Diesel fuel composition

a technology of diesel fuel and composition, applied in the direction of biofuels, biofeedstocks, fuels, etc., can solve the problems of reducing the heat generation capacity of the diesel engine, reducing the regenerative ability of the dpf, and not being able to heat the diesel particulate filter (dpf) to high temperature, so as to reduce the formation of sludg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0047]Next, the present invention will be explained in further detail based on Examples; however, the present invention is not to be limited thereto.

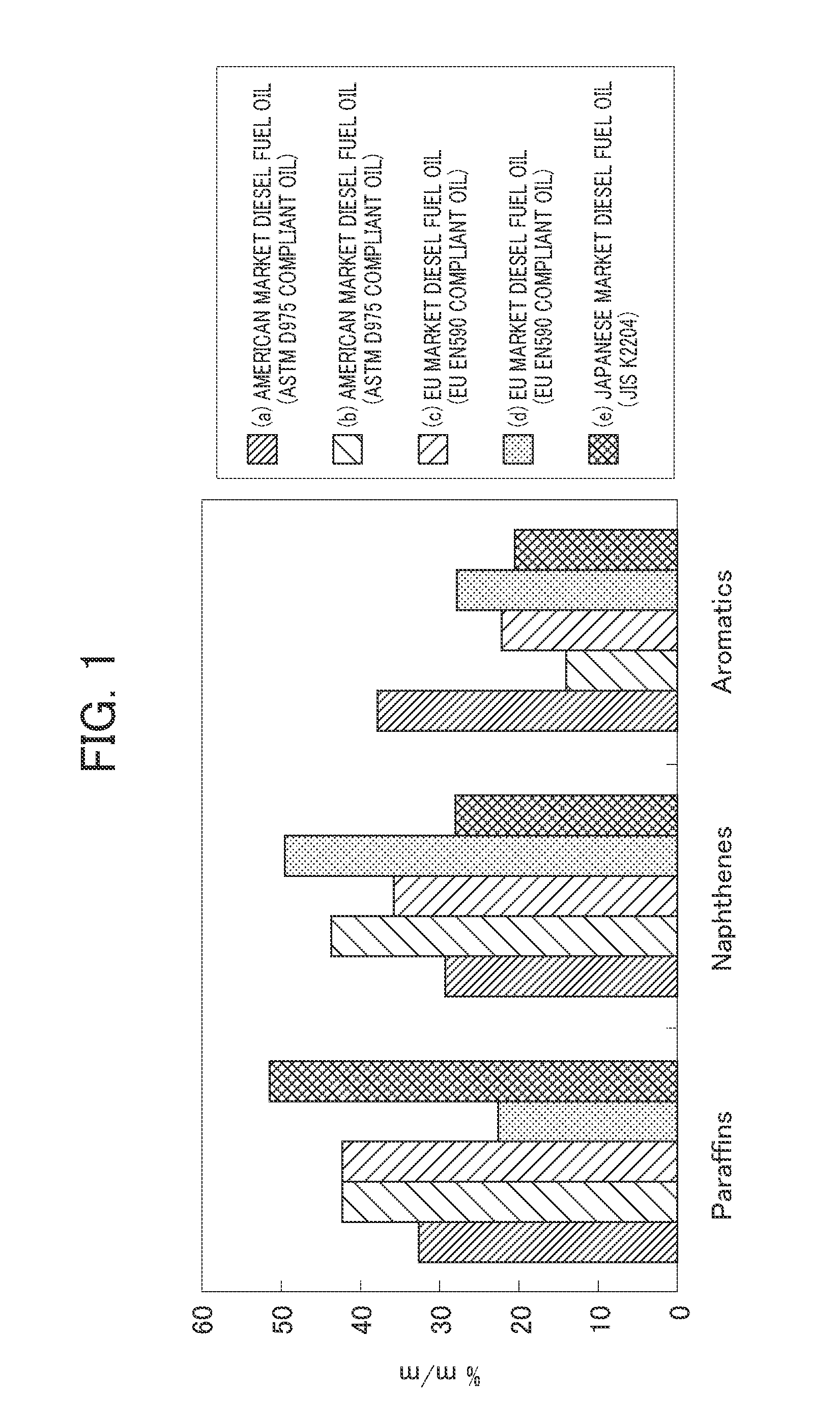

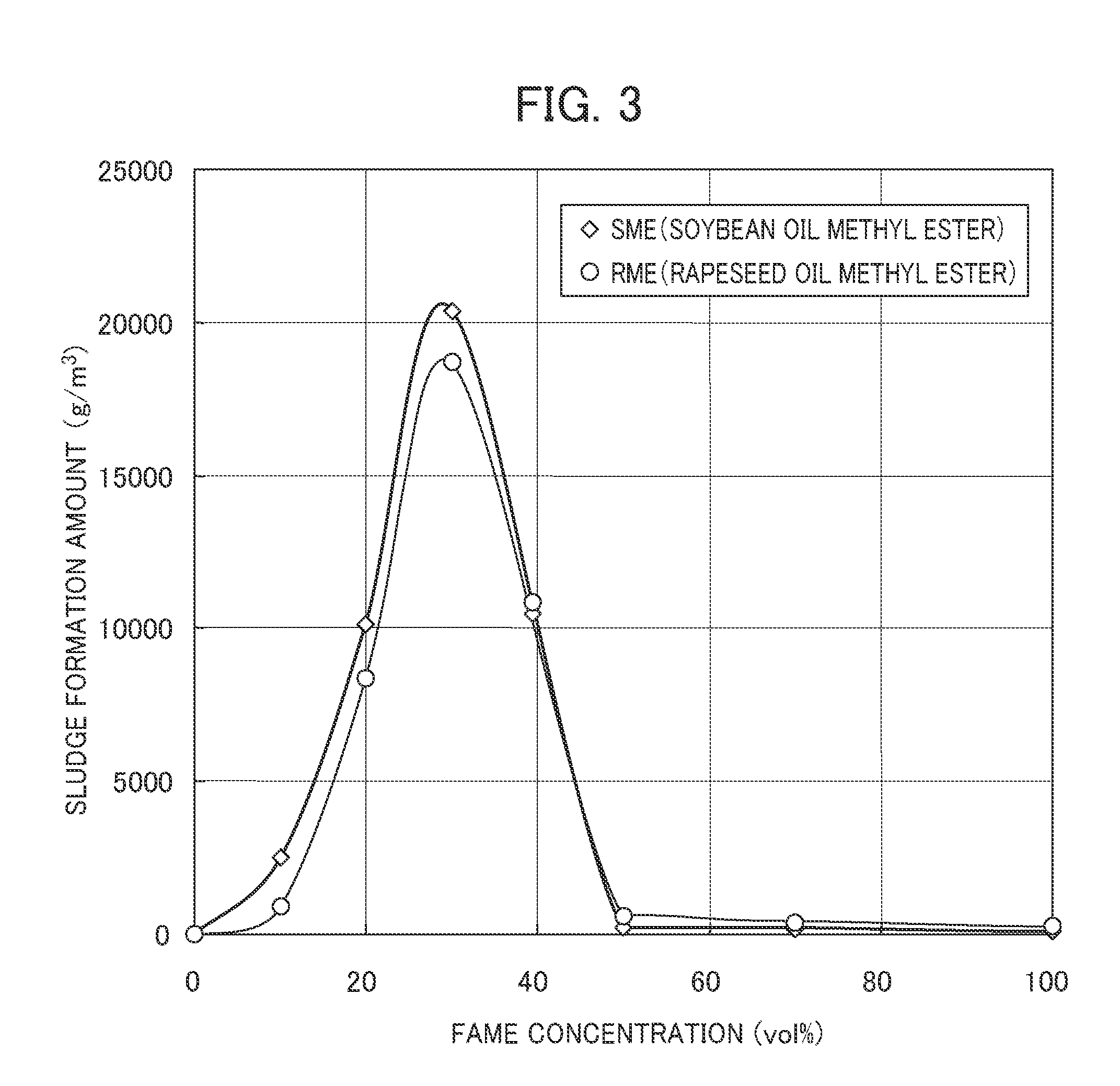

Investigation of Content Percentage of Aromatic Component and Paraffin Component

[0048]Using tetralin (manufactured by Wako Pure Chemical Industries, Ltd., grade 1 tetralin) as a substitute for the aromatic component, and using cetane (manufactured by Kanto Koatsu Kagaku Co., Ltd., reference fuel cetane) as a substitute for the paraffin component, an artificial diesel fuel oil was prepared in which the tetralin and cetane were blended at predetermined proportions. Methyl linoleate or methyl linolenic acid were respectively added to the artificial diesel fuel oil thus prepared (B20 only methyl oleate was also added), and a diesel fuel compositions having an added concentration of these fatty acid methyls of 10% by volume, 20% by volume and 30% by volume were produced.

[0049]Herein, the three main components of naphthene component, paraffin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine value | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com