Track Bed Structures

a technology of track bed and structure, applied in the direction of track superstructure, temporary paving, ways, etc., can solve the problems of track bed failure, detrimental effect on functional properties, slurry formed by silt and clay suspended, etc., to provide structural stability and inhibit passage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

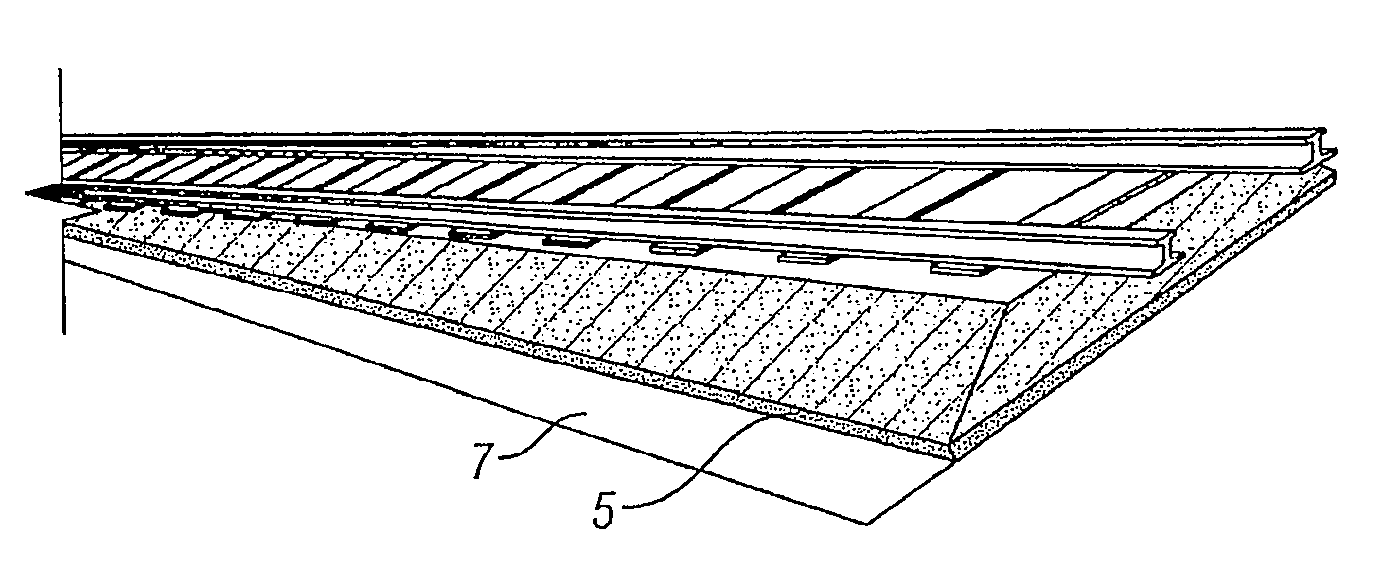

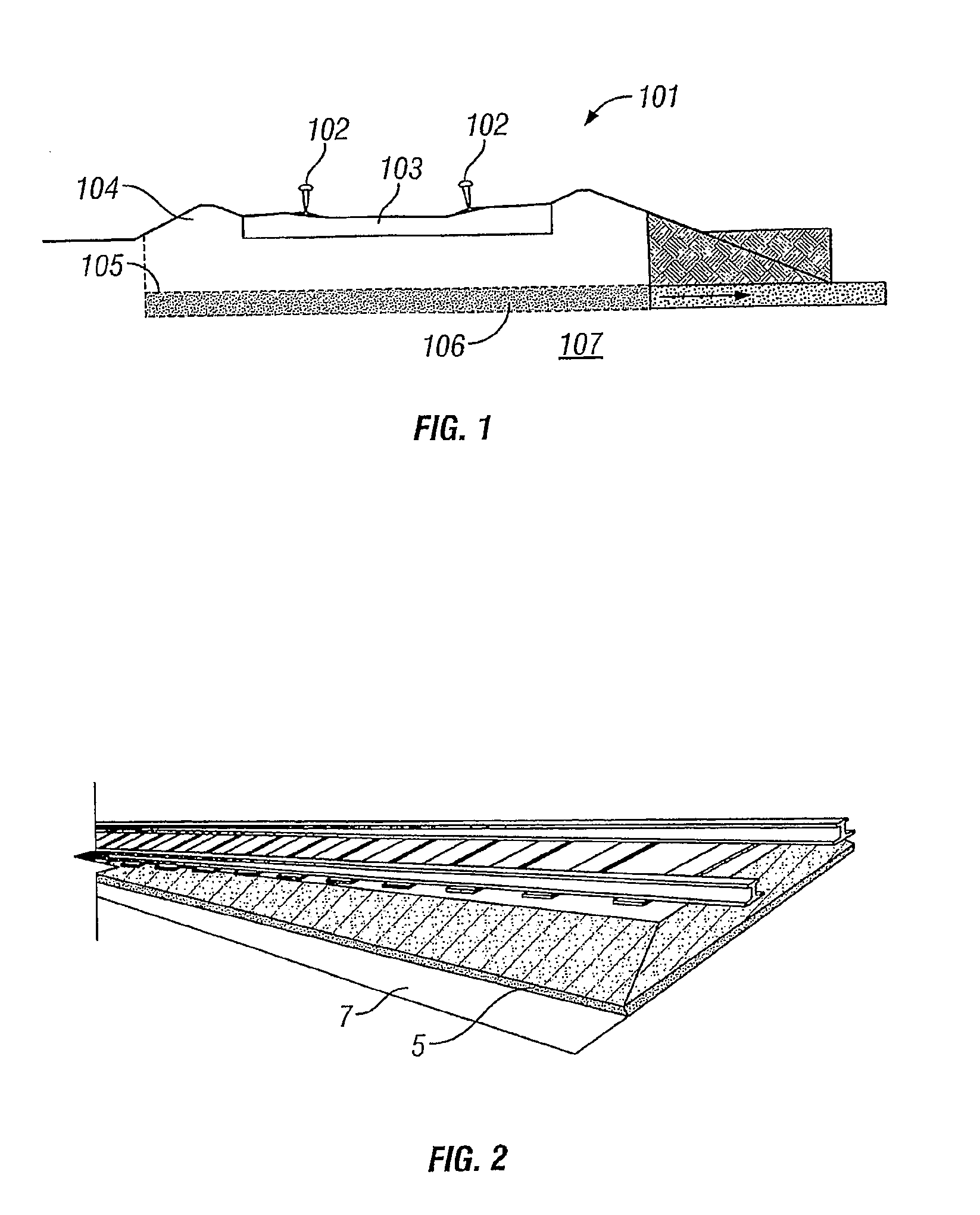

[0050]Referring to the drawings and in particular FIG. 2, there is shown a track bed similar to that shown in FIG. 1, but in which a structural element 5 of the present invention is positioned below the ballast 4 but above the sub-grade fine soil or mudrock layer 7.

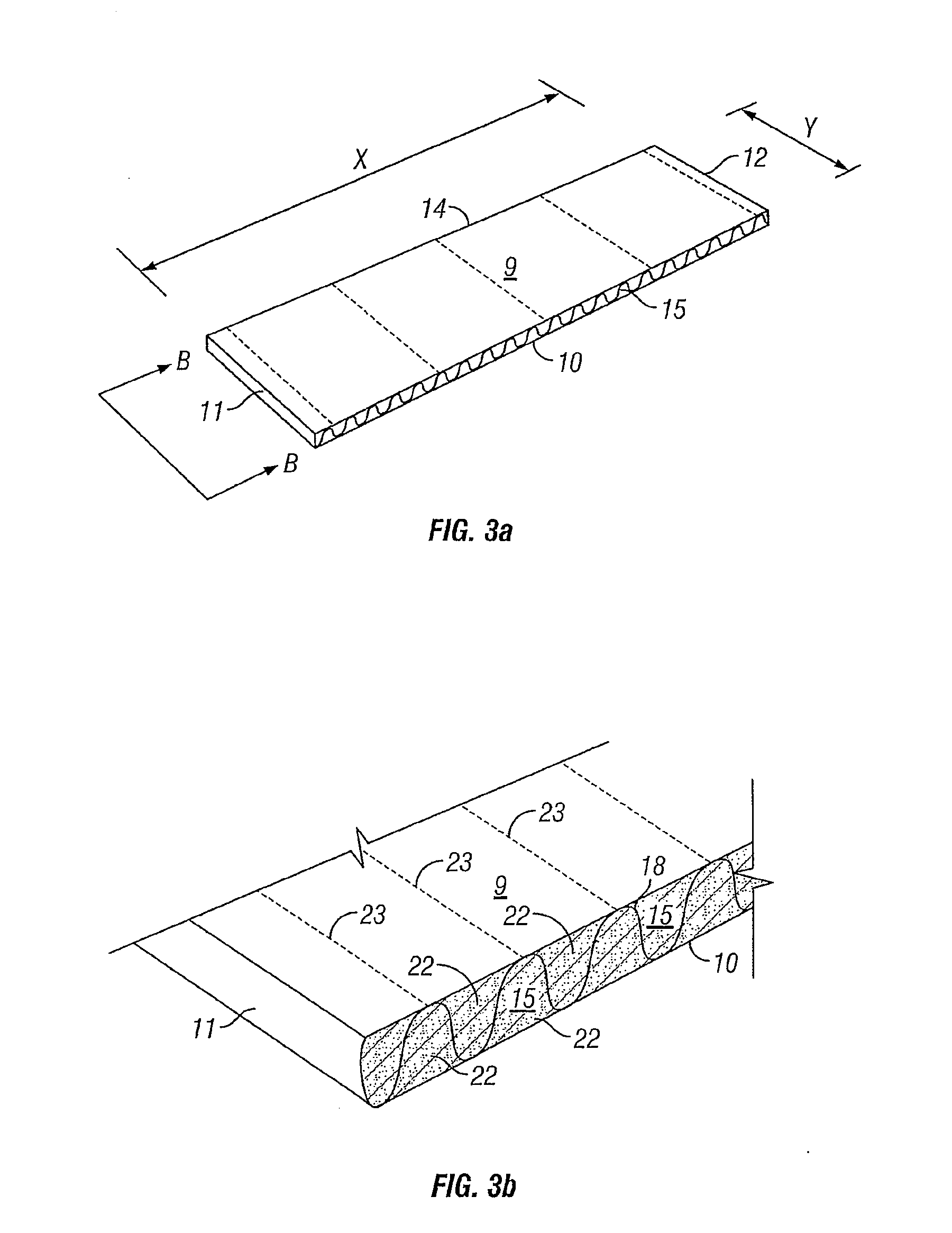

[0051]As shown in FIGS. 3A to 3C, the track bed structural element 5 comprises a an elongate structural envelope 5 having an upper liquid permeable surface 9 of geo-textile material, a lower liquid permeable surface 10, which may be identical to the upper surface or different in terms of material, thickness, permeability or other physical properties. The longitudinally opposed ends 11,12 of the structural envelope 5 are closed by end panels, which may be permeable and of geo-textile material. Longitudinally running edges 14, 15 of the structural envelope are also closed, but shown open in FIGS. 3A to 3C for explanatory purposes. A bulk filler filter material 15 is contained or encapsulated internally of the structural env...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com