A kind of manufacturing method of semiconductor discharge tube

A manufacturing method and technology for discharge tubes, which are applied in semiconductor/solid-state device manufacturing, semiconductor devices, circuits, etc., can solve problems such as increasing production costs, affecting the quality of discharge tubes, stacking faults, etc., and achieving the effect of reducing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Perform primary oxidation on both sides of the silicon wafer at the same time to form a primary oxide layer.

[0031] (2) Perform photolithography on the deep boron region of the primary oxide layer of the silicon wafer.

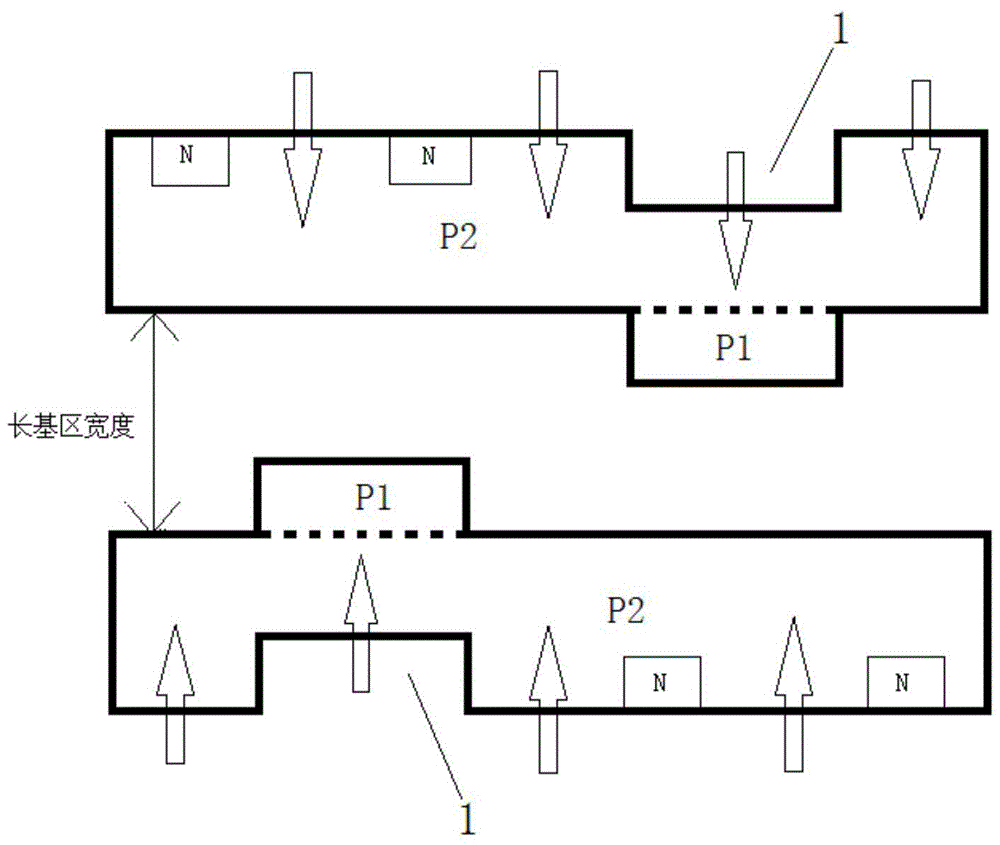

[0032] (3) Etch the surface position of the silicon wafer where the deep boron region is to be formed by using a silicon etching solution, and form a 60 μm deep groove 1 by etching, and the groove 1 corresponds to the shape of the deep boron region, such as figure 1 shown.

[0033] (4) Perform photolithography on the base region of the silicon wafer.

[0034] (5) Carry out light boron diffusion at 1000° C., and the diffusion time is 100 minutes. At the same diffusion rate, the diffusion direction is as figure 1 As shown by the middle arrow, due to the existence of groove 1 formed by corrosion, the junction depth of boron diffusion in groove 1 will be greater than that of boron diffusion in other parts, forming a protrusion (the protrusion dista...

Embodiment 2

[0044] (1) Perform primary oxidation on both sides of the silicon wafer at the same time to form a primary oxide layer.

[0045] (2) Perform photolithography on the deep boron region of the primary oxide layer of the silicon wafer.

[0046] (3) Etch the surface position of the silicon wafer where the deep boron region is to be formed by using a silicon etching solution, and form a 55 μm deep groove by etching, and the groove corresponds to the shape of the deep boron region, such as figure 1 shown.

[0047] (4) Perform photolithography on the base region of the silicon wafer.

[0048] (5) Carry out light boron diffusion at 950° C., and the diffusion time is 60 minutes. At the same diffusion rate, the diffusion direction is as figure 1 As shown by the middle arrow, due to the existence of the groove formed by corrosion, the junction depth of boron diffusion in the groove will be larger than that of the boron diffusion area in other parts, forming a protruding (protruding dis...

Embodiment 3

[0058] (1) Perform primary oxidation on both sides of the silicon wafer at the same time to form a primary oxide layer.

[0059] (2) Perform photolithography on the deep boron region of the primary oxide layer of the silicon wafer.

[0060] (3) Etch the surface position of the silicon wafer where the deep boron region is to be formed by using a silicon etching solution, and form a 45 μm deep groove by etching, and the groove corresponds to the shape of the deep boron region, such as figure 1 shown.

[0061] (4) Perform photolithography on the base region of the silicon wafer.

[0062] (5) Carry out light boron diffusion at 1050° C., and the diffusion time is 90 minutes. At the same diffusion rate, the diffusion direction is as figure 1 As shown by the middle arrow, due to the existence of the groove formed by corrosion, the junction depth of boron diffusion in the groove will be greater than that of the boron diffusion area in other parts, forming a protruding (protruding d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com