Ferritic-austenitic stainless steel excellent in corrosion resistance and workability andmethod of production of same

a technology of austenitic stainless steel and corrosion resistance, which is applied in the field of ferric-austenitic stainless steel, can solve the problems of poor corrosion resistance low workability of ferritic stainless steel, and low workability of ferritic stainless steel, and achieves excellent corrosion resistance and high “uniform elongation”

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0149]Ferritic-austenitic stainless steel 250 mm thick cast slabs if the ingredients shown in Table 2 were produced and hot rolled into hot rolled steel plates with 5.0 mm plate thicknesses. Steel No. 1 to Steel No. 20 have ingredients defined in the present invention. Steel No. 21 to 26 have ingredients deviating from the definitions in the present invention. These hot rolled steel plates were annealed and pickled, then cold rolled to 1 mm thicknesses and final annealed. The final annealing was also performed under conditions deviating from the definitions of the present invention for comparison.

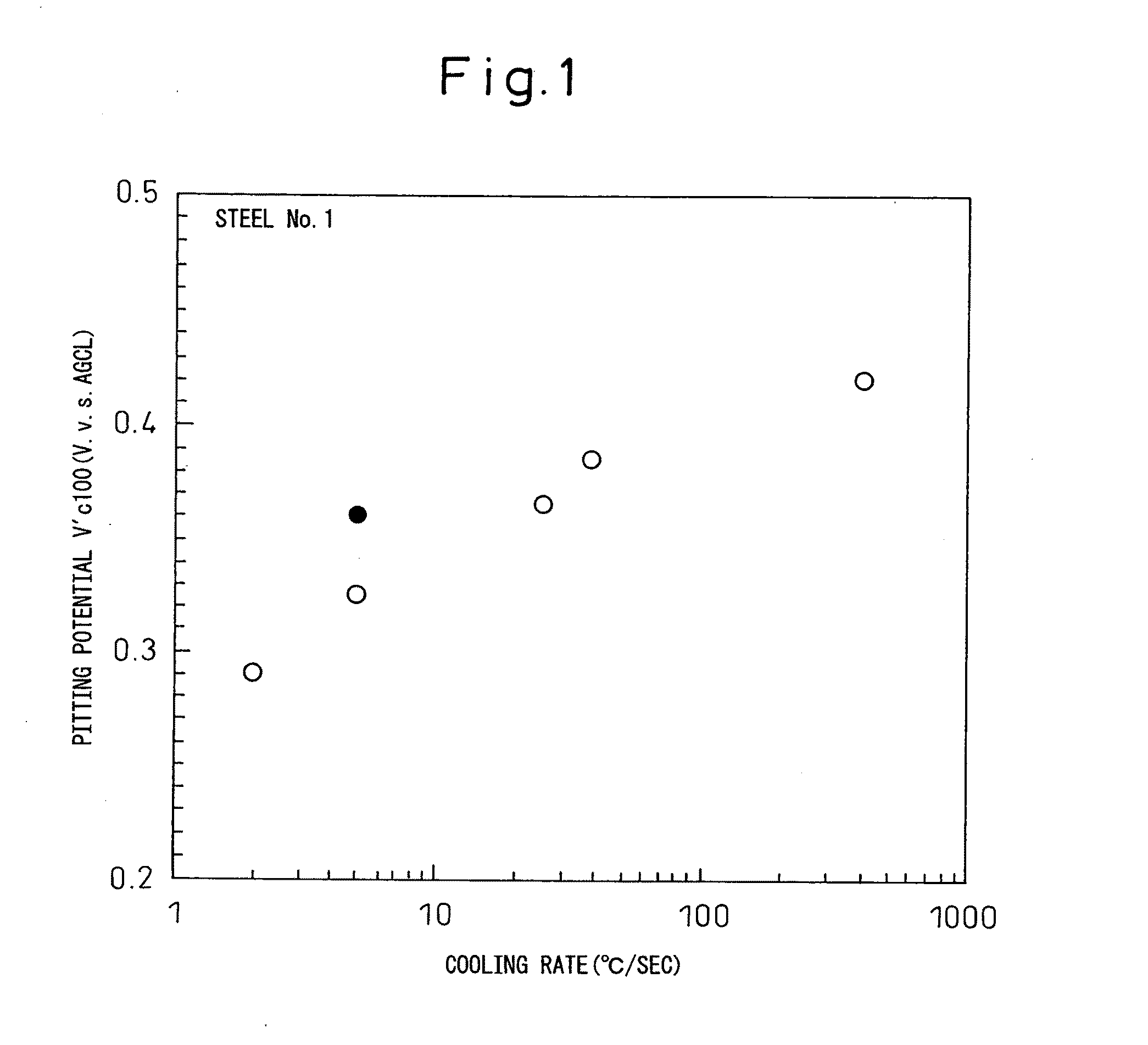

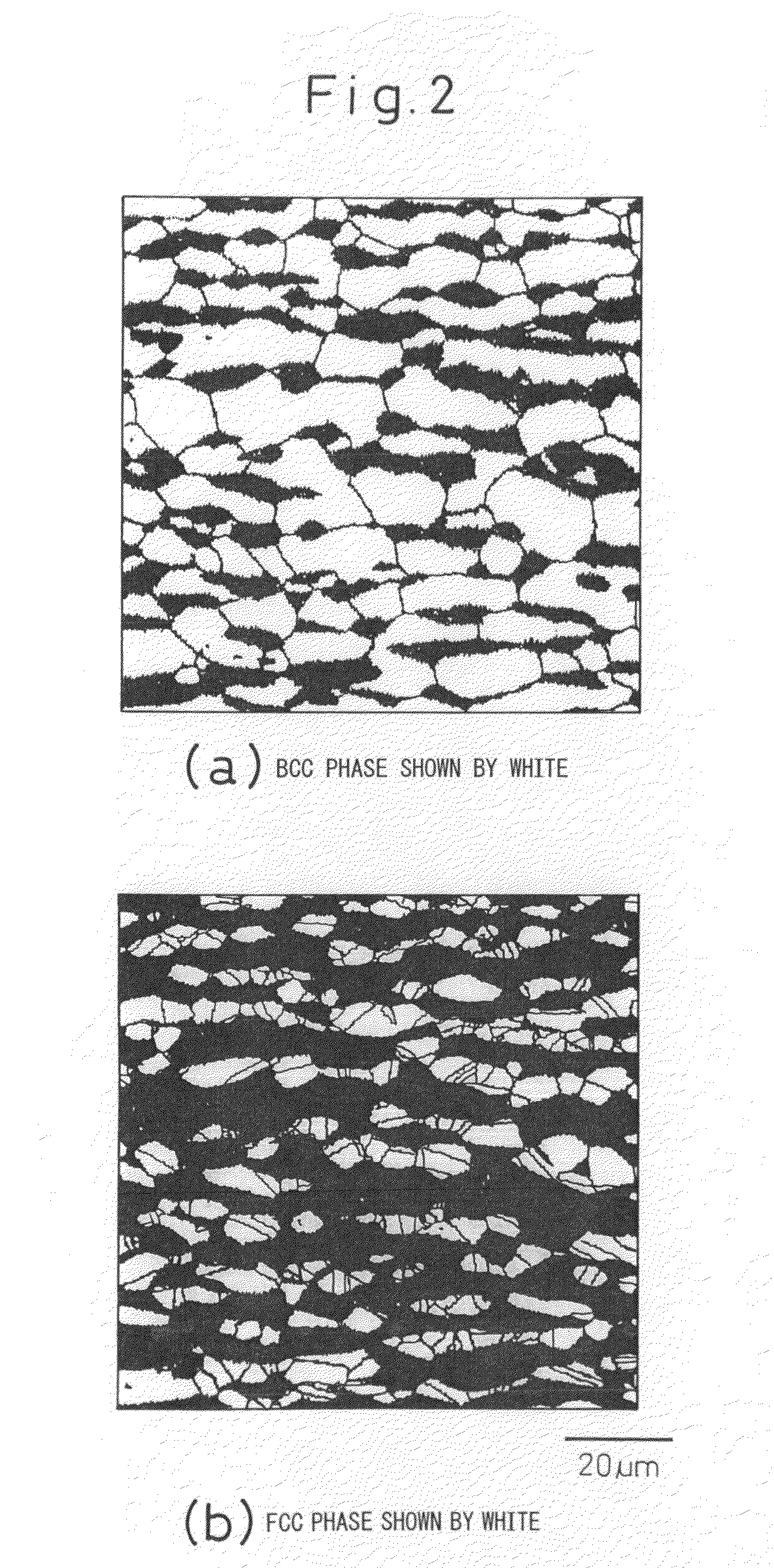

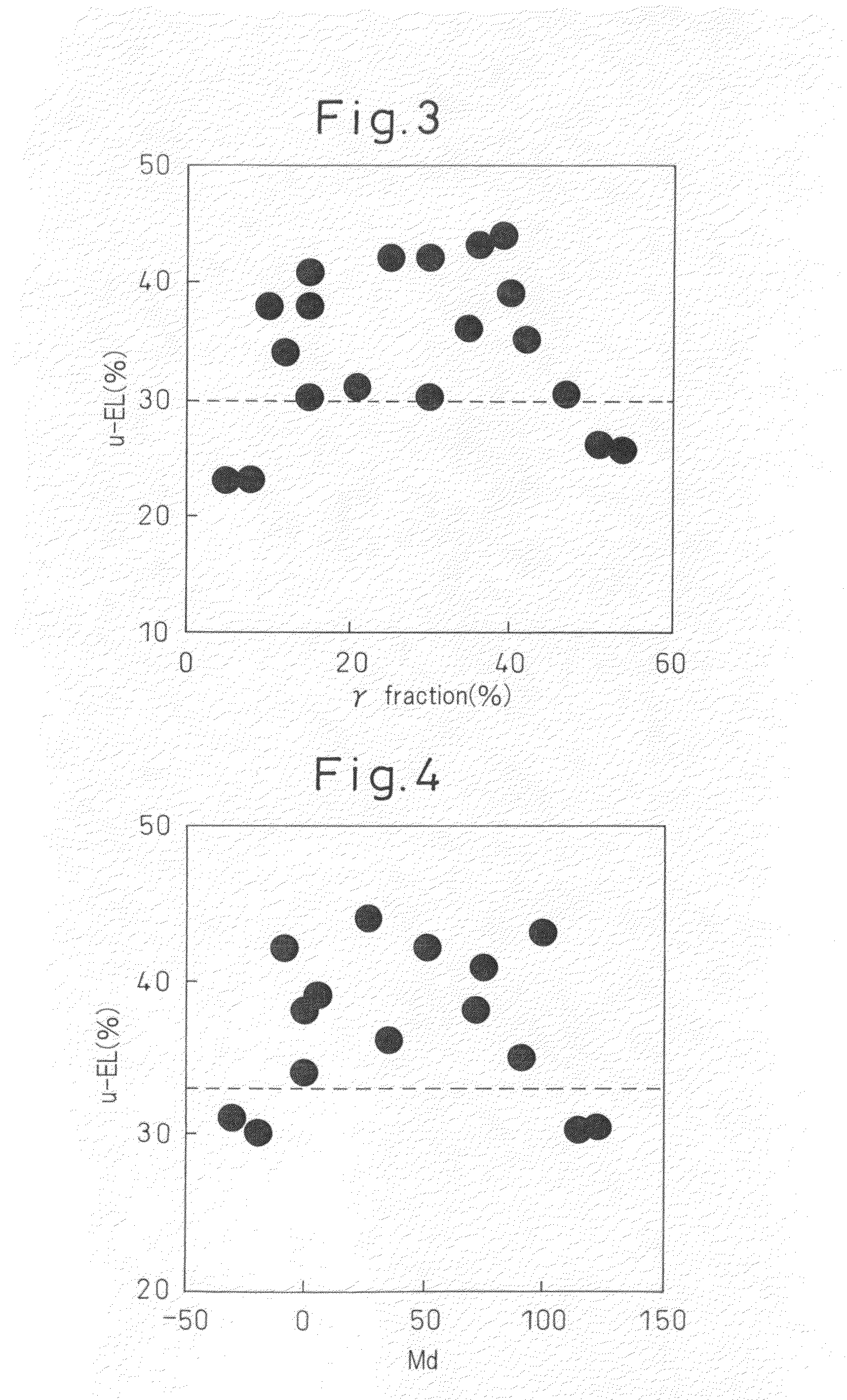

[0150]Various test pieces were taken from each of the obtained cold rolled and annealed sheets and evaluated for the γ phase volume fraction (γ fraction), pitting potential, and uniform elongation. The γ fraction was found by the EBSP method described in paragraph 0046. For the pitting potential, the V′c100 (Vv.s.AGCL) was measured for a #500 polished surface in a 30° C., 3.5% NaCl aqueous ...

example 2

[0155]Next, examples according to the second findings will be shown.

[0156]The steels shown in Table 4 were produced, then were hot rolled, then the hot rolled plates were annealed, cold rolled, and final annealed to produce 1.0 mm thick thin-gauge steel sheets. In producing the steel sheets, the metal structure can be changed by changing the material thickness, heating temperature of hot rolling, rolling pass schedule, rolling pass time, hot rolled sheet annealing temperature, and final annealing temperature and time. However, this time, the final annealing temperature was changed, and the annealing time was made 60 seconds. The obtained product sheets were subjected to tensile tests and the uniform elongation was measured. Further, from the metal structure of the thin-gauge steel sheet / L cross-section, the phases were identified by EBSP, the grain size and shape aspect ratio were investigated, and the distance between nearest grains of the austenite grains was measured. The conditi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume fraction | aaaaa | aaaaa |

| volume fraction | aaaaa | aaaaa |

| pitting potential Vc | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com