Process for the selective hydrodesulfurization of a gasoline feedstock containing high levels of olefins

a technology of olefins and hydrodesulfurization, which is applied in the petroleum industry, hydrocarbon oil refining, and refining to eliminate heteroatoms. it can achieve the effects of high selectivity, low phosphorus content, and high hydrodesulfurization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

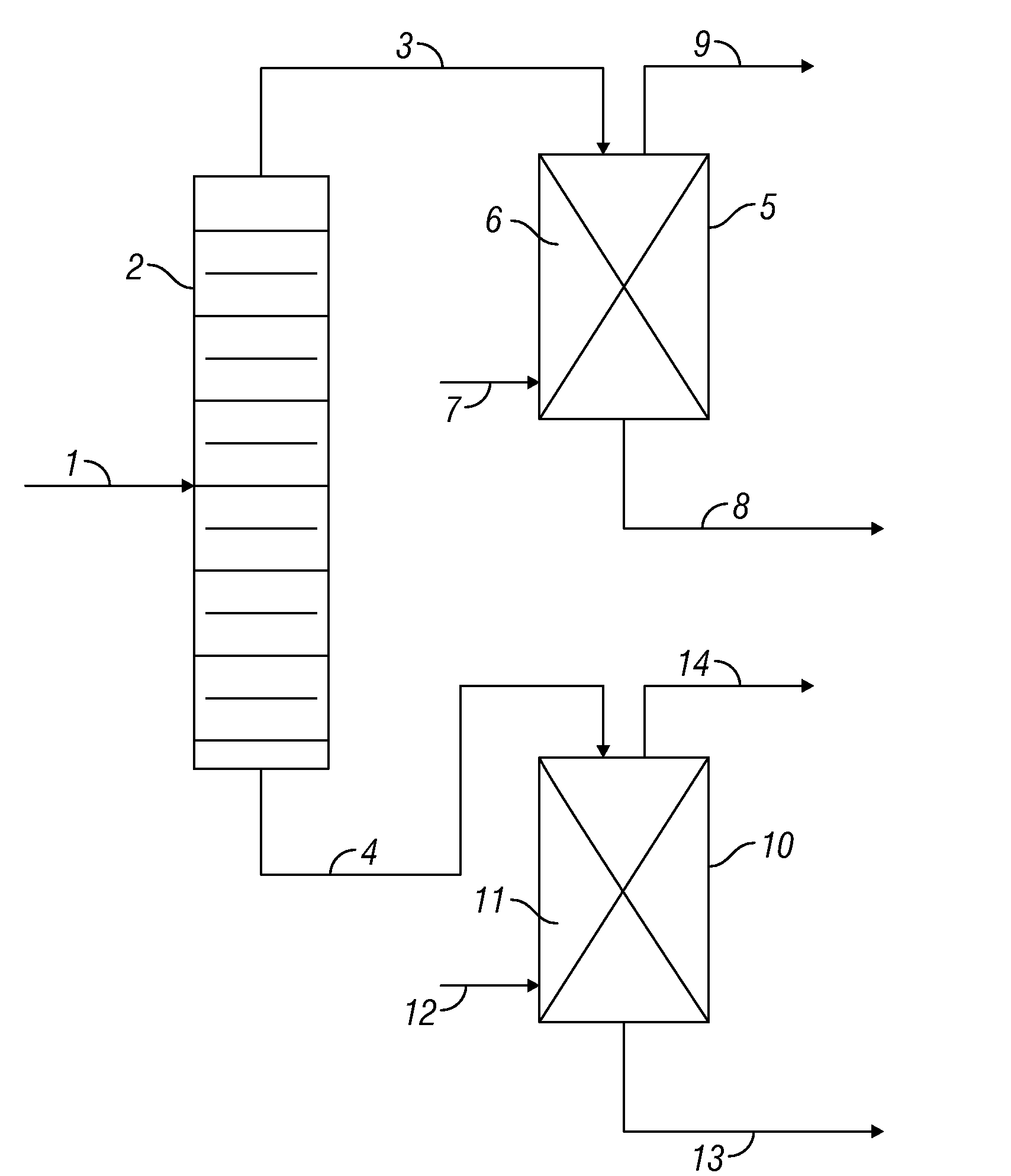

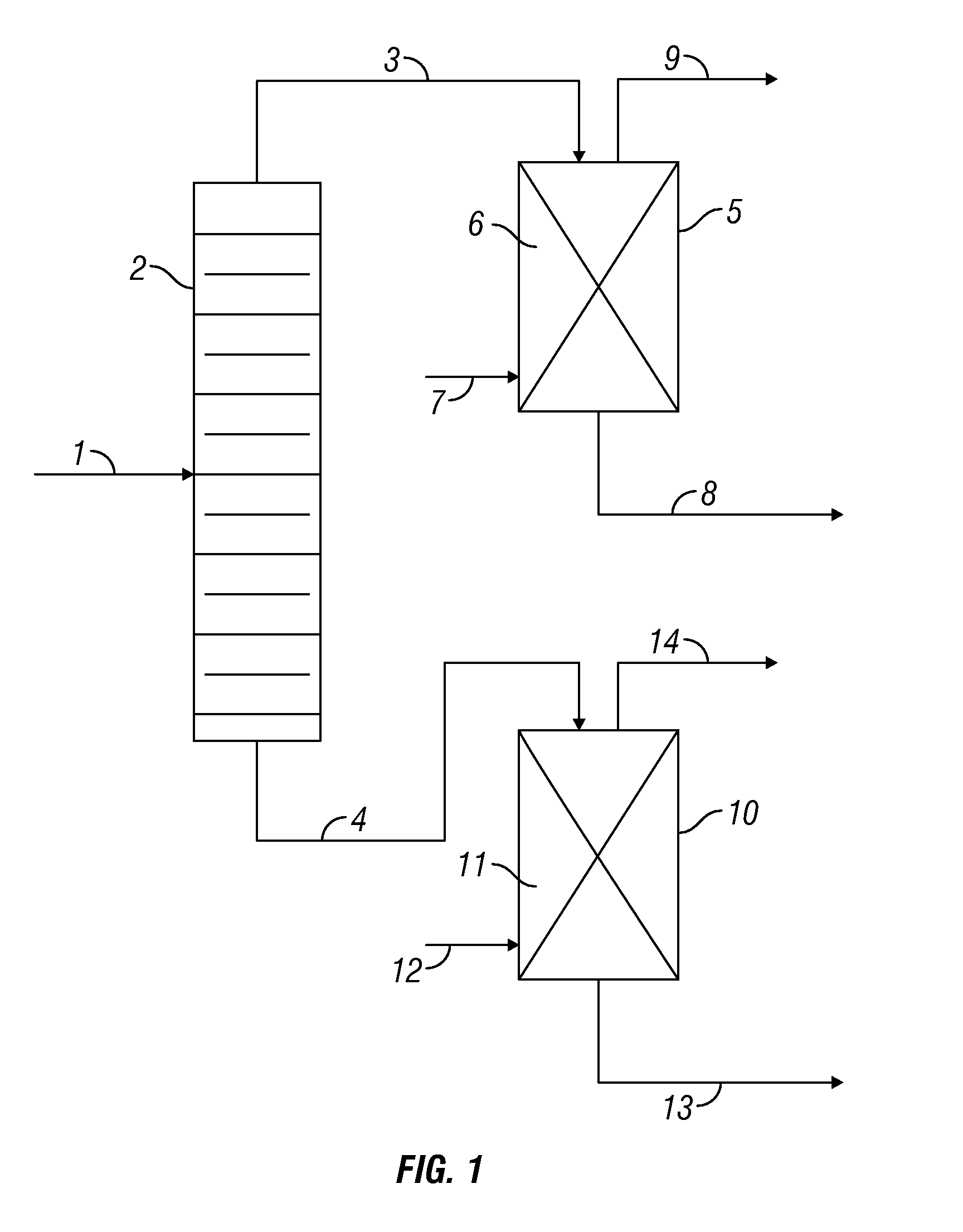

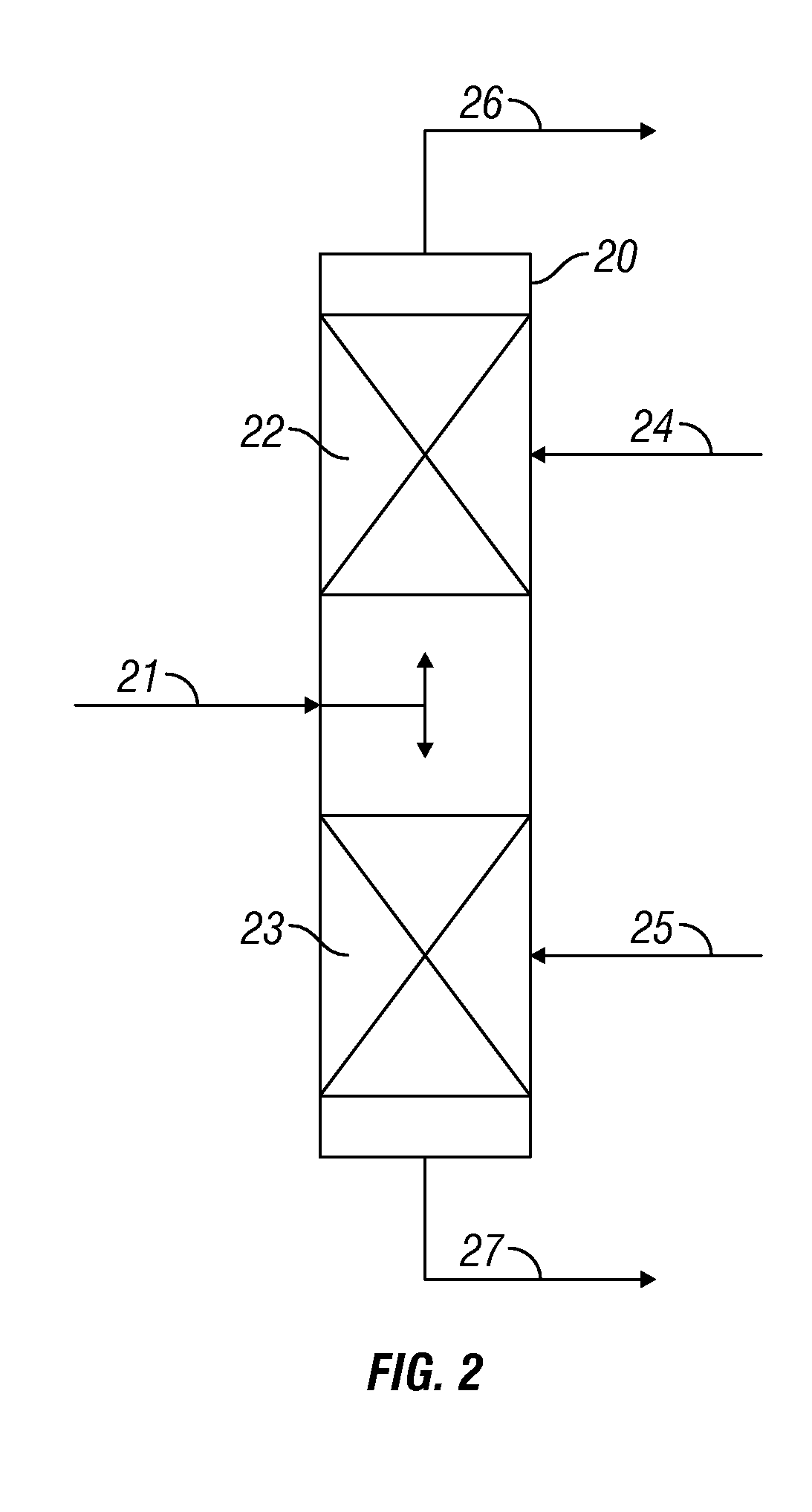

Image

Examples

example i

[0103]This Example describes the preparation of Catalyst A, which is a high activity catalyst suitable for use in the various embodiments of the inventive process. Also described in this example is a comparison catalyst, which is a commercially available catalyst, that was compared to Catalyst A in the selective hydrodesulfurization experiments described in Example II.

