[0008]The invention provides an exhaust gas heat recovery unit and exhaust gas heat

recovery method that makes it possible to recover heat efficiently by promptly heating a working fluid at a heater portion in a short time using exhaust gas in the case of cold starting of an engine.

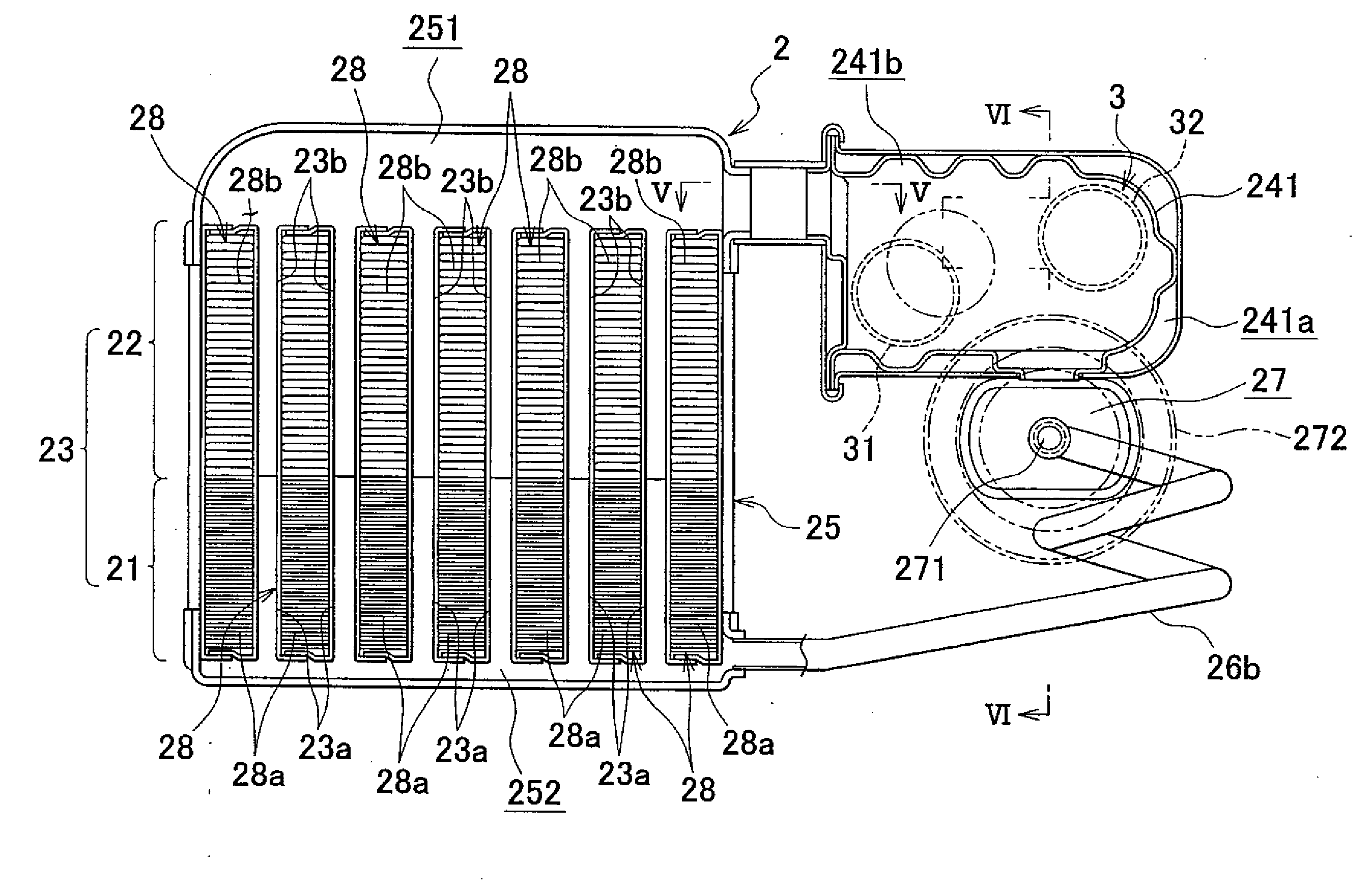

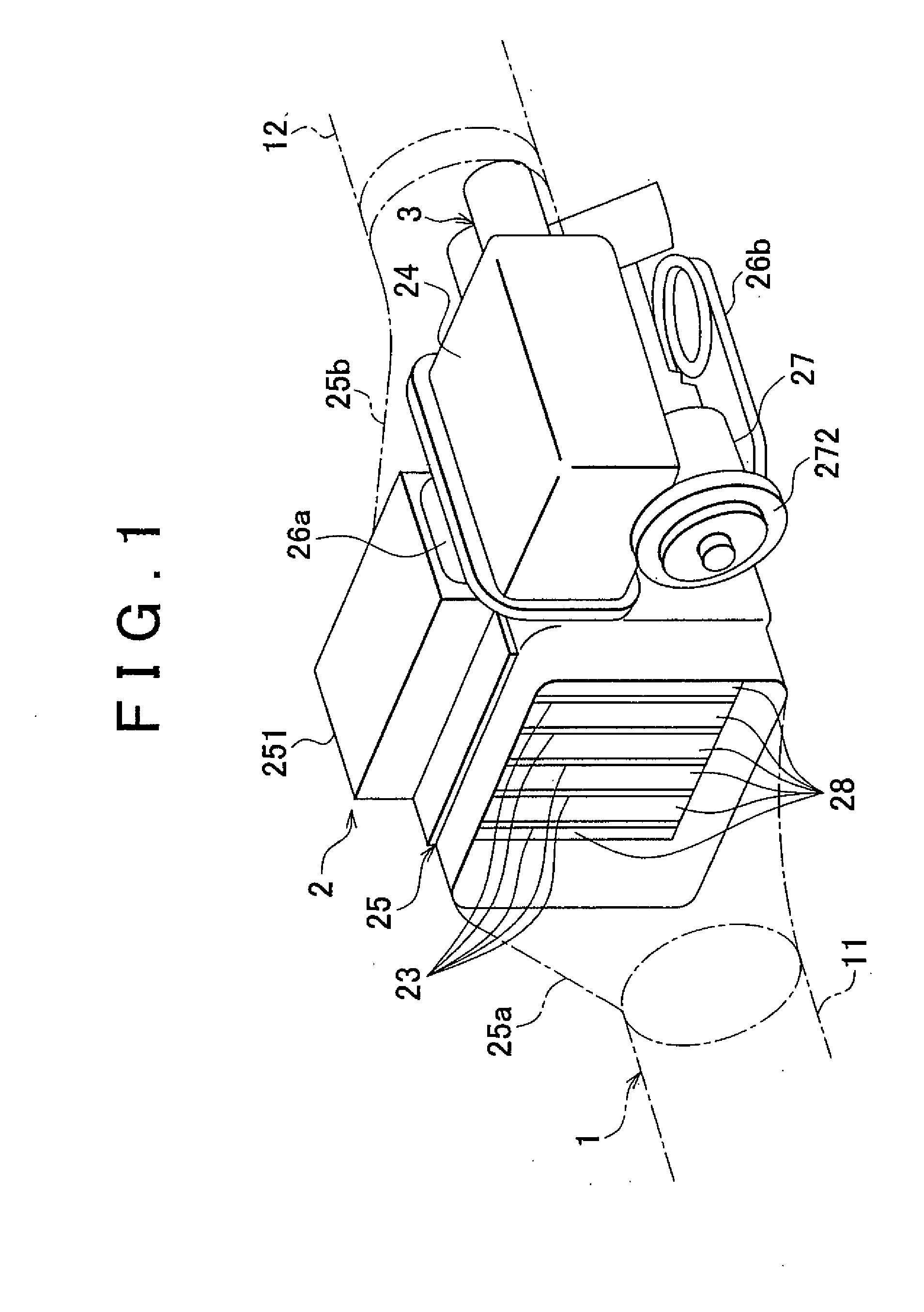

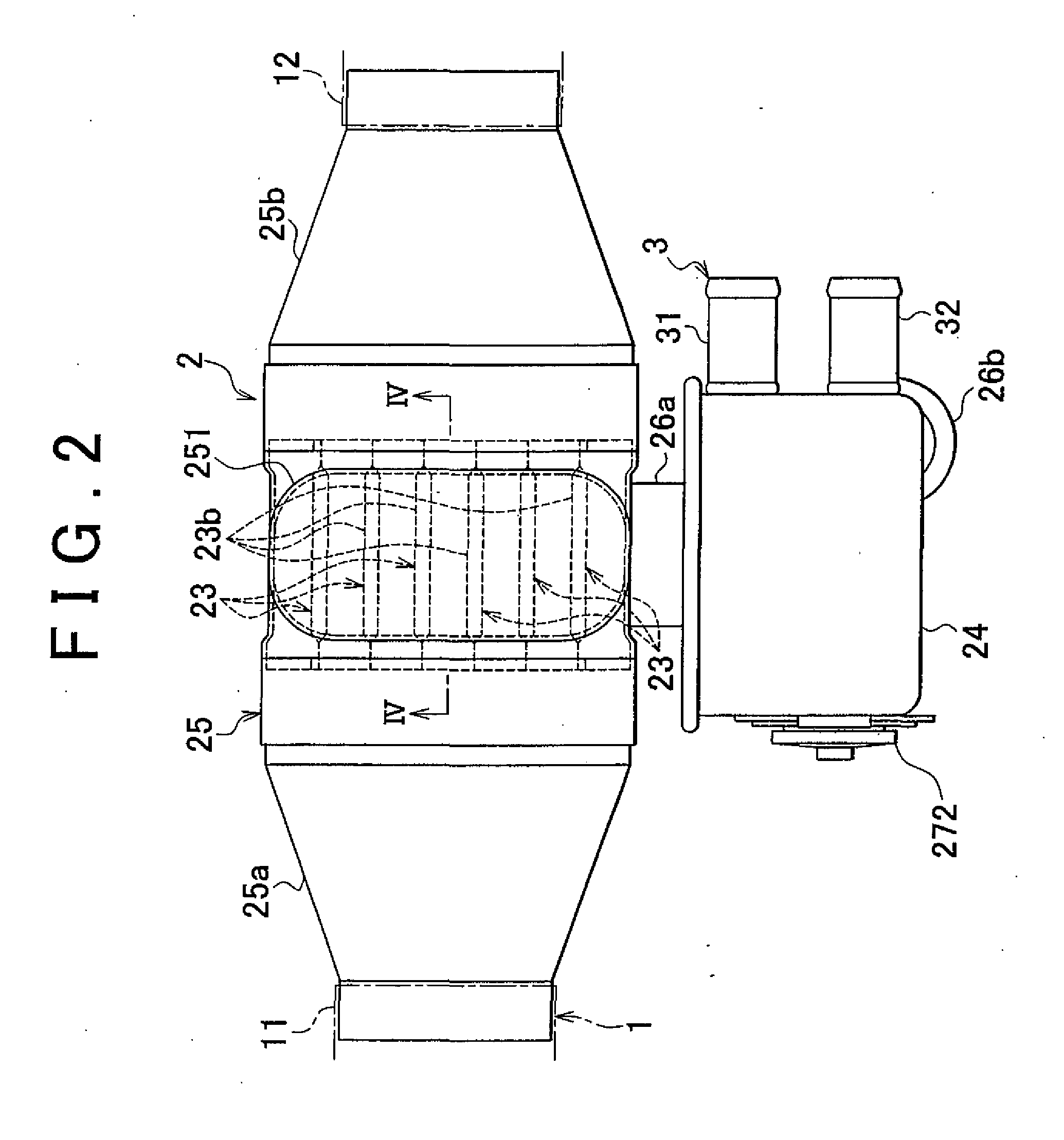

[0010]With this structure, the amount of heat that the fins on the heater portion receive is larger than the amount of heat that the fins on the evaporator portion receive. Therefore, in the case where the exhaust gas heat recovery unit is exposed to an ambient temperature of equal to or lower than the freezing temperature of the working fluid, for example, in the case of cold starting of the engine, a sufficient amount of heat of the exhaust gas is applied to the heater portion that stores the working fluid, and the working fluid in the heating portion is promptly heated by the sufficient