A kind of auxiliary brightener for potassium chloride zinc plating and preparation method and use thereof

A technology of auxiliary brightener and potassium chloride, applied in the field of auxiliary brightener, can solve the problems of high current density, blackening waste rate, etc., and achieve the effects of high current efficiency, low equipment corrosion, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

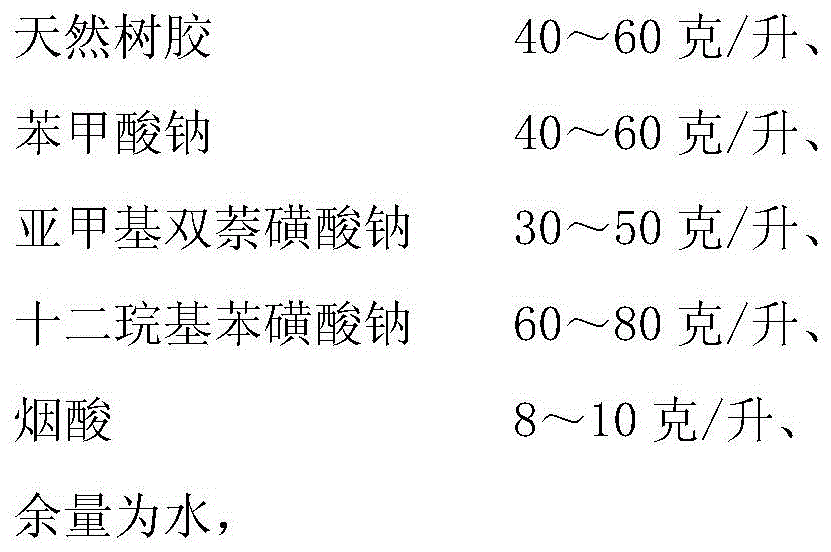

[0060] Ingredients and dosage of formula raw material for carrier brightener for plating solution:

[0061]

[0062] Preparation method of carrier brightener for plating solution:

[0063] Grind 5 kg of natural gum into powder with a pulverizer, put it into a 100-liter reaction kettle in an equal amount and add it under stirring, heat it with water to 95-100°C to dissolve it, and use a filter to dissolve it. Filter out impurities, and then lower the temperature to 80°C; then, add 5 kg of sodium benzoate, 4 kg of sodium methylene bis-naphthalene sulfonate, and 7 kg of sodium dodecylbenzene sulfonate in equal amounts while stirring. method, put it into the reaction kettle, dissolve it, and stir for 1 hour at a temperature of 90-95°C; finally, when the temperature of the reaction kettle is lowered to 60°C, add 0.9 kg of nicotinic acid in an equal amount while stirring , to dissolve, add water to a volume of 100 liters, and stir evenly.

Embodiment 2

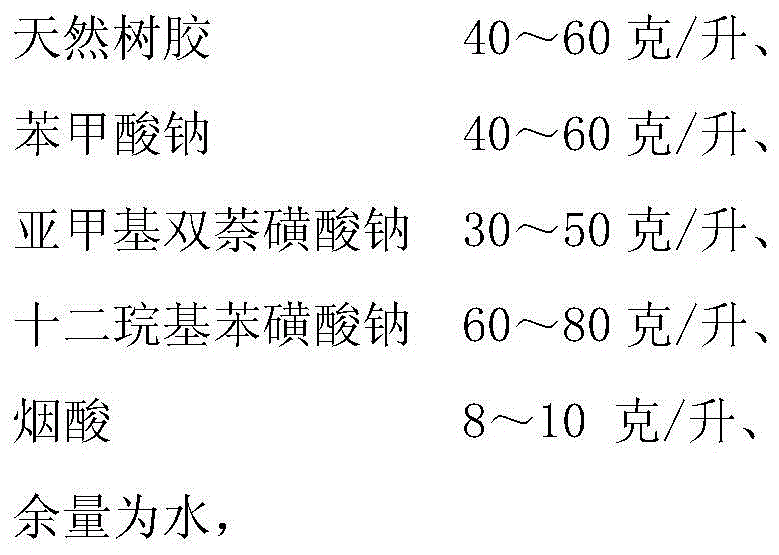

[0065] Ingredients and dosage of formula raw material for carrier brightener for plating solution:

[0066]

[0067] According to the ingredients and dosage of the formula raw materials, it is prepared with the same steps and operation method as in Example 1 for preparing the carrier brightener for the plating solution.

Embodiment 3

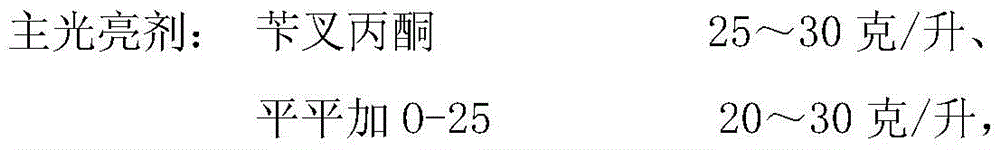

[0069] Ingredients and dosage of formula raw material for carrier brightener for plating solution:

[0070]

[0071]

[0072] According to the ingredients and dosage of the formula raw materials, it is prepared with the same steps and operation method as in Example 1 for preparing the carrier brightener for the plating solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com