Nitride semiconductor device and power conversion apparatus including the same

a technology of nitride semiconductor and power conversion apparatus, which is applied in the direction of semiconductor devices, semiconductor/solid-state device details, electrical apparatus, etc., can solve the problems of increasing the power consumption of transistors, affecting the efficiency of nitride semiconductor transistors, and difficult to provide nitride semiconductor transistors with low electric loss in off-action for high-power applications, so as to achieve less electric loss, less leakage current, and less electric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

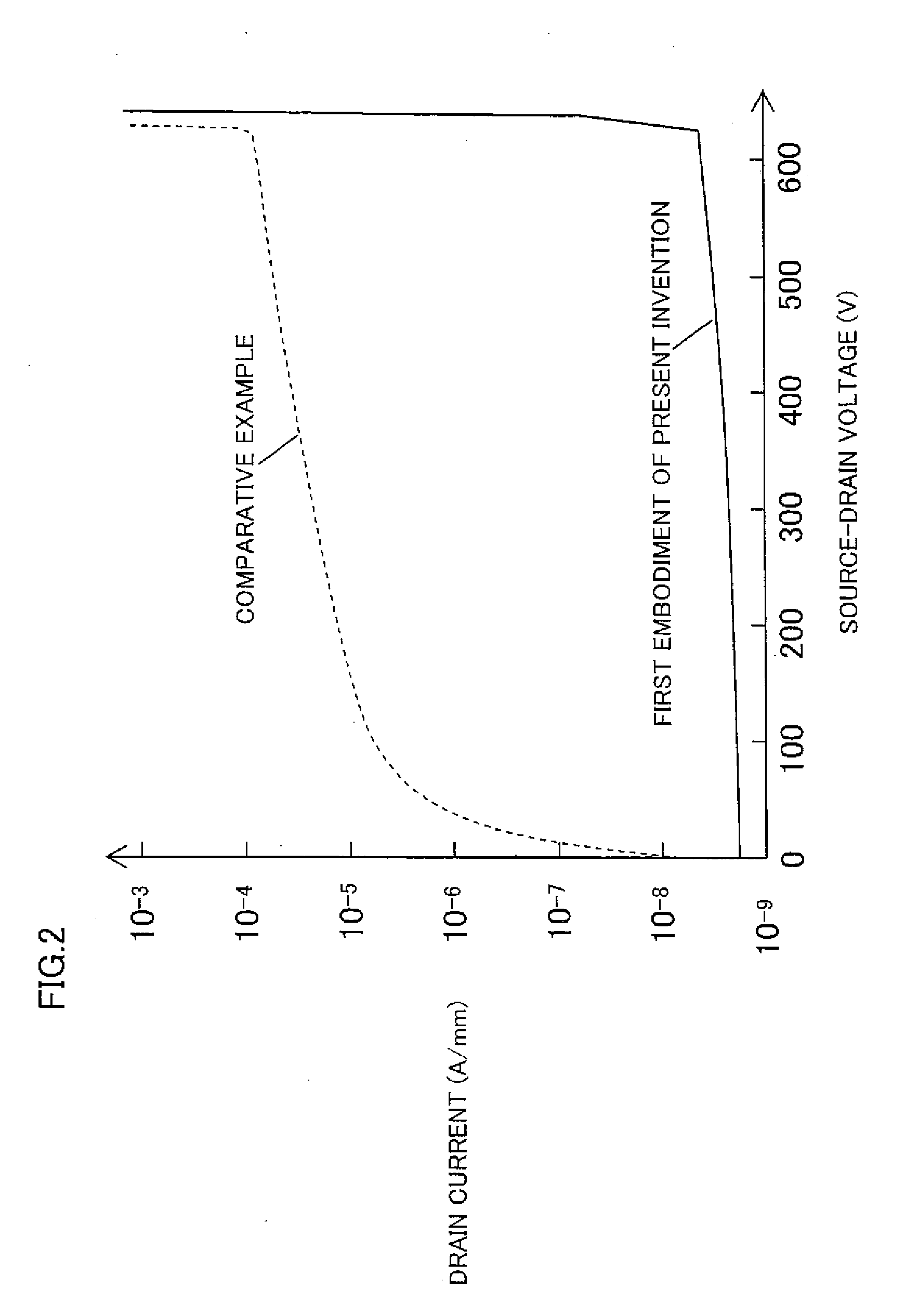

first embodiment

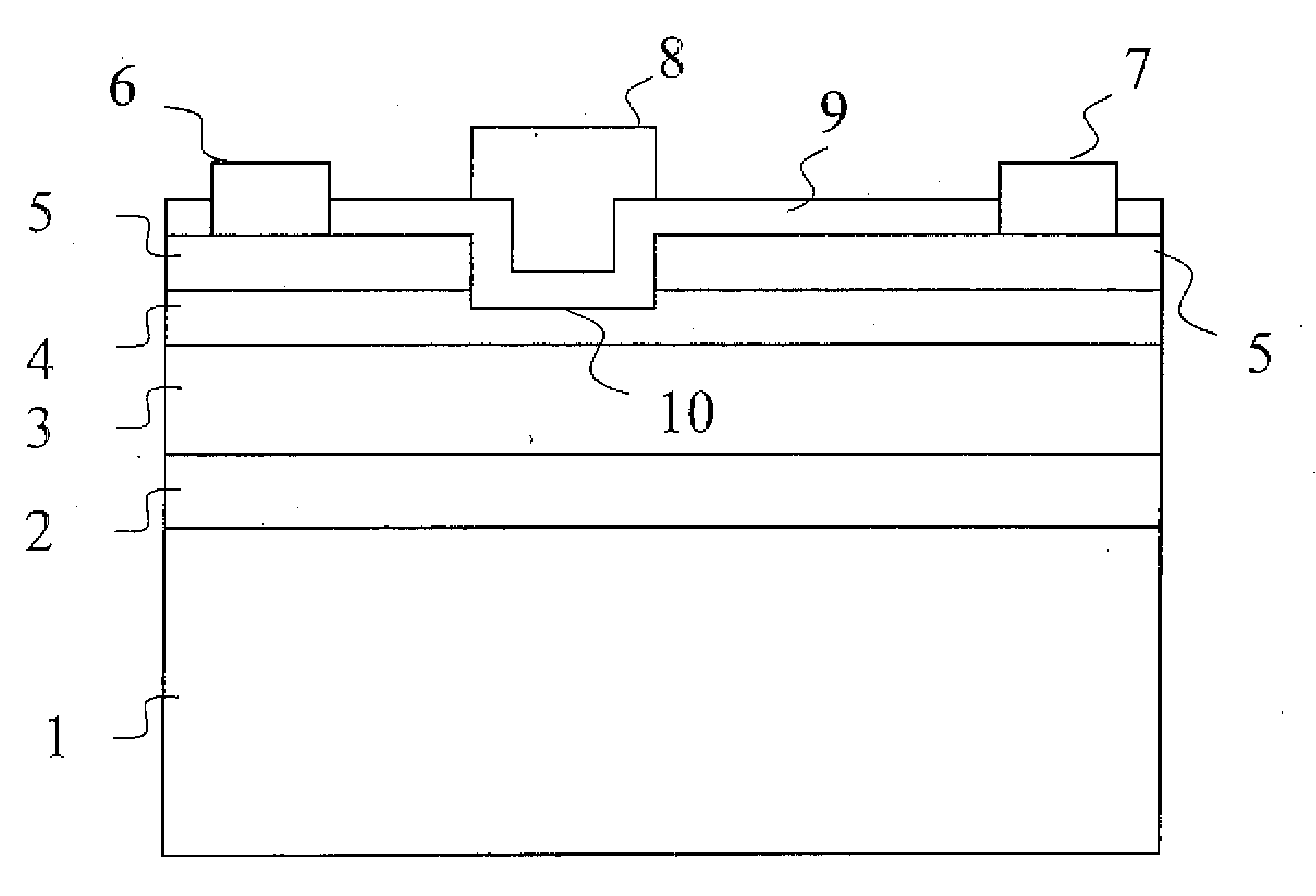

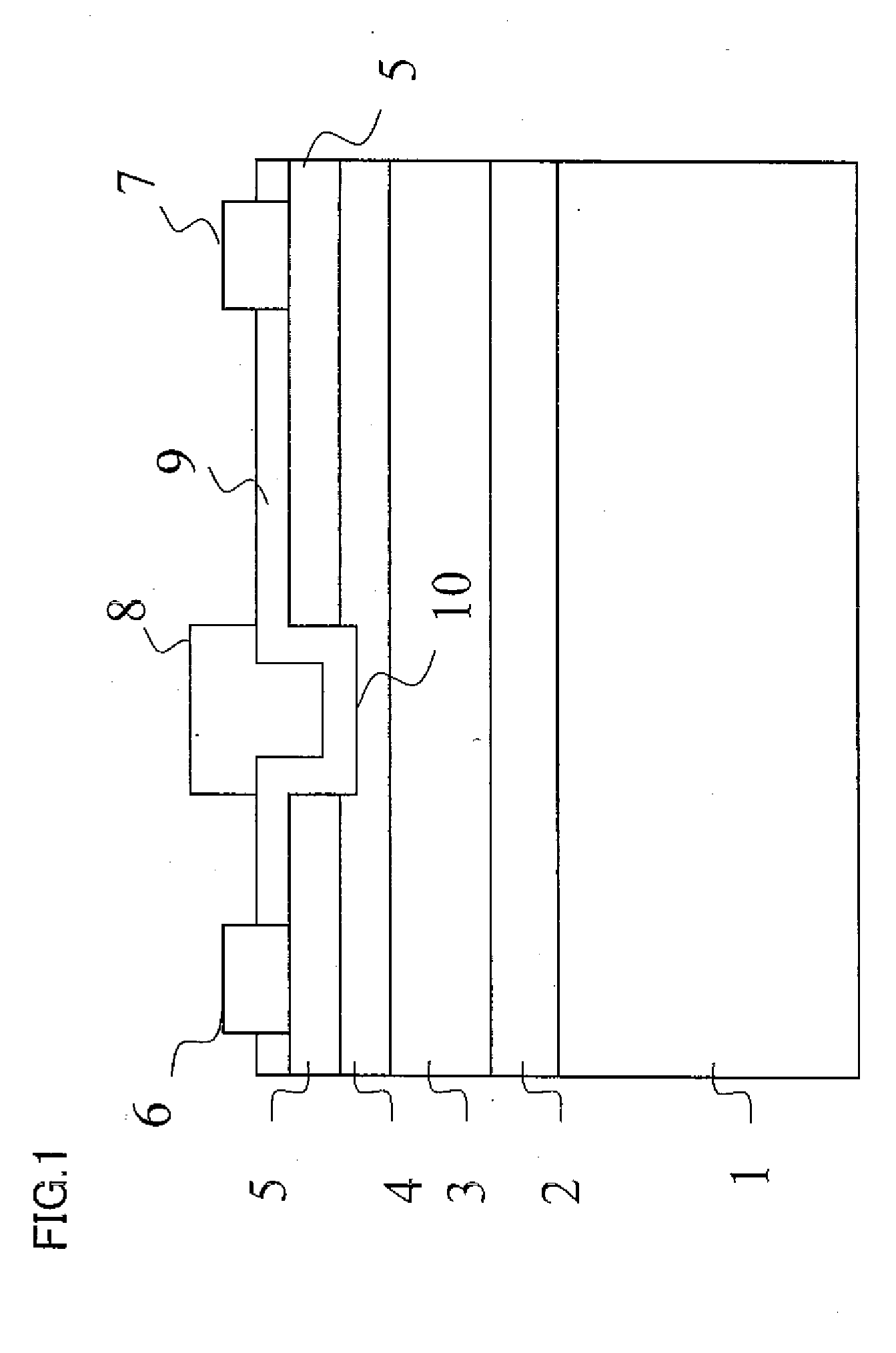

[0031]FIG. 1 shows a schematic cross-sectional view illustrating a nitride semiconductor device of a first embodiment according to the present invention. It should be noted that, in the drawings of the present application, the like reference numerals represent the like components or corresponding components. Further, in the drawings of the present application, dimensional relation between length, width, thickness, and such does not represent actual dimensional relation and is arbitrarily modified for the sake of clarity and simplicity of the drawings.

