Vacuum storage bag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

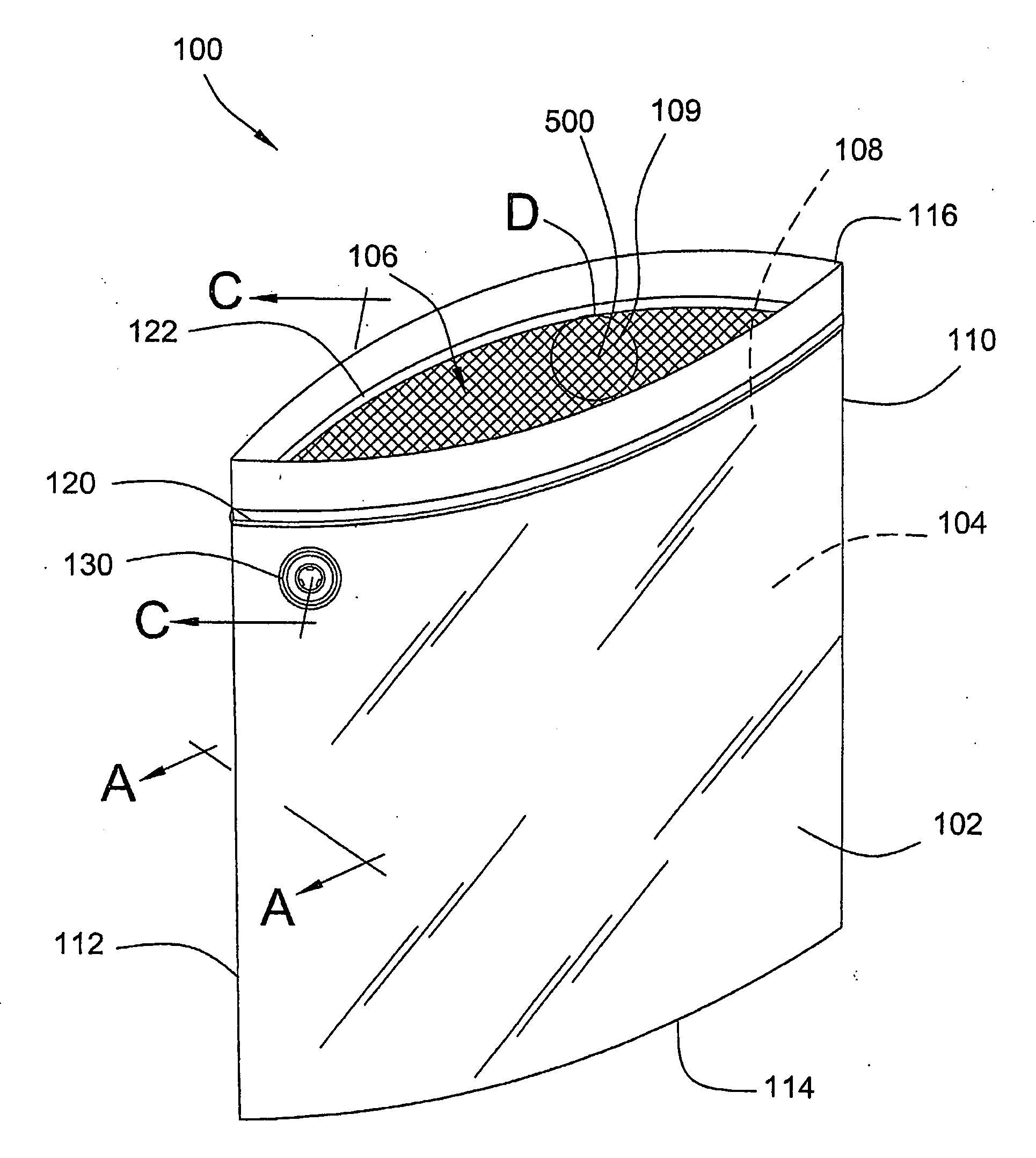

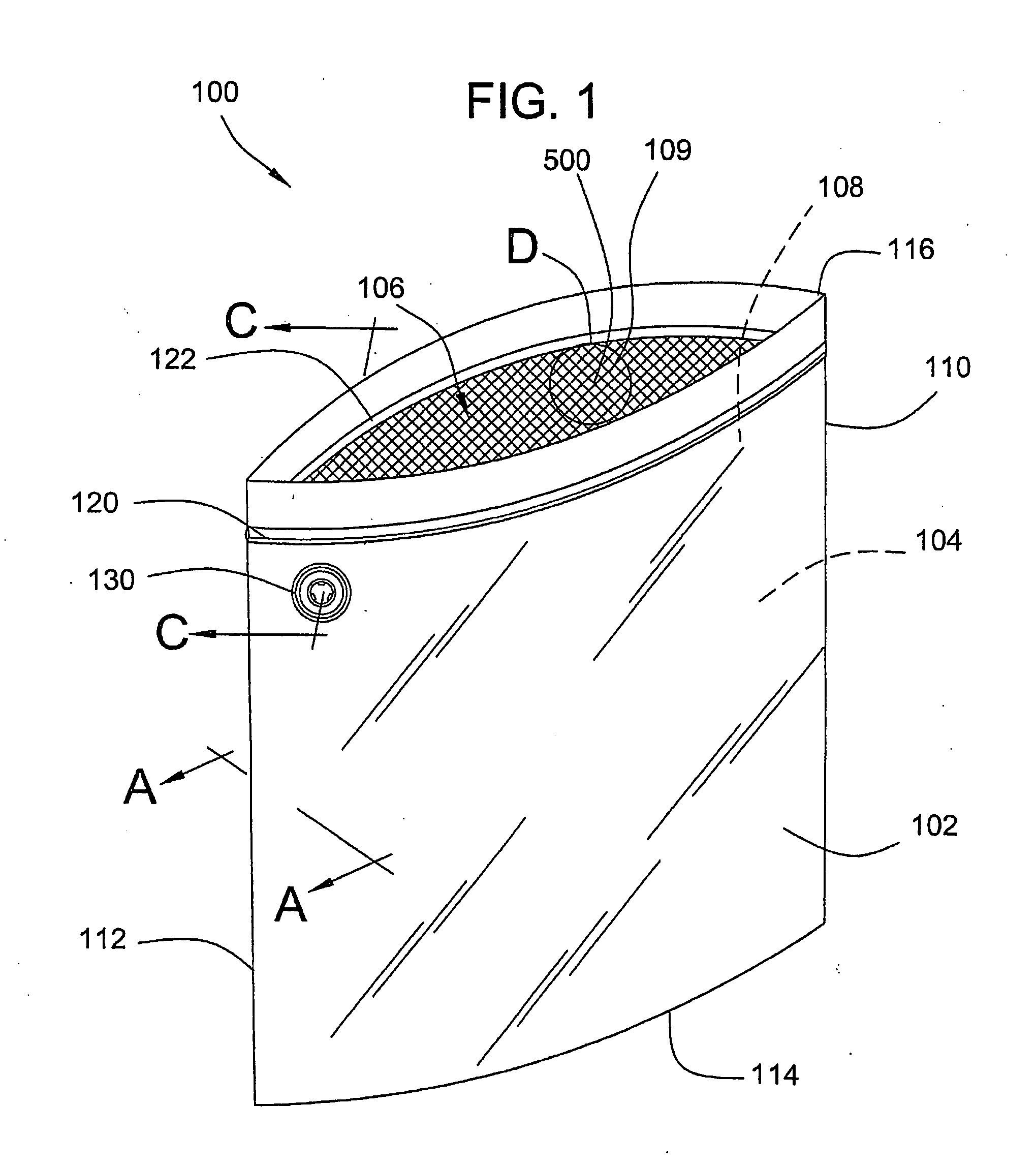

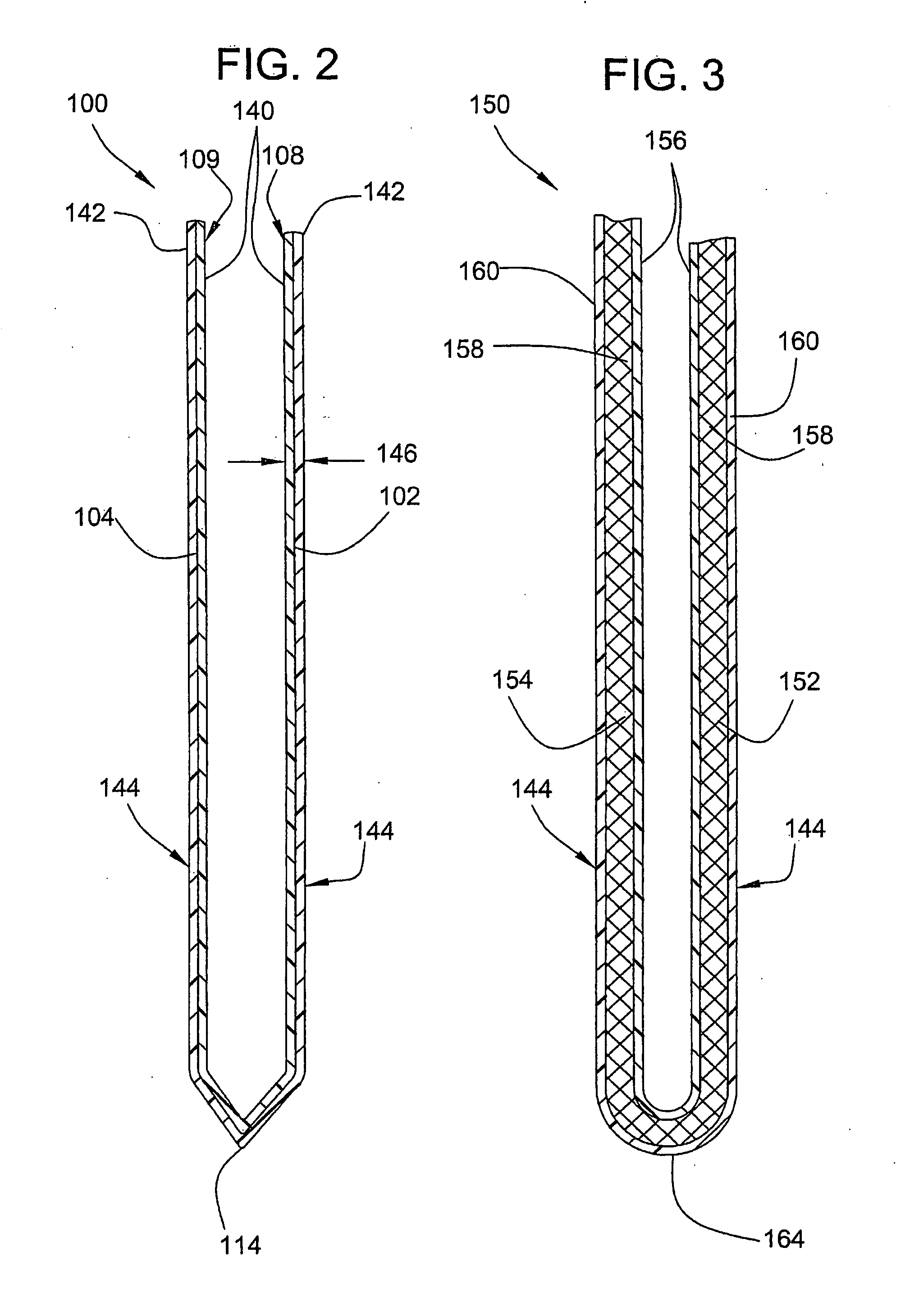

[0021]Now referring to the drawings, wherein like reference numbers refer to like features, there is illustrated in FIG. 1 a vacuum storage bag 100 made of flexible materials that can be used for the vacuum storage of food items. In the illustrated embodiment, the storage bag 100 includes a first sidewall 102 and an opposing second sidewall 104 overlaying and joined to the first sidewall so as to provide an interior volume 106. Accordingly, each of the first and second sidewalls 102, 104 has a respective inner surface 108, 109. To join the first and second sidewalls 102, 104 together, heat seals are formed along a first side edge 110, a parallel second side edge 112, and a closed bottom edge 114 that extends between the first and second side edges 102, 104. To access the interior volume 106, an opening 116 is provided by allowing the portions of the first and second sidewalls 102, 104 corresponding to the top edge opposite the closed bottom edge 114 to remain unjoined. Due to the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com