Ag-bi-base alloy sputtering target, and method for producing the same

a technology of bi-base alloy and sputtering target, which is applied in the manufacture of diaphragms, optical record carriers, and record information storage. it can solve the problems of sputtering target a multitude of crystal defects, current availability of ag films may encounter deterioration, and obtained pure ag films, etc., and achieve the effect of suppressing the remarkable lowering of the yield of bi content in films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

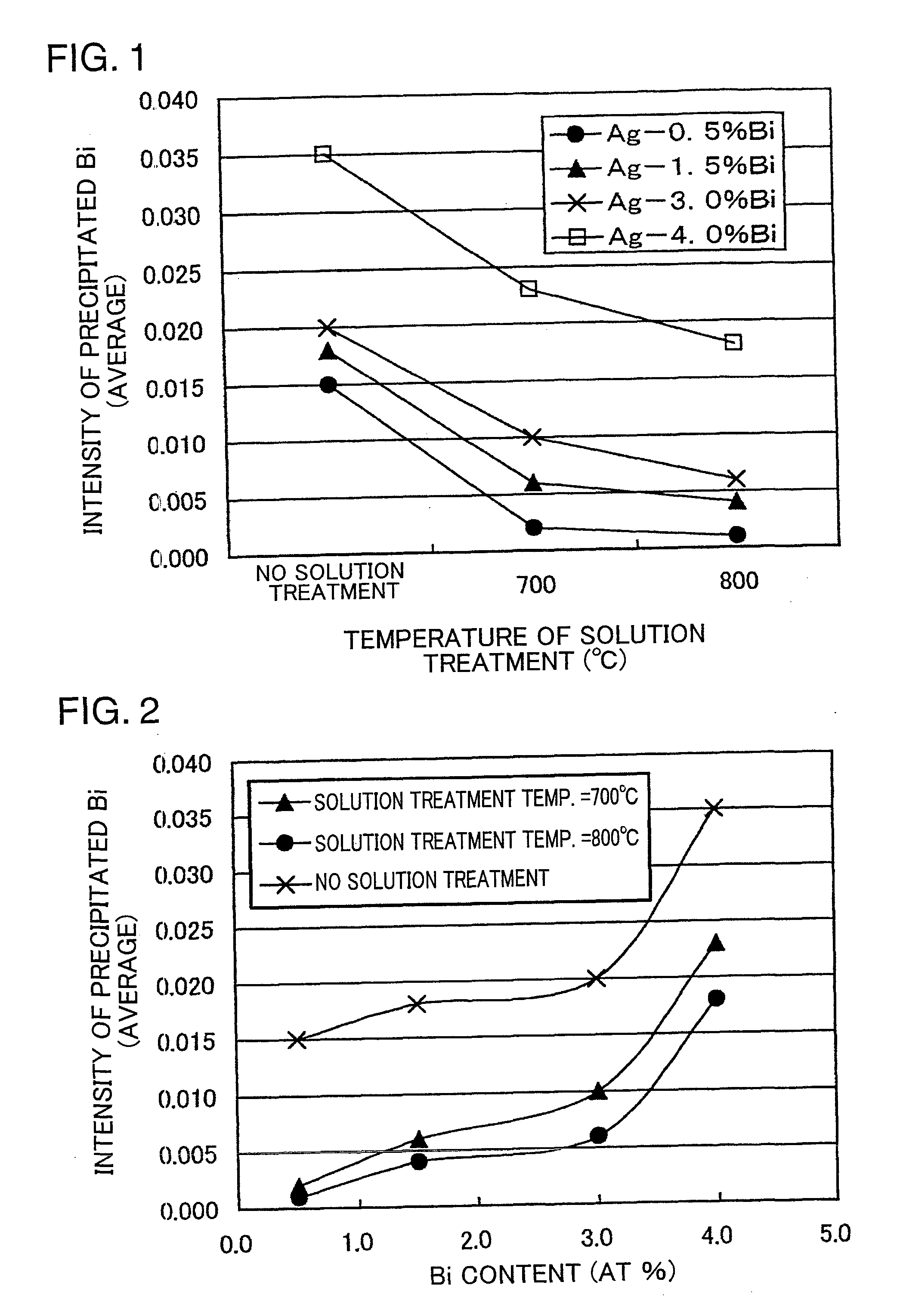

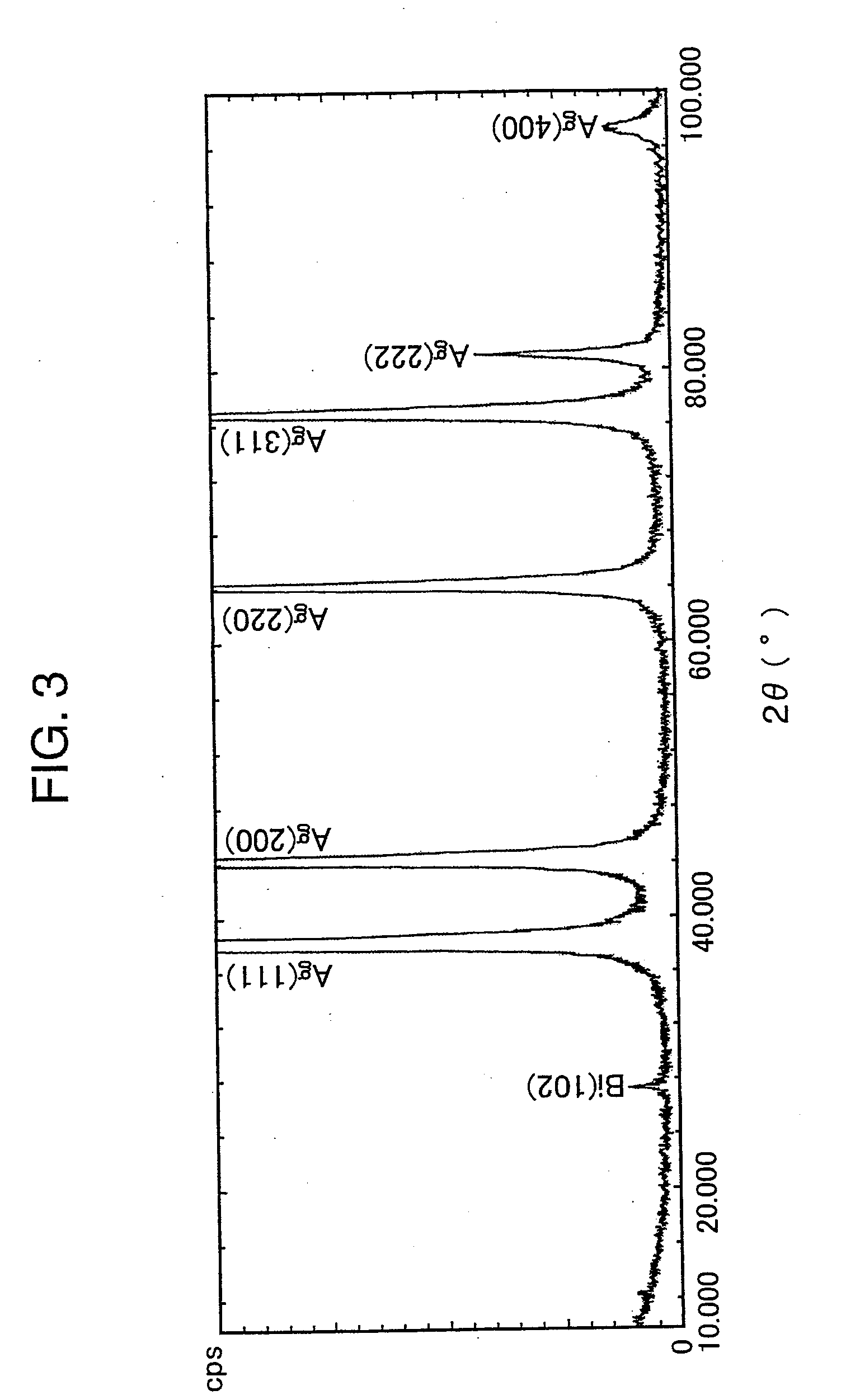

[0070]Ag and Bi whose compositions had been adjusted were inductively melted under Ar gas atmosphere, and produced were four different kinds of Ag—Bi alloy ingots each having a different Bi content, namely, Ag with Bi of 0.5 at %, Ag with Bi of 1.5 at %, Ag with Bi of 3.0 at %, and Ag with Bi of 4.0 at %. Three different kinds of treatments were performed with respect to each of the four Ag—Bi alloy ingots: the first treatment was no solution treatment; the second treatment was a solution treatment of temperature: 700(° C.)—time: 10(hr)—cooling rate: 5° C. / min; and the third treatment was a solution treatment of temperature: 800(° C.)—time: 10(hr)—cooling rate: 5° C. / min.

[0071]After either one of the three treatments was implemented, these ingots were subjected to hot working at a hot work initiate temperature of 700° C., and rolling reduction [={(plate thickness before hot rolling)−(plate thickness after hot rolling)} / (plate thickness before hot rolling)] of 50%. Thus, hot rolled p...

