Devices and methods of copper recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

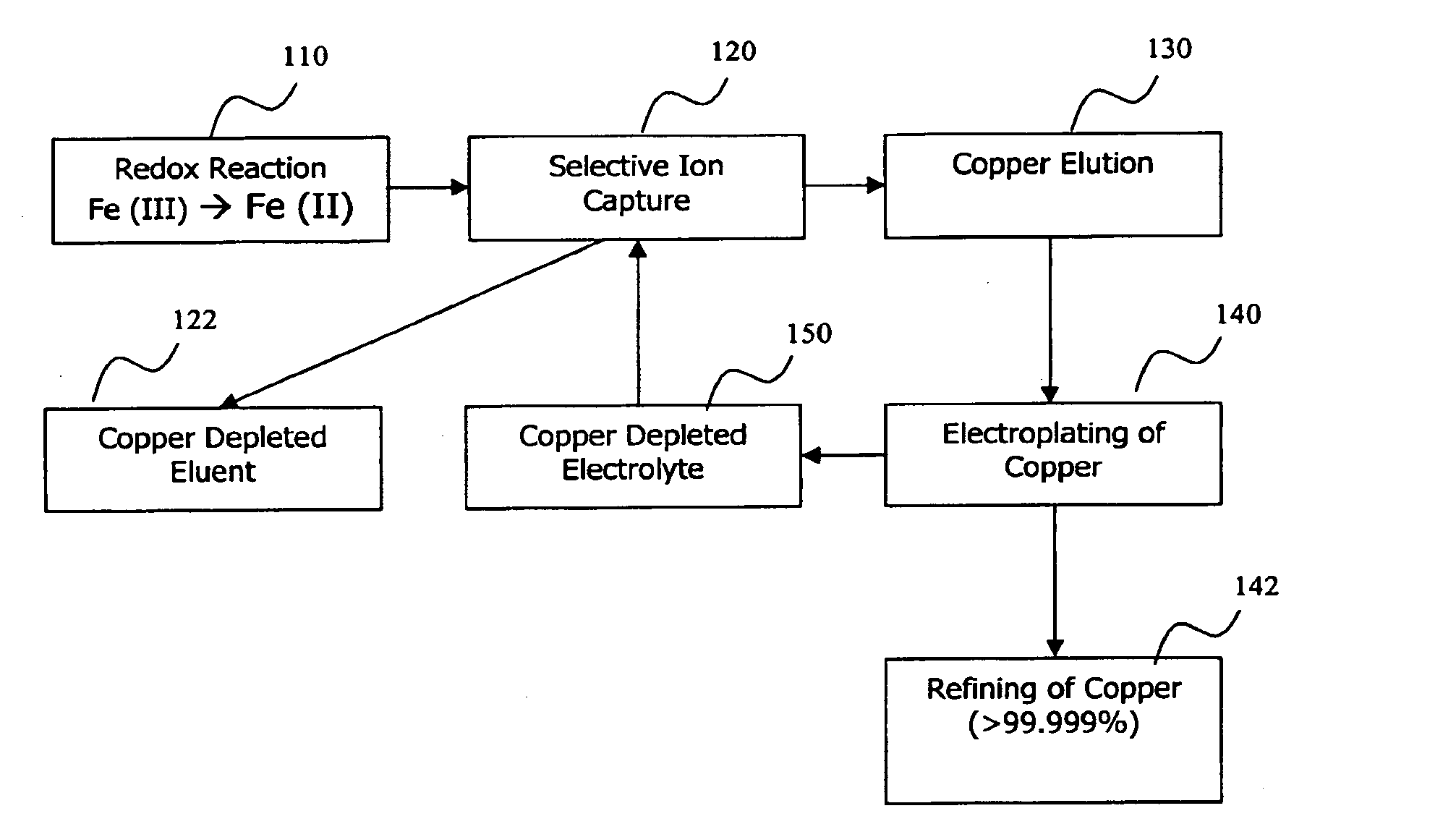

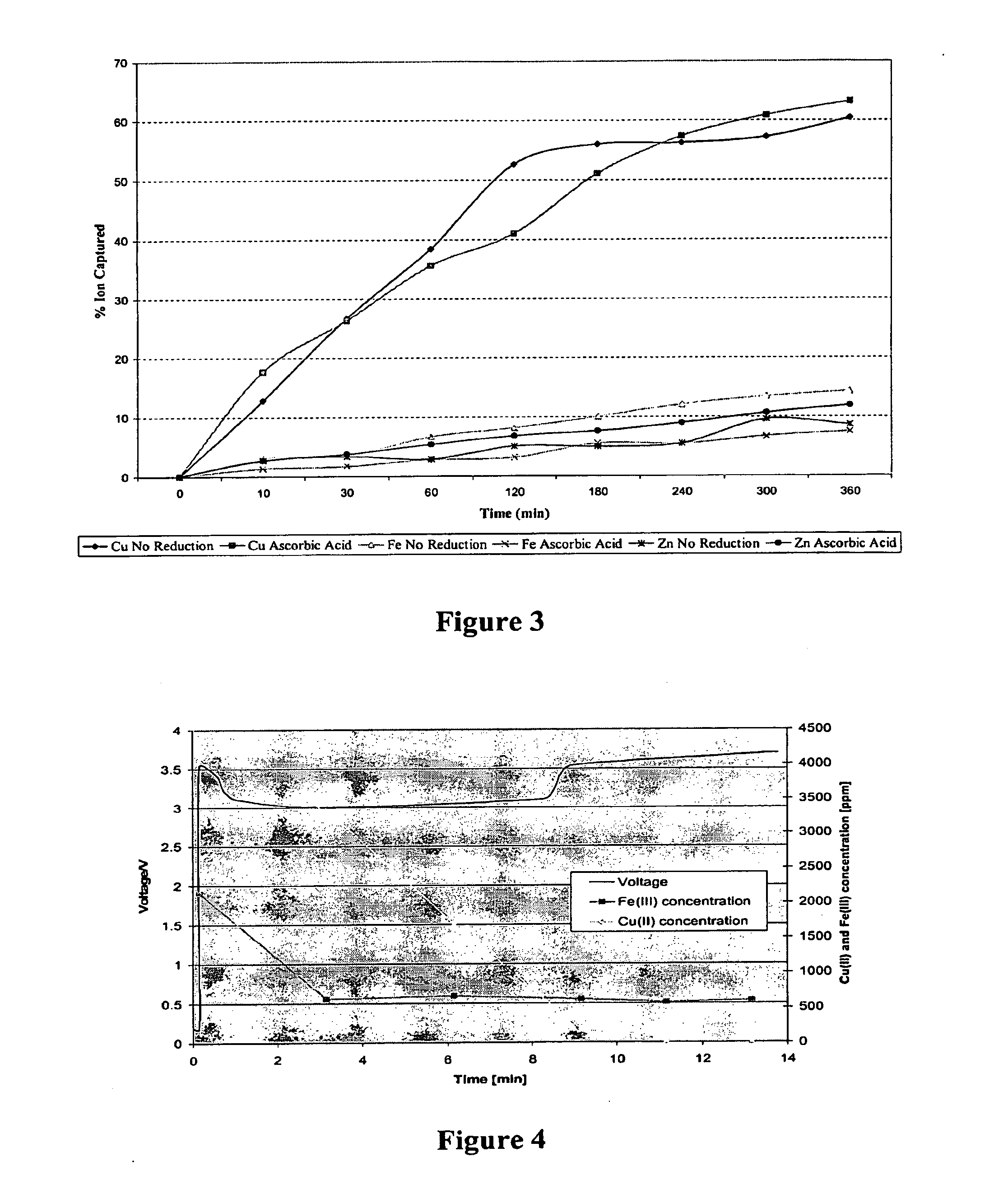

[0025]The inventors have unexpectedly discovered that various metals, and especially metals at low to moderate concentrations (e.g., less than 1000 ppm) can be effectively and selectively recovered from an aqueous medium in which other metals are present by using a process that employs a redox reaction to reduce enrichment and / or plating interference from other metals, that selectively enriches the target metal to form a enriched medium, and that then plates the target metal from the enriched medium in a flow through electrode.

[0026]Contemplated configurations and methods are particularly desirable for treatment of copper containing acid mine drainage solutions and has been shown to produce high quality copper in a current efficient and economical manner. Such achievement is particularly notable as mine waste solutions are often richer in iron, zinc, and sulfuric acid than the target metal copper, and may further have significant buffering capacity (e.g., due to calcium, magnesium, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Reduction potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com