Heat-accumulating heater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

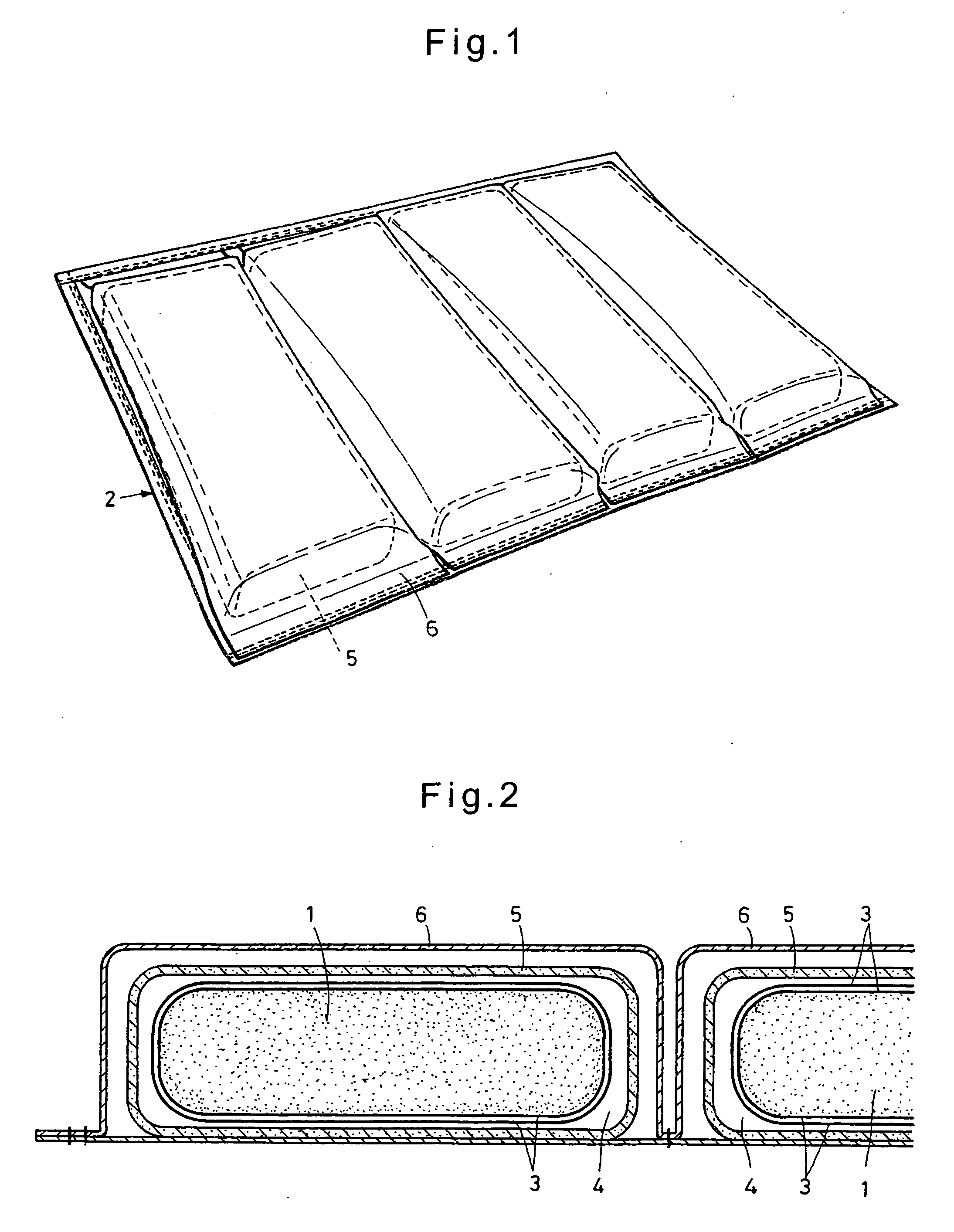

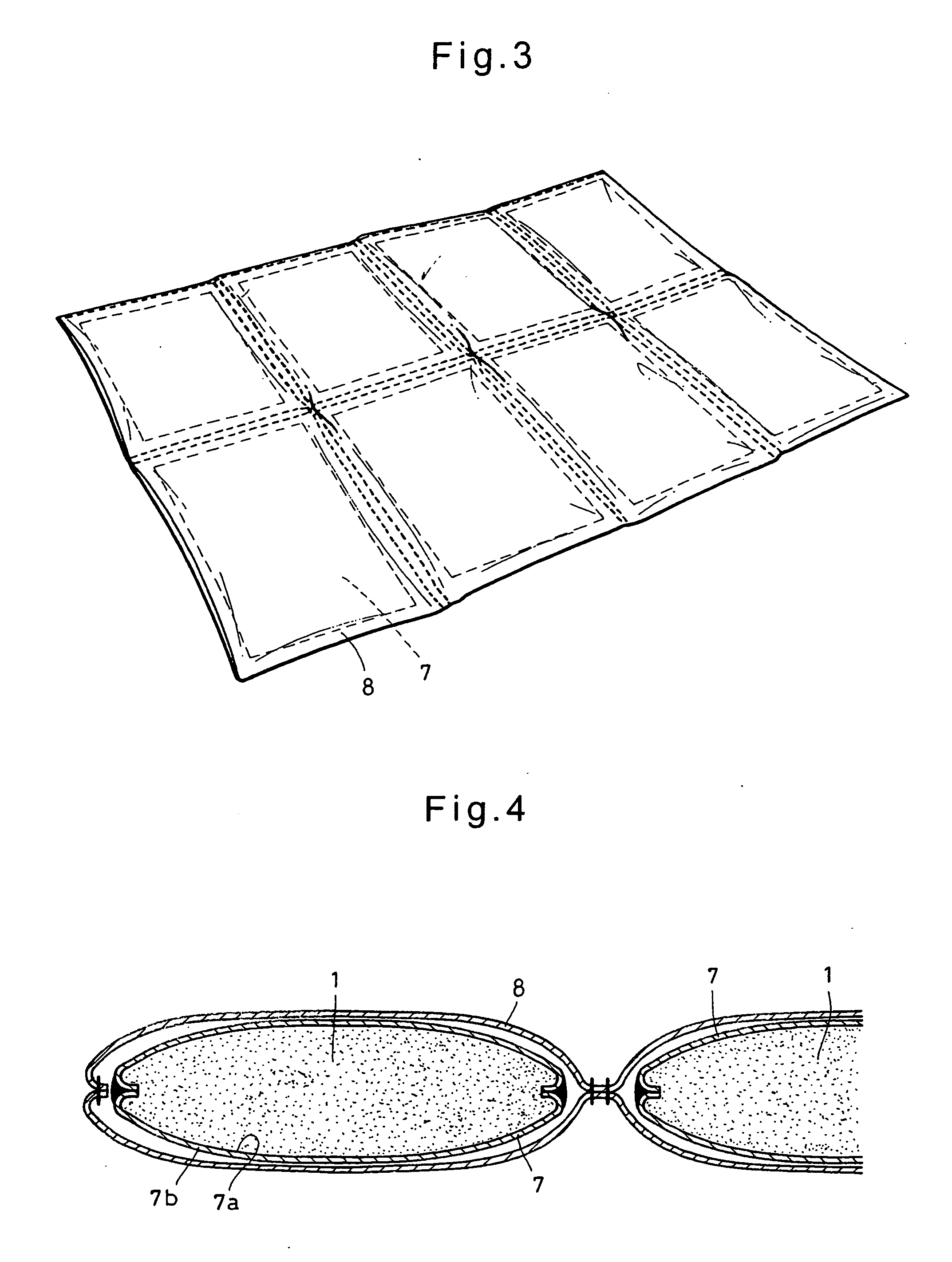

[0067]This example is a heat-accumulating heater of the same type as the first embodiment. In this example, as the powdery latent heat storage substance, powder was used comprising porous silicon oxide impregnated with 60% of a heat-accumulating substance of which the major component is phase-changing n-paraffin having a melting point of 70° C. (Nopos made by Yamaichi Co., Ltd.).

