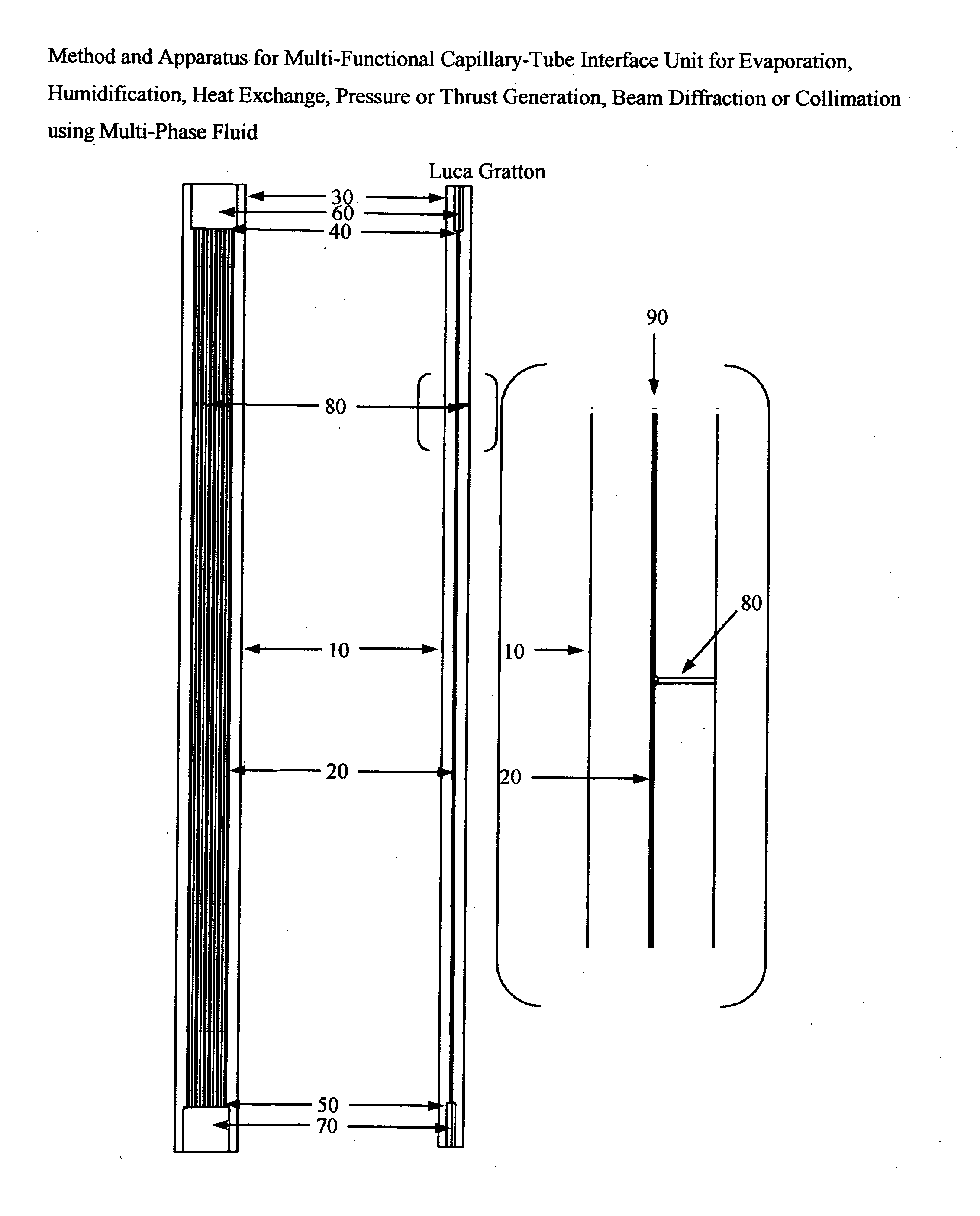

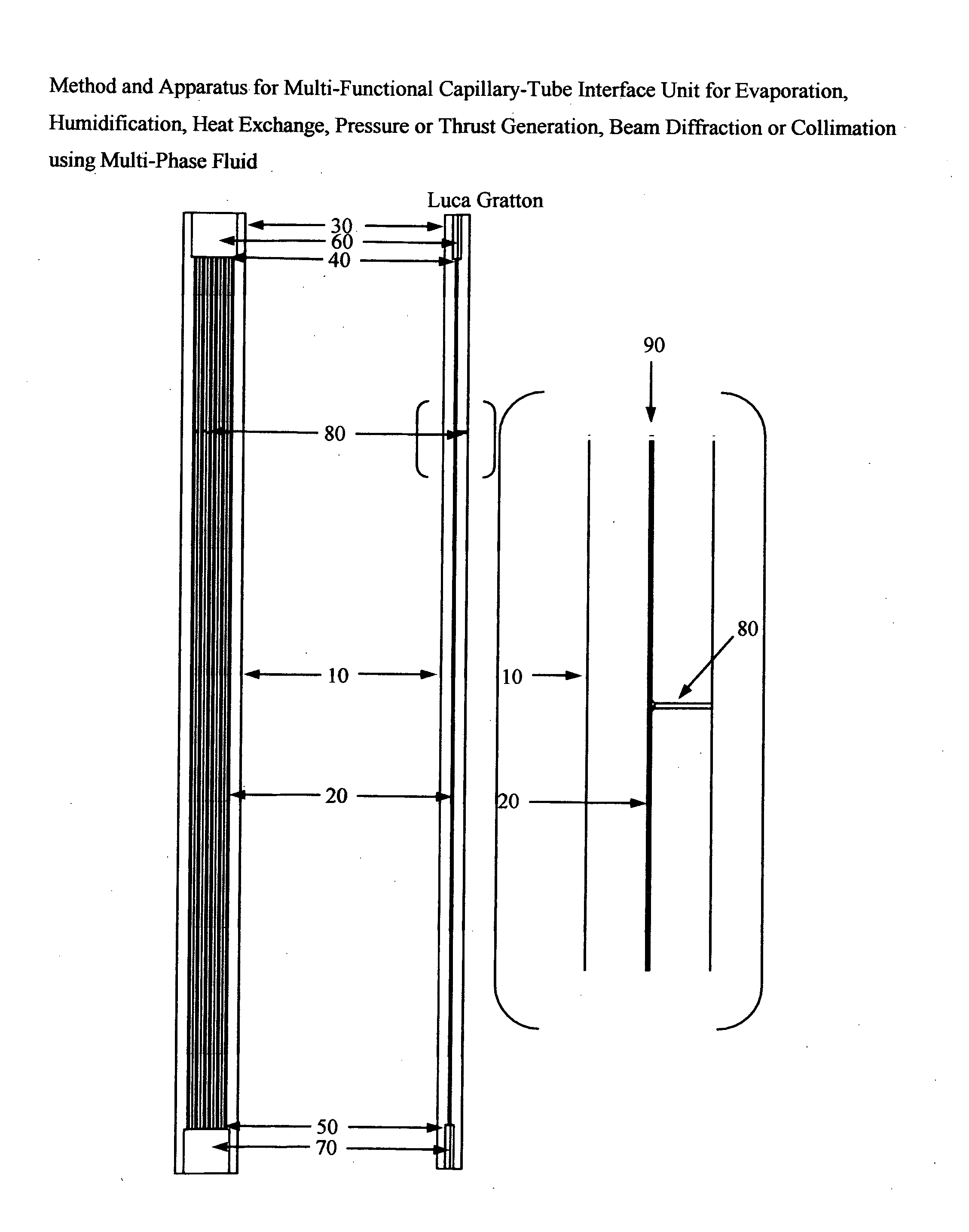

Method and apparatus for multi-functional capillary-tube interface unit for evaporation, humidification, heat exchange, pressure or thrust generation, beam diffraction or collimation using multi-phase fluid

a multi-functional, capillary tube technology, applied in the direction of indirect heat exchangers, heat transfer modification, lighting and heating apparatus, etc., can solve the problems of excessive liquid dryout, unacceptable overall system pressure or temperature differences,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]There is disclosed herein the methods and apparatus of the present invention that uses heat exchange with a volatile fluid in a capillary network to regulate fluid pressure and saturation level at specific locations throughout a miniature device. The volatile fluid may exist as one component in a multi-component fluid mixture. Variations of operational parameters and configuration for the miniature device allow-functional performance in any of eight application modes. These eight application modes are (1) Fluid Evaporator, (2) Fluid Condenser, (3) Gas Phase Humidifier with Working Fluid Vaporization, (4) Single-Stream Heat Exchanger with the Working Fluid, (5) Pressure Generator, (6) Thrust Motor, (7) a Doppler-Shift-Sensitive Fraunhofer Diffraction Device, or (8) a Doppler-Shift-Sensitive Collimation Device.

[0020]The capillary tube network consists of channels with parallel axes that penetrate a solid receiver module 10 (i.e., web) of FIG. 1. The capillary channel walls may f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com