Liquid cooled compliant heat sink and related method

a heat sink and liquid cooling technology, applied in the field of heat sinks for cooling ic chips and packages, can solve the problems of significant reduction in thermal performance, the ability to remove heat from the chip, and the ic chip being exposed to high temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

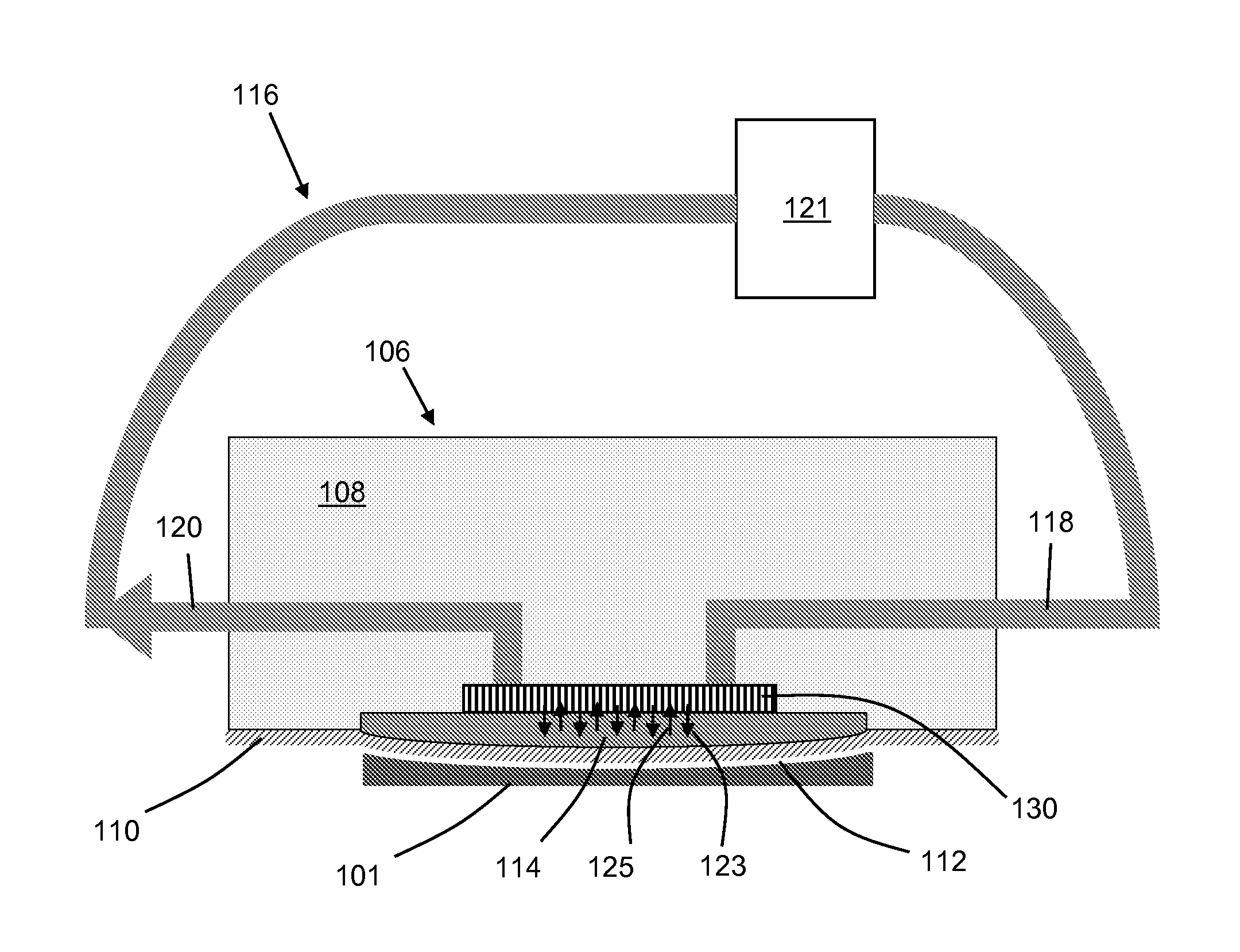

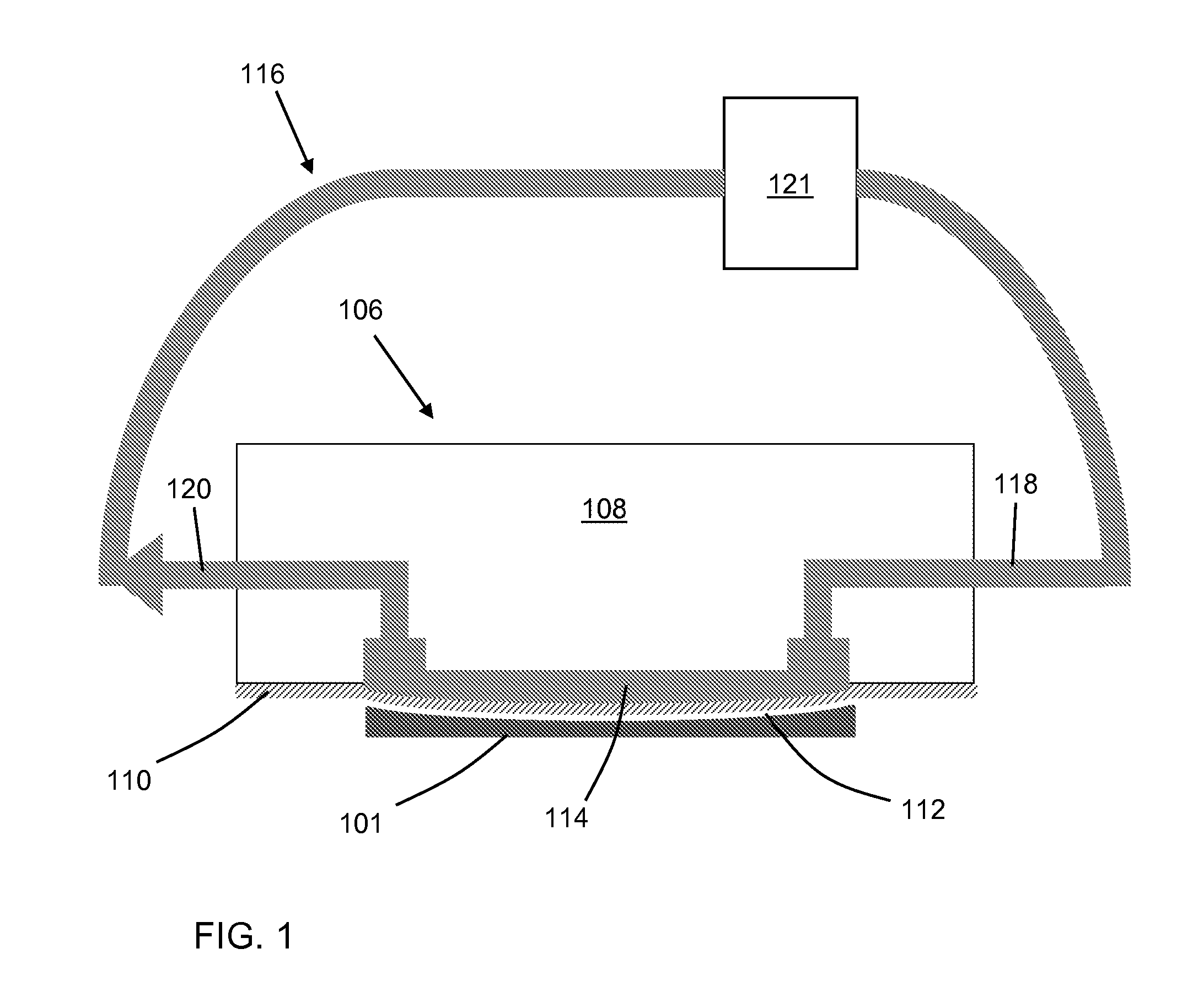

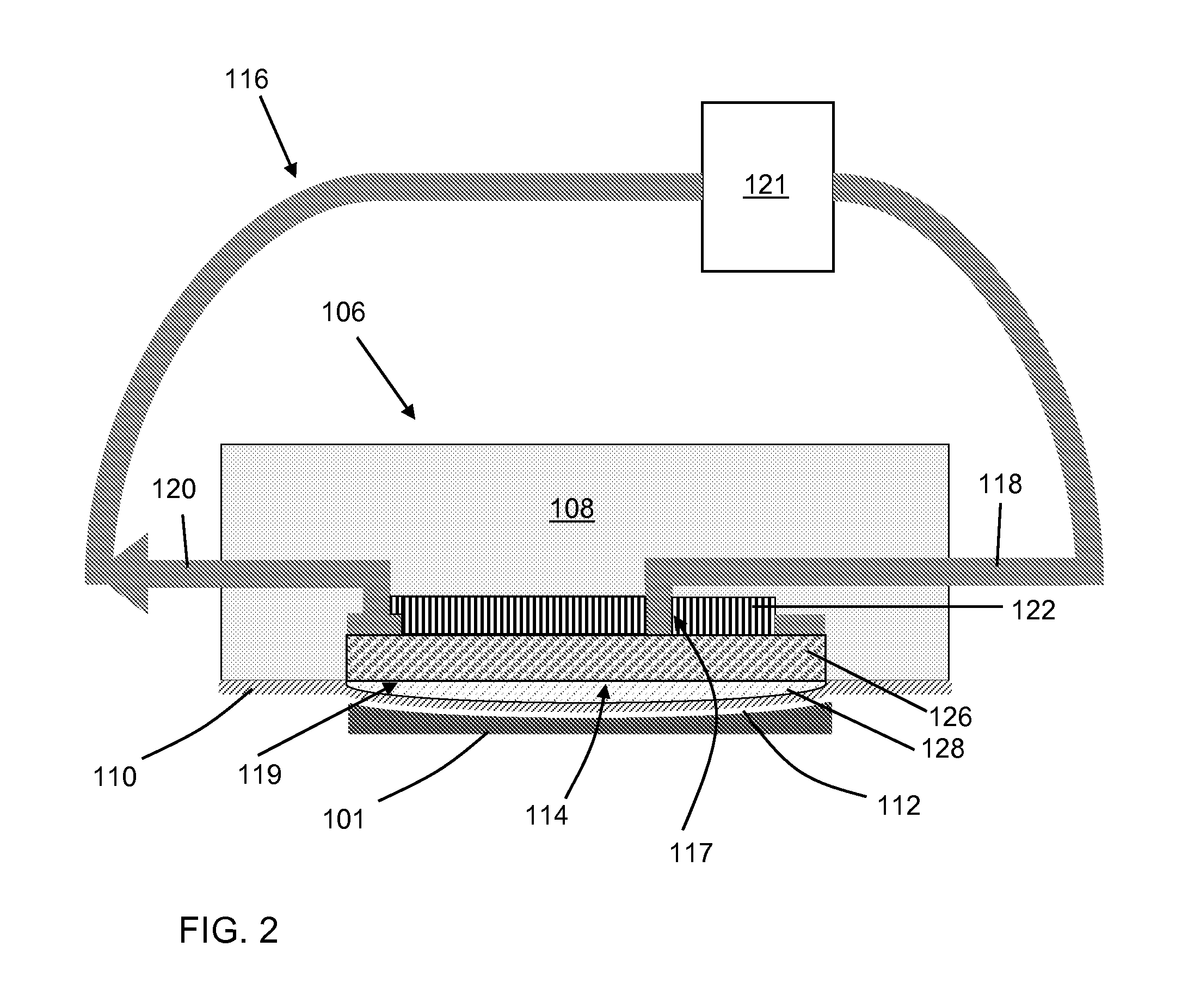

[0021]Referring to the drawings, embodiments of the structure and method according to the disclosure are shown in FIGS. 1-3.

[0022]Turning to FIG. 1, a detailed view of an embodiment of heat sink 106 according to embodiments of the invention is shown. Heat sink 106 includes a manifold block 108, which may be copper. In various other embodiments, manifold block 108 may be aluminum, stainless steel, plastic, ceramic and / or may be plated with various materials, including but not limited to nickel, gold, and silver. A compliant foil 110 is affixed to manifold block 108, forming an interface 112 between heat sink 106 and a surface of IC chip 101. Compliant foil 110 is thin, and made of a thermally conductive material. Foil 110 may be made of beryllium copper (BeCu) and may measure approximately 75 μm in thickness, however, in various alternative embodiments, foil 110 may be made of other conductive materials including but not limited to copper, indium, gold, silver, and stainless steel, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com