example 2

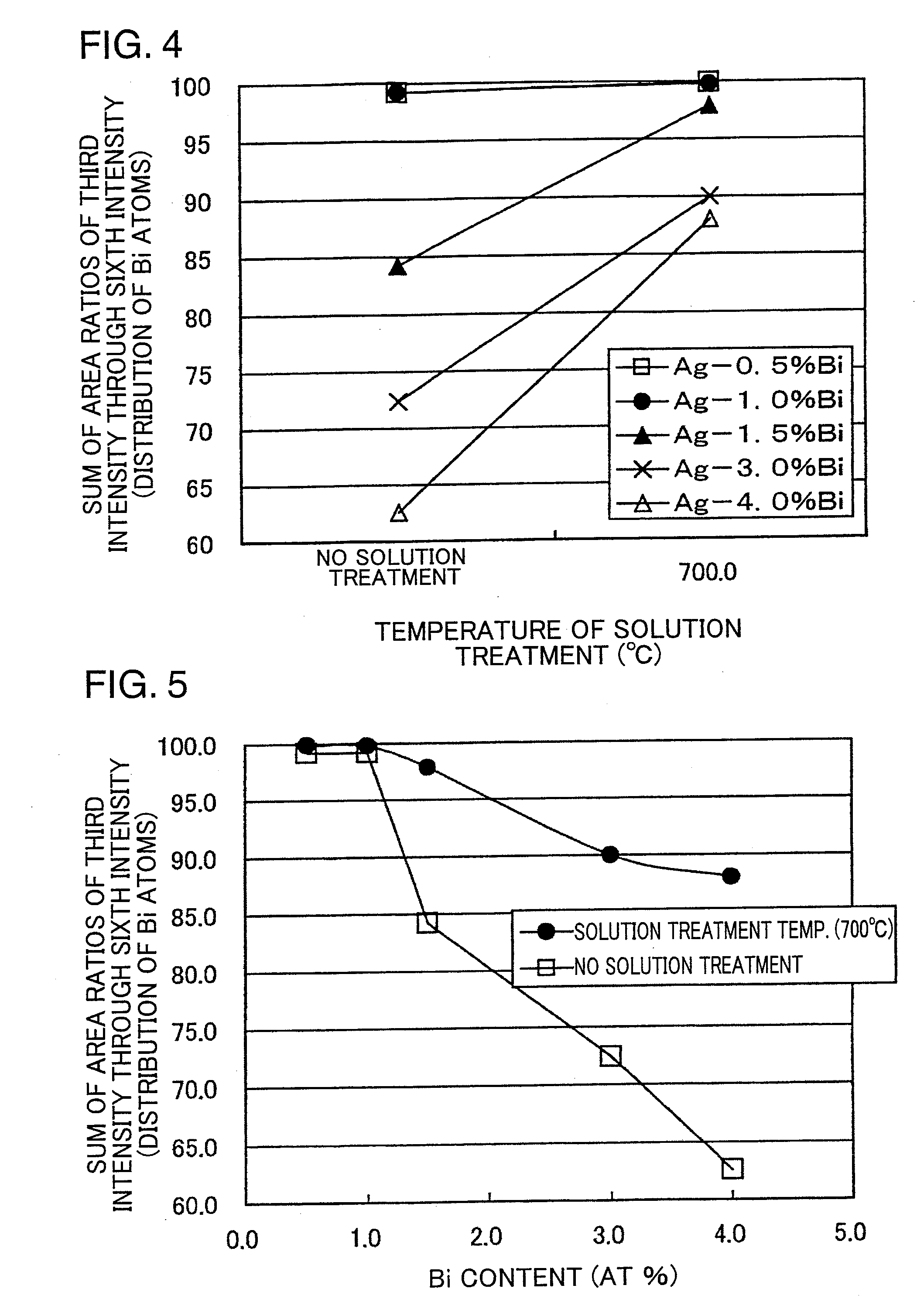

[0074]Ag and Bi whose compositions had been adjusted were inductively melted under Ar gas atmosphere, and produced were five different kinds of Ag—Bi alloy ingots each having a different Bi content, namely, Ag with Bi of 0.5 at %, Ag with Bi of 1.0 at %, Ag with Bi of 1.5 at %, Ag with Bi of 3.0 at %, and Ag with Bi of 4.0 at % by casting the materials into metal plates with use of a mold. Two different kinds of treatments were performed with respect to each of the five Ag—Bi alloy ingots: one was no solution treatment; and the other was a solution treatment of temperature: 700(° C.)—time: 4(hr)—cooling rate: 5° C. / min. After either one of the treatments was implemented, these ingots were subjected to hot rolling at a hot roll initiate temperature of 700° C., and rolling reduction of 50%, followed by cold rolling (rolling reduction: 50%) and heat treatment (temperature: 600° C., time: 1.5 hr).

[0075]Ag—Bi alloy sputtering targets (diameter: 101.6 mm, thickness: 5 mm) were obtained by...

example 3

[0081]Ingots were produced in a similar manner as producing the ingot made of the Ag—Bi alloy with Bi content of 1.5 at % in Example 1, and hot rolled plates were obtained by subjecting the ingots to hot working at a hot work initiate temperature of 650° C. and rolling reduction of 70% except that the solution treatment were differentiated from each other in the samples. After the hot rolled plates were subjected to cold rolling (rolling reduction: 50%) and heat treatment (temperature: 600° C., time: 1.5 hr), sputtering targets (diameter: 101.6 mm; thickness: 5 mm), and a certain number of test chips of 20 mm (length)×20 mm (width)×5 mm (thickness) necessary for implementing the experiments were obtained by cutting or shaving the plates.

[0082]Evaluation results of Example 3 are shown in Table 3.

TABLE 3Sum of arearatiosAverageof 3rd to 6thcrystalSolution treatmentIntensityintensitiesgrain sizeconditionsof precipitated(distributionafterOversizedCoolingBiofsolutiongrowthSampleTemp.Time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com