Composite house wrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

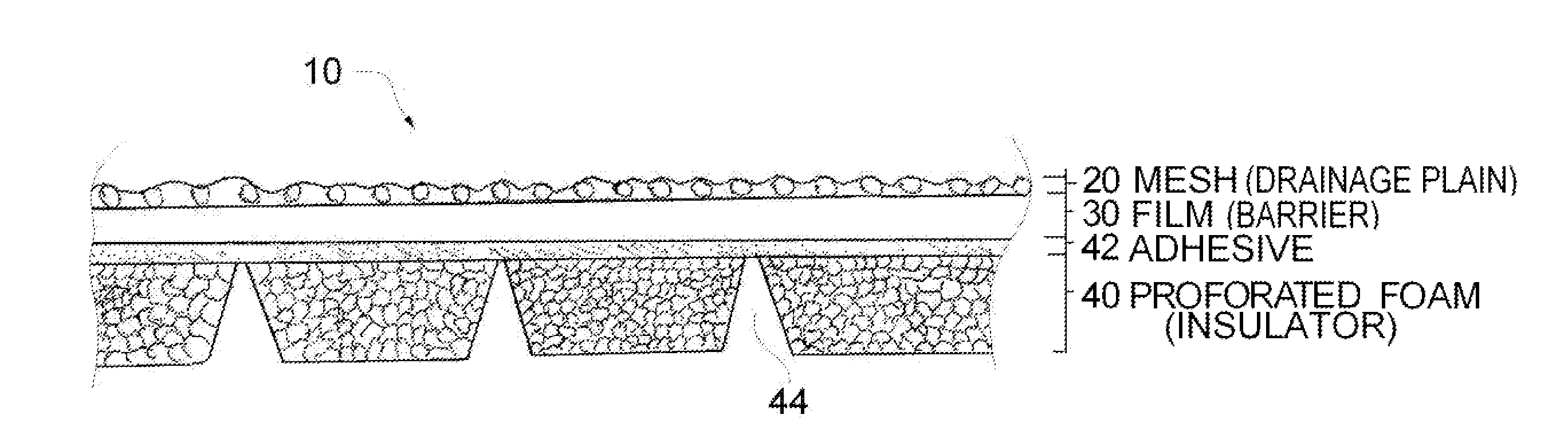

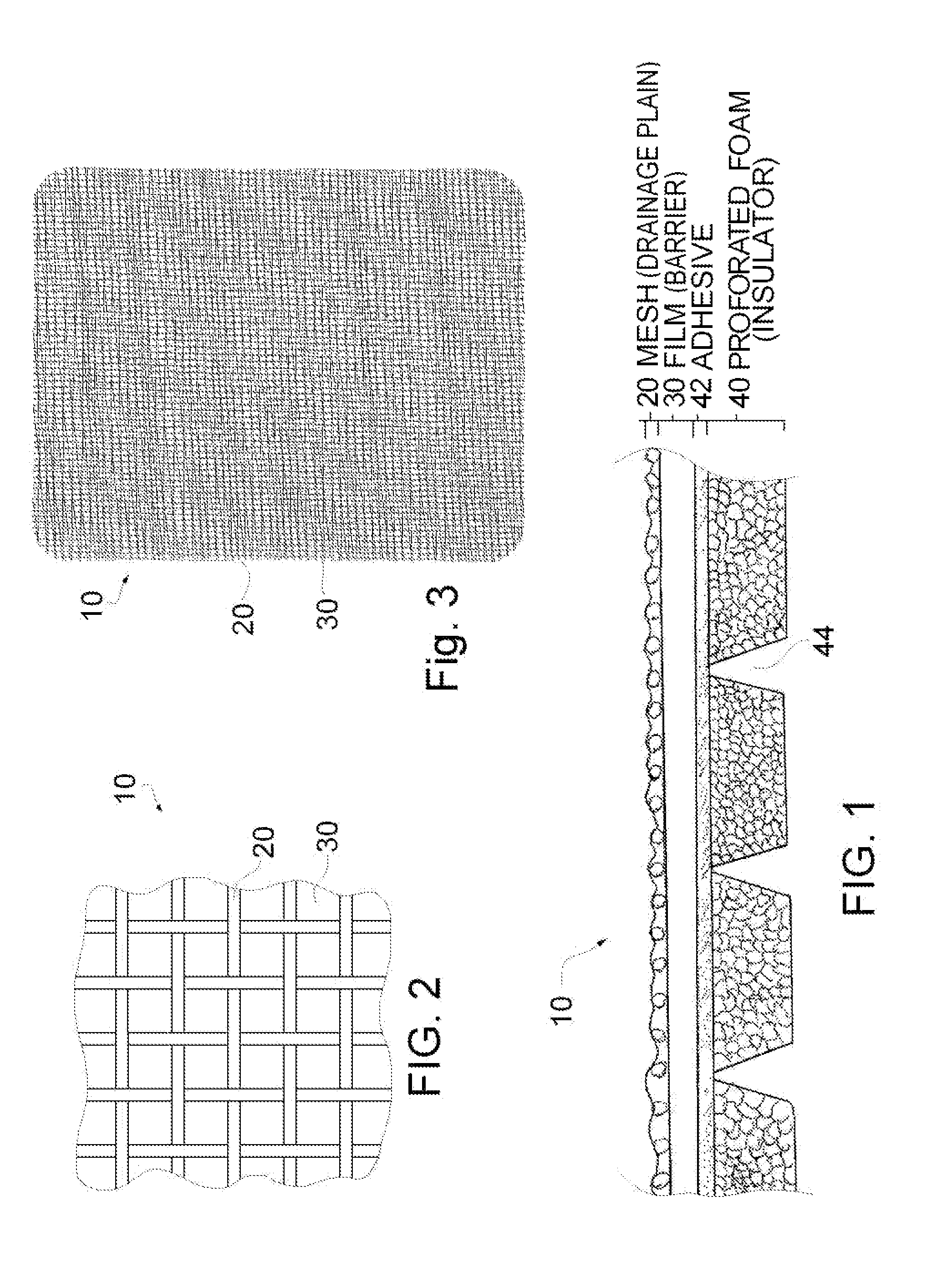

[0029]In summary, the present invention relates to a composite house wrap 10 is provided with three integral sections or layers 20, 30 and 40 as described below. The house wrap 10 according to the present invention will provide barrier protection plus moisture vapor transmission and an insulation R-value of approximately R2 or higher. The terms about or approximately or similar terms should be read as meaning within ten percent within this application. This house wrap 10 is specifically designed to add enhanced insulating characteristics as opposed to conventional house wraps, while maintaining a cost effective and easy to handle house wrap.

[0030]The house wrap 10 has a total thickness of about 25-30 mils, generally less than 40 mils, preferably less than 75 mils and effectively always less than 175 mils. The house wrap 10 can be attached to a building in any conventional fashion, such as nail guns, or the like. The house wrap 10 has the flexibility and durability that is comparable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com