Cryogenic propellant depot and deployable sunshield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

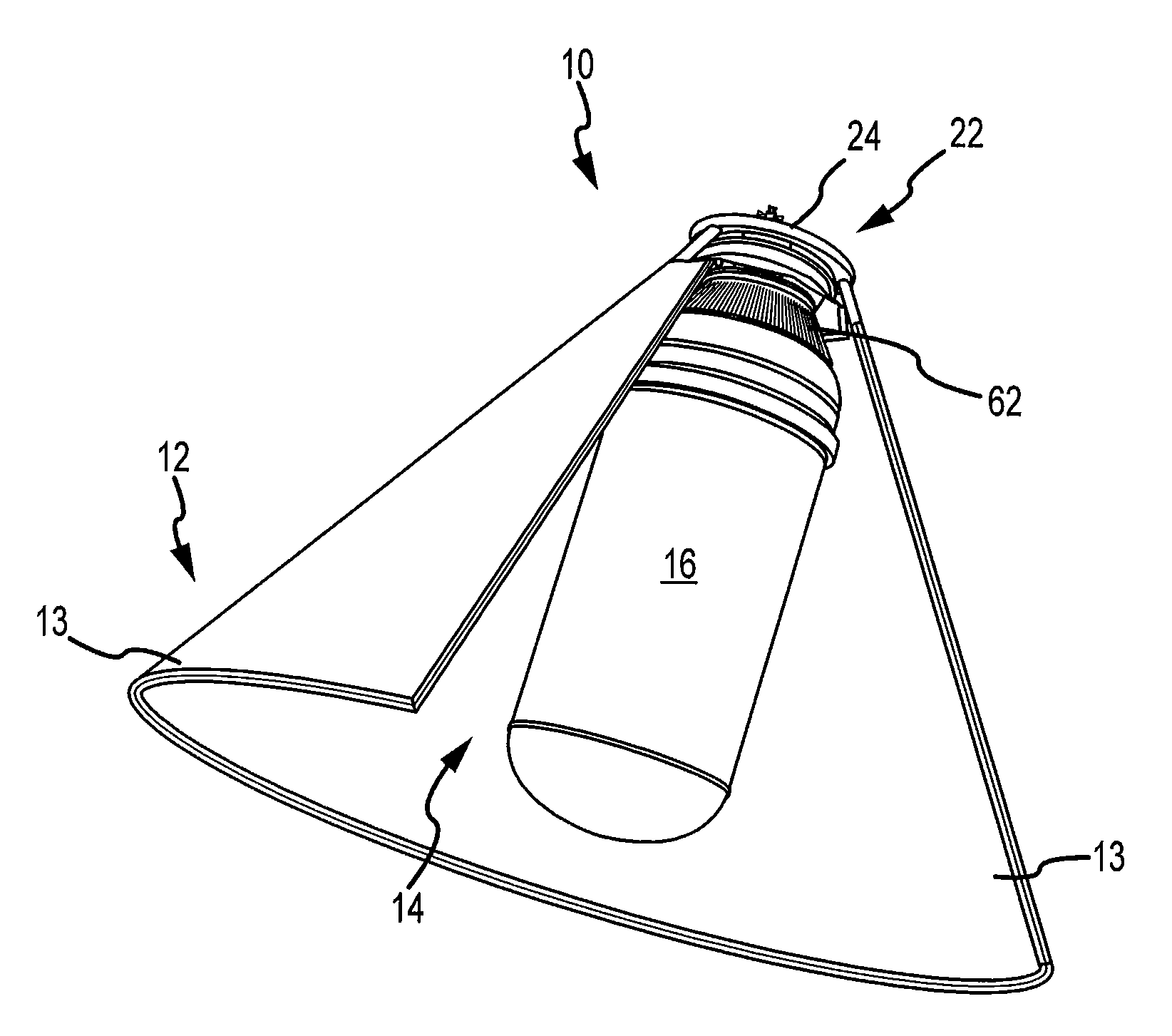

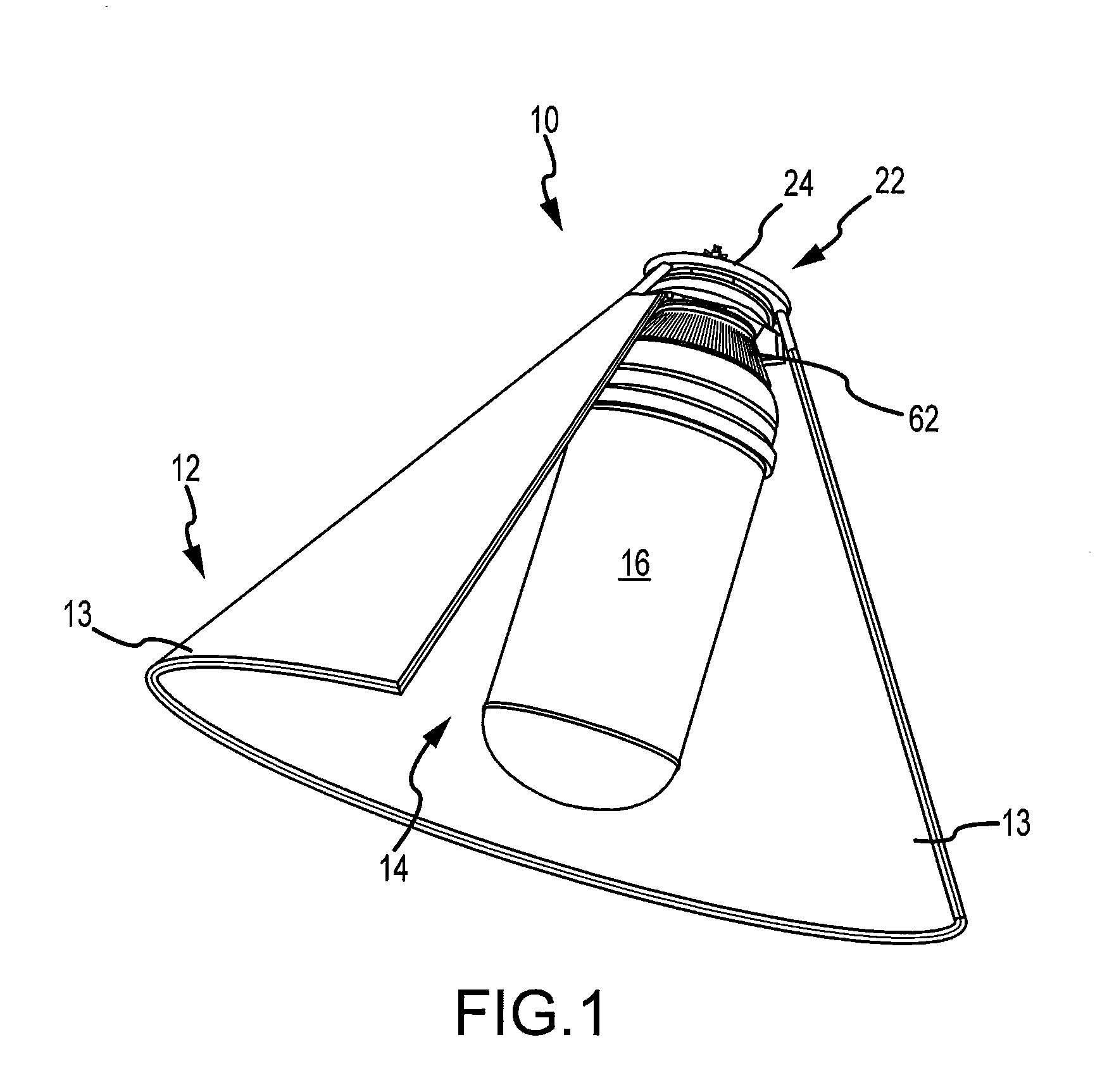

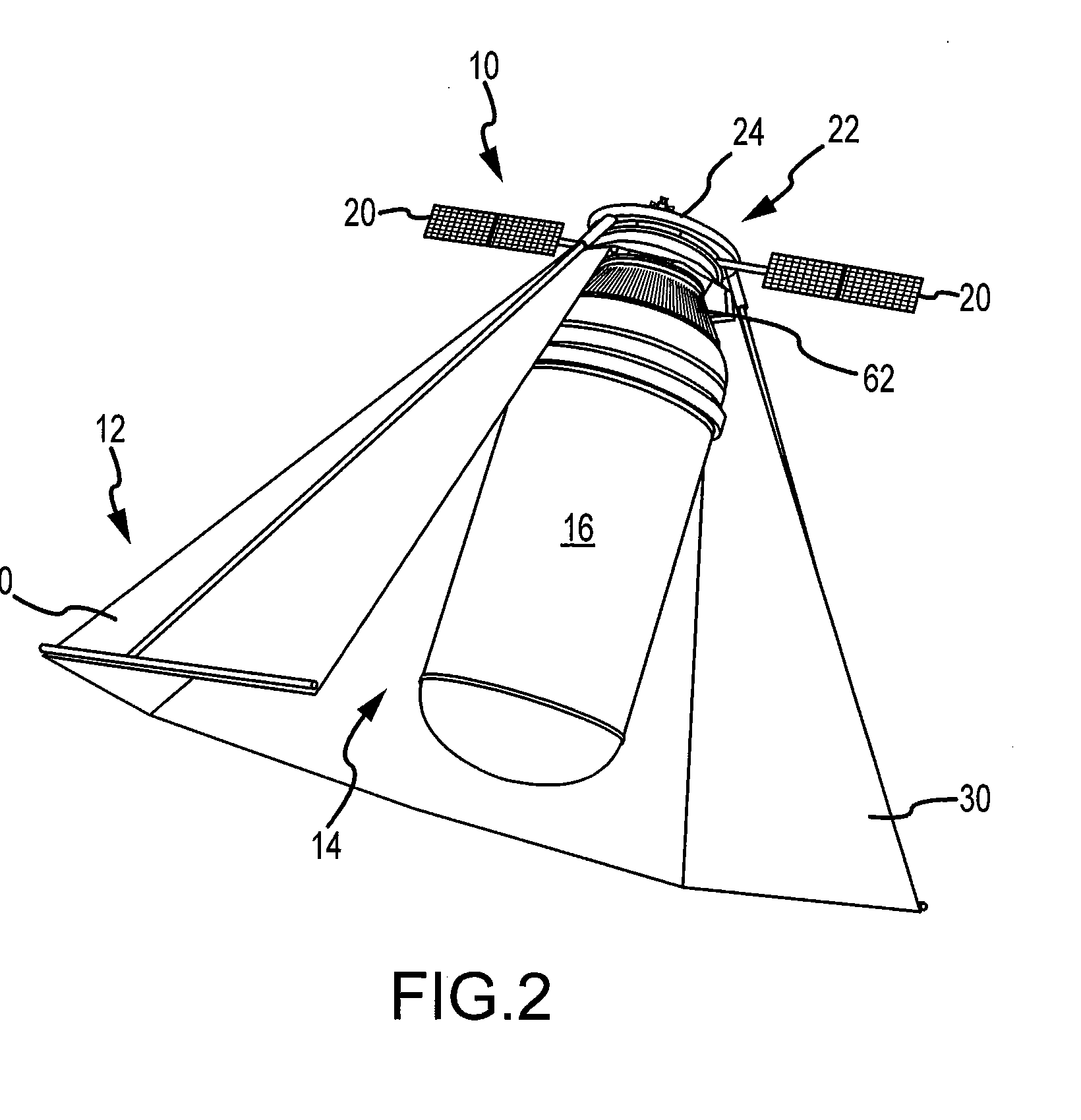

[0032]In accordance with the present invention and in one aspect of the invention, it includes a combination of a cryogenic propellant tank and an integral sunshield. According to this first aspect, the propellant tank can be incorporated as the upper stage of a launch vehicle further including a propulsion system that can carry a payload such as a satellite. In another aspect of the invention as a subcombination, it may be considered a sunshield especially adapted for space vehicles. In yet another aspect of the invention as a subcombination, it may be considered a cryogenic propellant tank placed in orbit and especially adapted for fueling and refueling space vehicles. In another aspect of the invention, a method is provided for deploying a sunshield for a space vehicle. In yet another aspect of the invention, a method is provided for providing a readily accessible liquid within a cryogenic tank while in earth orbit for transfer to another space vehicle.

[0033]FIG. 1 illustrates a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com