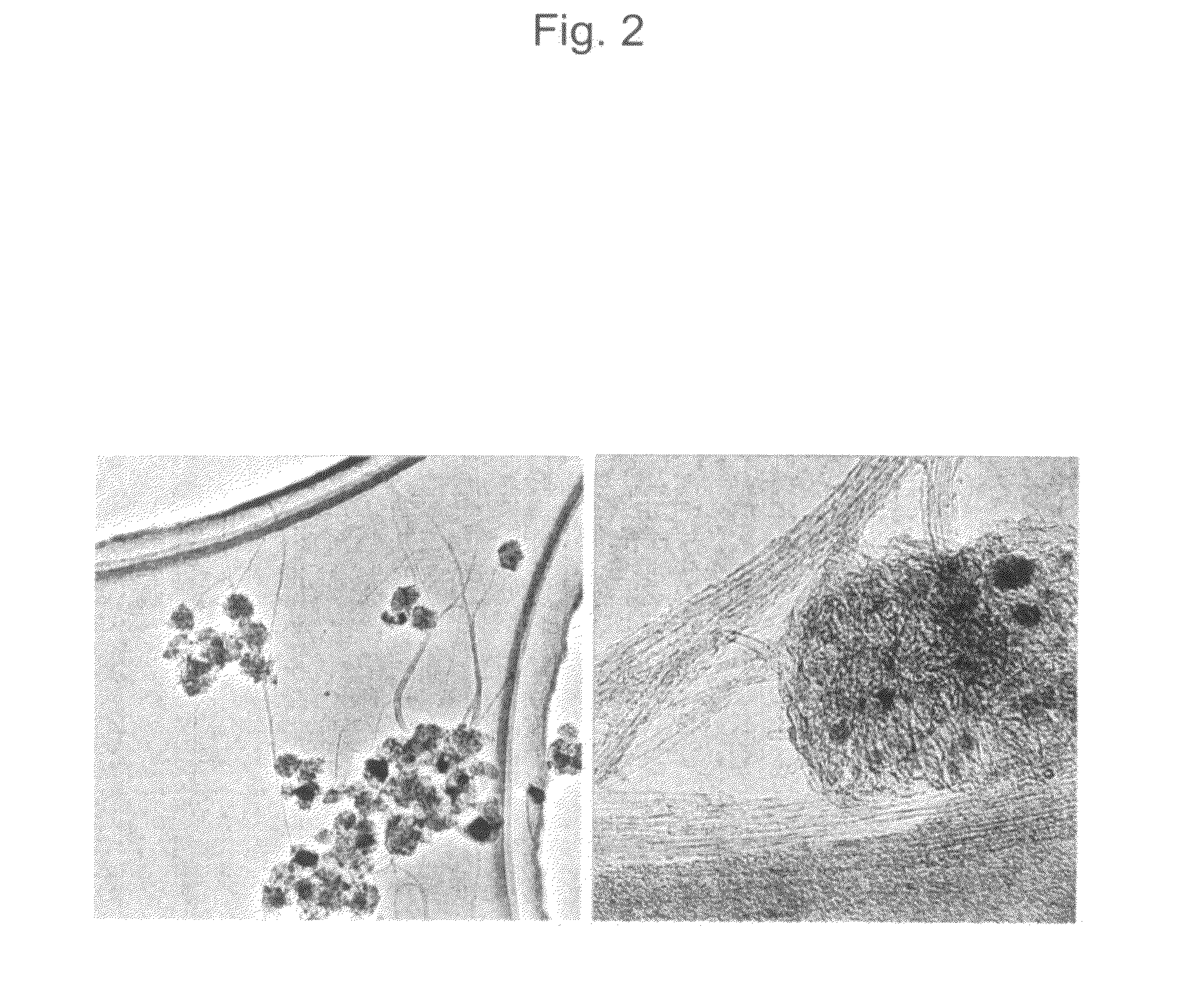

[0051]The experiment of Example 1 was conducted in the same manner as described except that nickel acetate was used in place of the iron acetate used in Example 1. The TEM photograph of the obtained multi-walled carbon nanotube (MWNT) is shown in FIG. 4. The TEM photograph of MWNT, obtained by CVD at 800° C. using carbon nanohorns containing therein nickel acetate, is seen in the observed image. In the right-side enlarged view, nickel oxide particles attached to MWNT are seen as black particles. The nickel oxide was formed by alteration of nickel acetate during the course of CVD.

example 3

[0052]The experiment of Example 1 was conducted in the same manner as described except that a mixture of cobalt acetate and molybdenum acetate (weight ratio: 1.1) was used in place of the iron acetate. The TEM photograph of the obtained double-walled carbon nanotube (DWNT) is shown in FIG. 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Vapor pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com