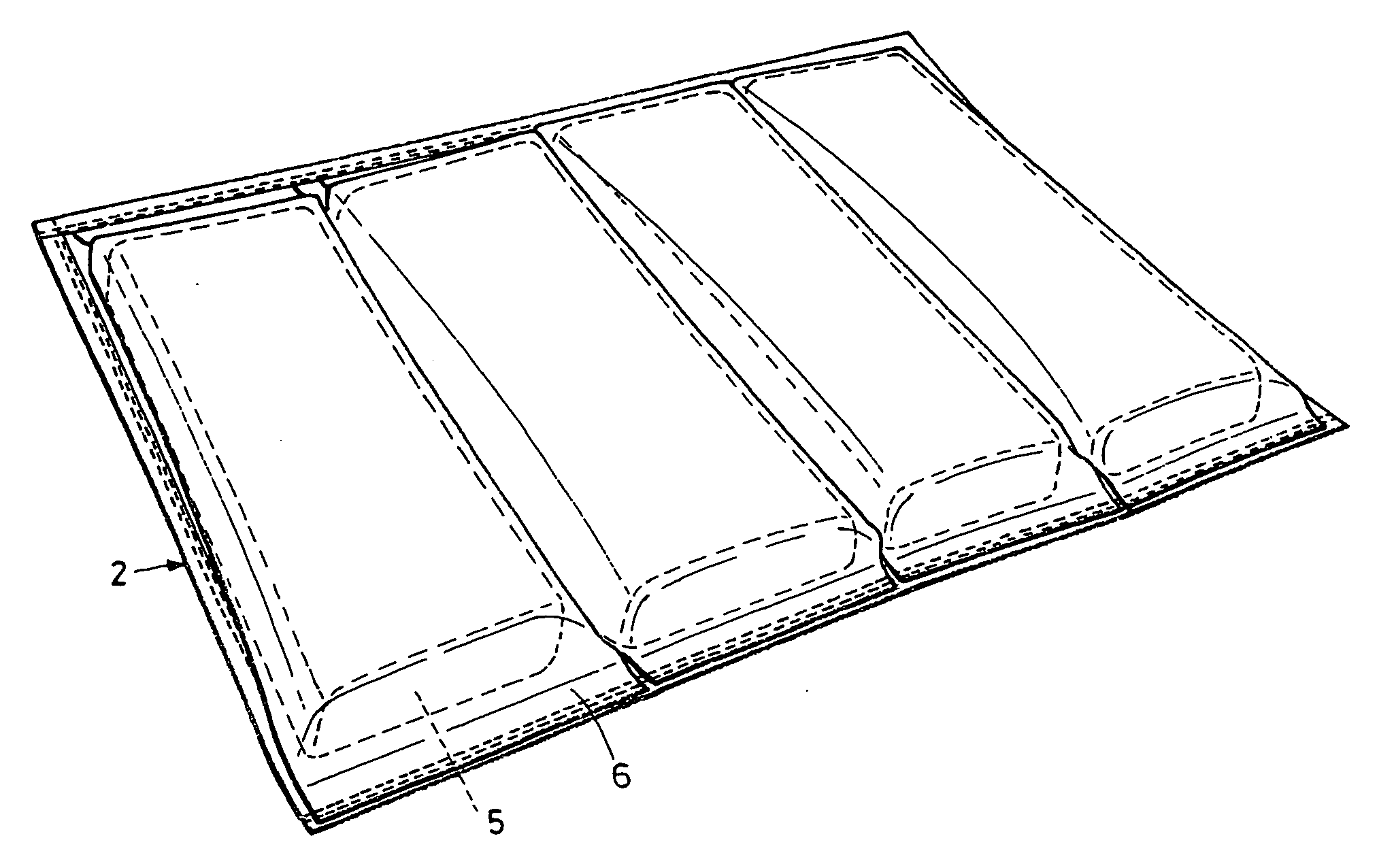

[0068]The heat-accumulating heater of this example comprises four inner container members each formed of a nylon film bag and a polyethylene film bag that are superposed one on the other, four first outer container members which are in the form of rubber packs and in which the inner container members are received, respectively, and a pack made of a nylon fabric in which the first outer container members are held.

[0069]The heat-accumulating heater thus obtained measured 37 cm long, 29 cm wide and 3 cm high, had a volume of 3219 ml, and weighed 1500 g in total including 800 g of powdery paraffinic latent heat ...

example 2

[0070]This example is a heat-accumulating heater of the same type as the first embodiment. In this example, as the powdery latent heat storage substance, powder was used comprising porous silicon oxide impregnated with 60% of a heat-accumulating substance of which the major component is phase-changing n-paraffin having a melting point of 70° C. (Nopos made by Yamaichi Co., Ltd.).

[0071]The heat-accumulating heater of this example comprises four inner container members each formed of an aluminum coating film bag formed with holes having a diameter of about 0.2 μm and a nylon film bag that are superposed one on the other, four first outer container members which are in the form of rubber packs and in which the inner container members are received, respectively, and a pack made of a nylon fabric in which the first outer container members are held.

[0072]The heat-accumulating heater thus obtained measured 37 cm long, 29 cm wide and 3 cm high, had a volume of 3219 ml, and weighed 850 g in ...

example 3

[0073]This example is a heat-accumulating heater of the same type as the first embodiment. In this example, as the powdery latent heat storage substance, cellulose beads are used having a diameter of 5 mm and impregnated with a heat-accumulating substance of which the major component is phase-changing n-paraffin having a melting point of 70° C.

[0074]The heat-accumulating heater of this example comprises four inner container members each formed of an aluminum coating film bag formed with holes having a diameter of about 0.2 μm and a nylon film bag that are superposed one on the other, four first outer container members which are in the form of rubber packs and in which the inner container members are received, respectively, and a pack made of a nylon fabric in which the first outer container members are held.

[0075]The heat-accumulating heater thus obtained measured 37 cm long, 29 cm wide and 3 cm high, had a volume of 3219 ml, and weighed 650 g in total including 600 g of powdery par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com