Molding apparatus

a technology of molding apparatus and cylinder head, which is applied in the direction of presses, magnetic bodies, manufacturing tools, etc., can solve the problems of inability to achieve improvement in magnetic properties and inability to obtain high orientation, and achieve the effect of high orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

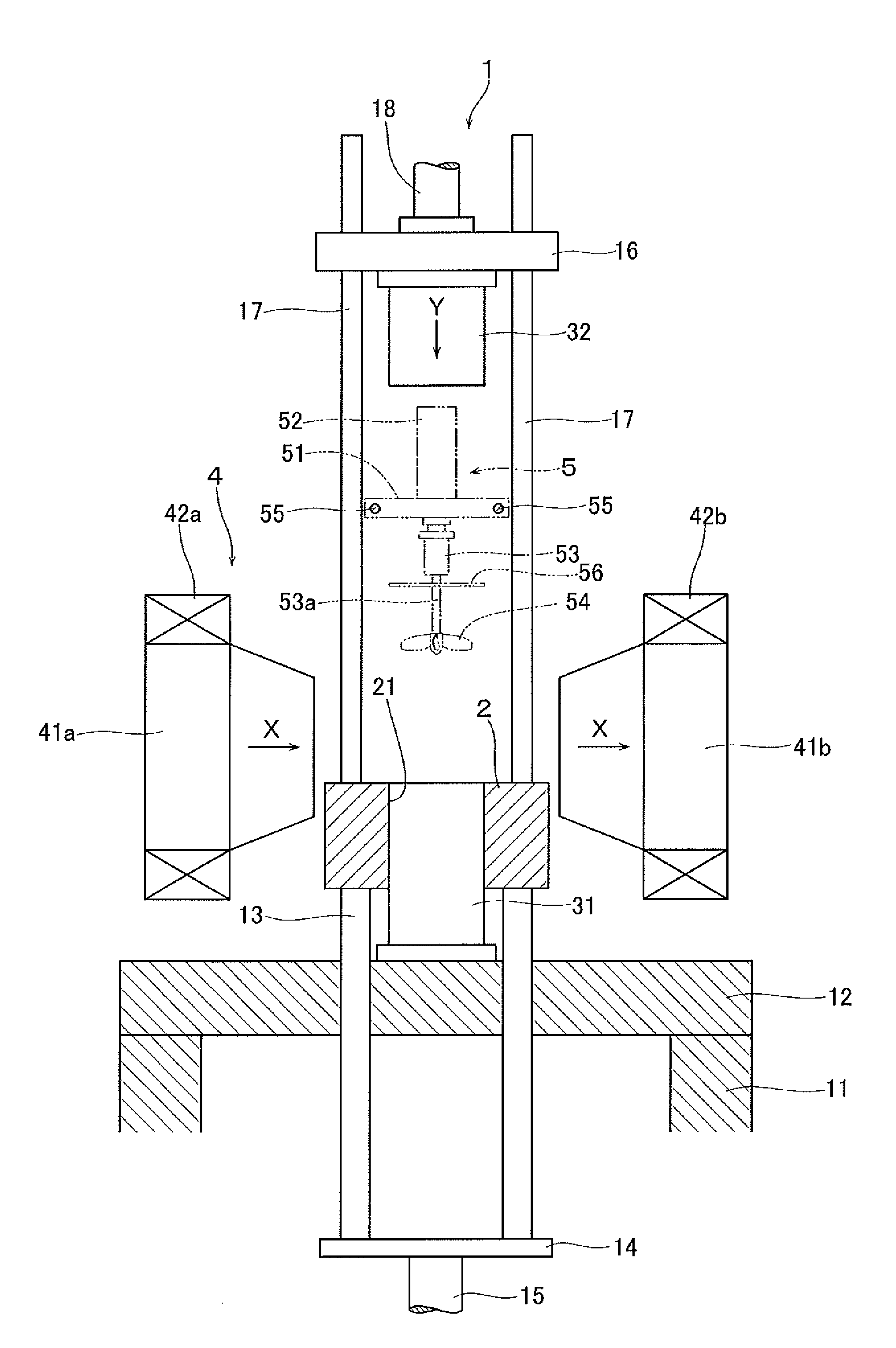

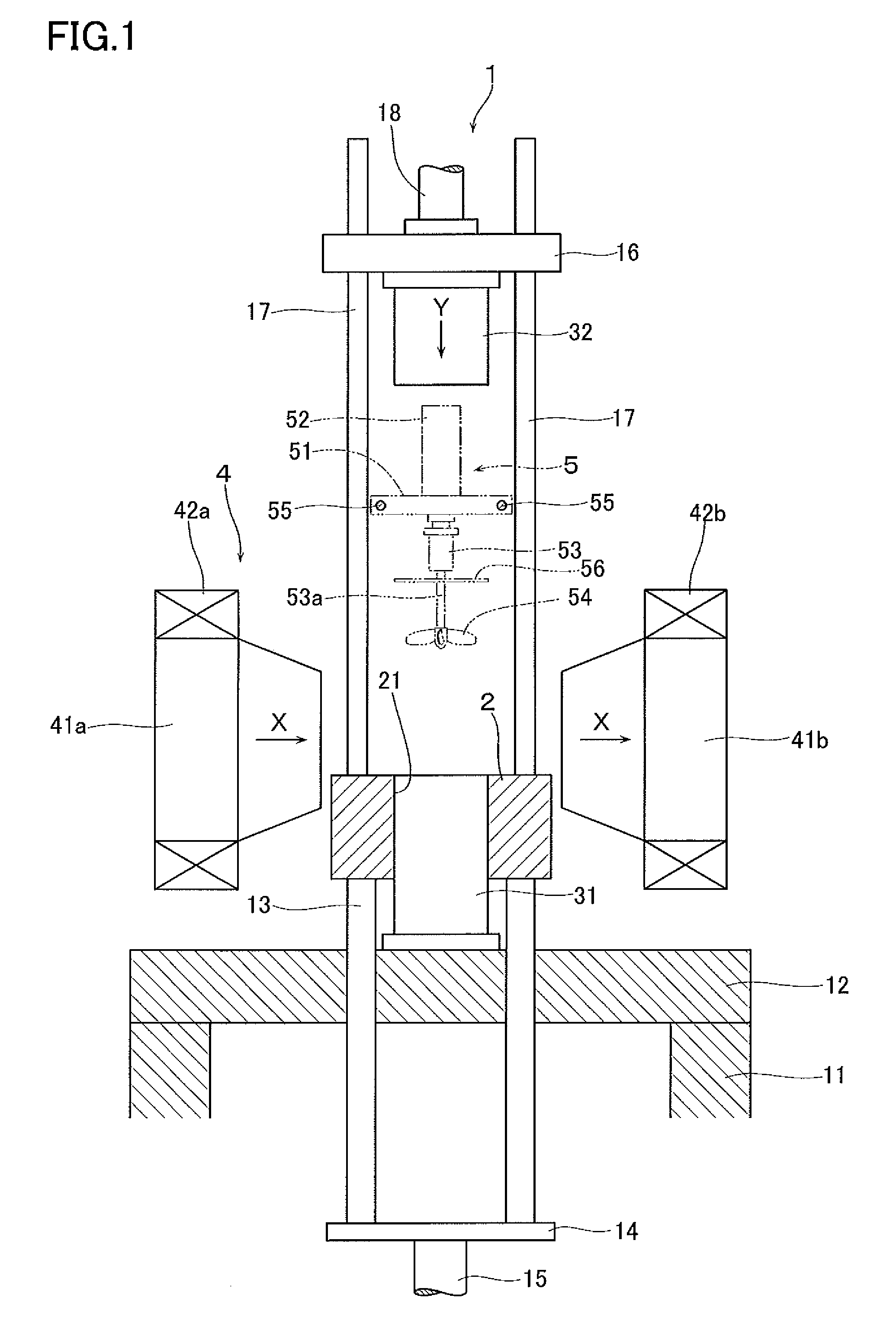

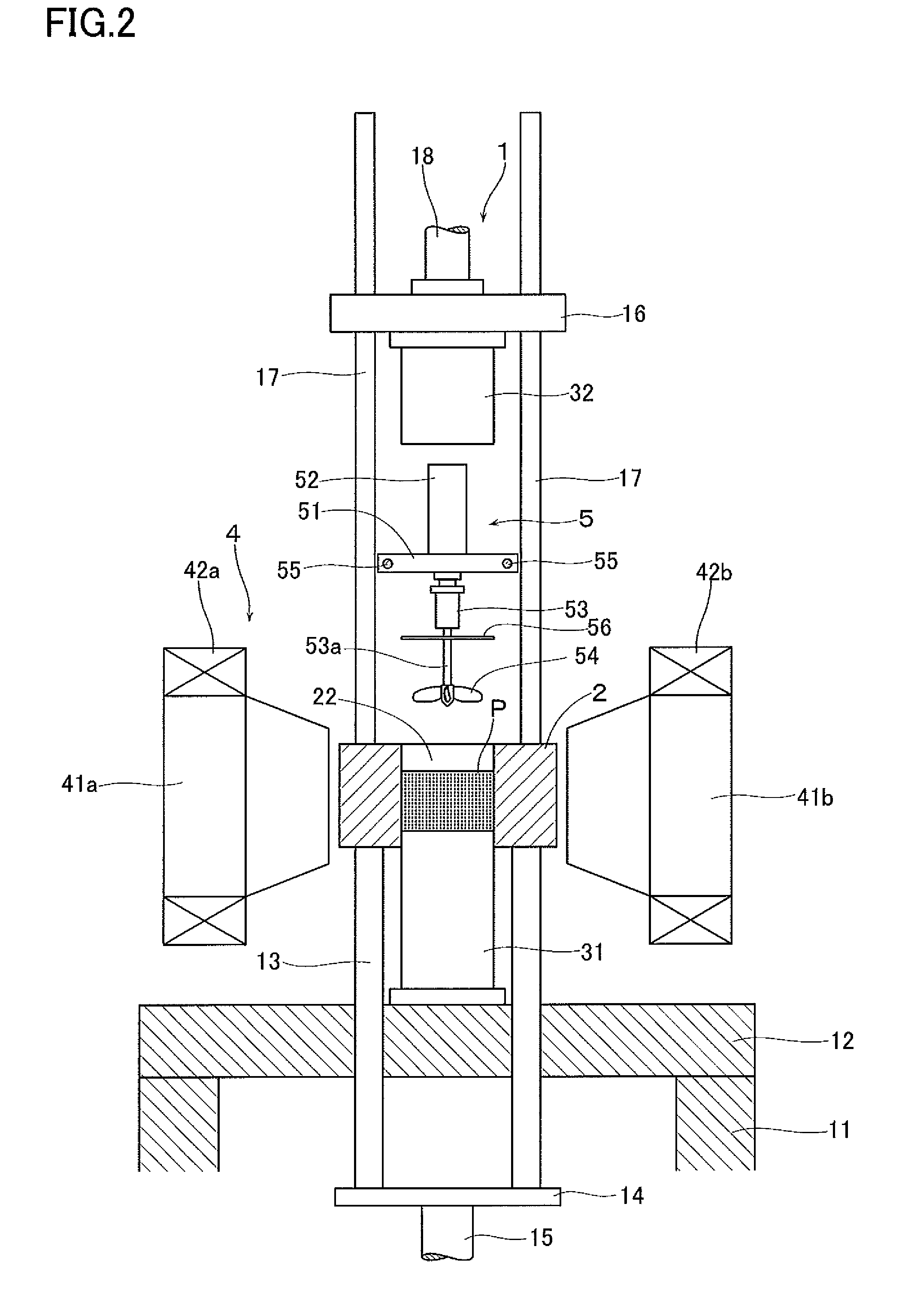

[0018]With reference to FIGS. 1 through 5, reference numeral 1 denotes a molding apparatus according to this invention. The molding apparatus 1 is suitable for manufacturing rare earth permanent magnet, in particular, Nd—Fe—B sintered magnet (inclusive of oriented body and molded body). The molding apparatus 1 is a compression molding apparatus of a uniaxial pressurizing type in which the direction of pressurizing (pressing direction) is vertical to the direction of magnetic orientation, and has a base plate 12 which is supported by leg pieces 11. Above the base plate 12 there is disposed a die 2. The die 2 is supported by a plurality of supporting columns 13 which penetrate through the base plate 12. The other end of each of the supporting columns 13 is connected to a connecting plate 14 disposed below the base plate 12. The connecting plate 14 is connected to a driving means, e.g., a cylinder rod 15 of a hydraulic cylinder of a known construction. According to this configuration, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com