[0032]The field-effect transistor shown in FIG. 1 includes a substrate 1, a buffer layer 2, a first nitride semiconductor layer 3, a second nitride semiconductor layer 4 as a carrier travel layer, a third nitride semiconductor layer 5 as a barrier layer having a wide band gap compared to second nitride semiconductor layer 4, a source electrode 6, a drain electrode 7, a gate electrode 8, a dielectric film 9, and a recess structure 10.

[00...

second embodiment

[0050]FIG. 6 is a schematic cross-sectional view illustrating a nitride semiconductor device of a second embodiment according to the present invention. The field-effect transistor of FIG. 6 is different from the transistor of FIG. 5 in that first nitride semiconductor layer 3 of p-type GaN is replaced with a first nitride semiconductor layer 13 of p-type InGaN. That is, first nitride semiconductor layer 13 has a narrower band gap as compared with buffer layer 2.

[0051]More specifically, first nitride semiconductor layer 13 is made of p-type In0.1Ga0.9N doped with Mg at a concentration of 1×1019 cm−3, and has a thickness of 50 nm. Further, second nitride semiconductor layer 4 made of undoped GaN is 200 nm thick. First nitride semiconductor layer 13, second nitride semiconductor layer 4, and third nitride semiconductor layer 5 are lattice-matched with a GaN layer as a top layer included in buffer layer 2. Recess area 10 is dug down to a depth of 150 nm from the heterojunction interface...

third embodiment

[0060]FIG. 8 is a schematic cross-sectional view illustrating a nitride semiconductor device of a third embodiment according to the present invention. The field-effect transistor of FIG. 8 is different from the transistor of FIG. 5 in that first nitride semiconductor layer 3 of p-type GaN is replaced with a first nitride semiconductor layer 23 of AlGaN. That is, first nitride semiconductor layer 23 has a wider band gap as compared with the top layer of buffer layer 2 and second nitride semiconductor layer 4.

[0061]More specifically, first nitride semiconductor layer 23 is made of undoped Al0.05Ga0.95N, and has a thickness of 500 nm. Further, second nitride semiconductor layer 4 of undoped GaN is set to be 40 nm thick. Recess area 10 is dug down to a depth of 30 nm from the heterojunction interface between third nitride semiconductor layer 5 and second nitride semiconductor layer 4.

[0062]First nitride semiconductor layer 23 is not limited to AlGaN, and as long as a material having a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com