Catalyst A

[0104]In accordance with the invention, Catalyst A was prepared from an alumina support having a relatively high surface of at least 280 m2 / g, and which contained a low concentration of silica. The support for Catalyst A was prepared using a commercially available silica-alumina powder material, which contained 2 wt % silica with the remaining balance being substantially entirely alumina. The powder was mixed with deionized water in an amount to provide an approximate loss on ignition for the mixture of around 64 wt %. Also added to the mixture was approximately 1 wt % of a 69.8% nitric acid solution and appr...

example ii

[0107]This Example summarizes the experiment used to measure the performance of Catalyst A and the comparison catalyst in the selective hydrodesulfurization of an olefin-containing hydrocarbon feedstock having a concentration of sulfur.

[0108]The testing was performed using high throughput nanoreactors. Approximately 1 ml of crushed catalyst was used in each reactor. The feed to the reactors was a synthetically prepared gasoline feedstock that included a range of hydrocarbon components that are typically found in cracked gasoline (e.g., heptane, hexane, octane, octane, butylenes, and toluene), and it was spiked with organic nitrogen and sulfur compounds to provide concentrations thereof. The reactors were operated under suitable selective hydrodesulfurization temperature, pressure and space velocity process conditions.

[0109]Summaries of the results from the aforedescribed testing are presented for illustrative purposes in the comparative plots presented in FIG. 3 and FIG. 4.

[0110]FIG...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore diameter | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com