amount of heat received from the exhaust gas. As a result, it is possible to smoothly circulate the working fluid to efficiently recover the heat with the use of the exhaust gas heat recovery unit, in the case of cold starting of the engine.

[0011]In addition, most part of the predetermined amount of heat received from the exhaust gas is covered by the heat received by the fins on the outer periphery of the heater portion due to the small

pitch of the fins. Further, an increase in exhaust gas flow resistance due to the above-described small pitch is offset by setting the pitch of the fins on the outer periphery of the evaporator portion to a large pitch. As a result, it is possible to suppress an increase in

back pressure, which is caused on the downstream side in the exhaust gas flow direction due to provision of the exhaust gas heat recovery unit.

[0014]With this structure, the pitch of the fins on the outer periphery of the heater portion of the heat pipe is set in such a manner that the temperature of the working fluid, which is exposed to an ambient temperature of equal to or lower than the freezing temperature of the working fluid at cold starting time of the engine, is increased to a temperature equal to or higher than the freezing temperature by the amount Qex of heat that is received from the exhaust gas within the predetermined period from cold starting of the engine. Therefore, in the case where the exhaust gas heat recovery unit is exposed to an ambient temperature of equal to or lower than the freezing temperature of the working fluid, for example, in the case of cold starting of the engine, a sufficient amount of heat of the exhaust gas is applied to the heater portion that stores the working fluid, and the working fluid in the heating portion is promptly heated by the sufficient amount of heat received from the exhaust gas. As a result, it is possible to smoothly circulate the working fluid to efficiently recover the heat with the use of the exhaust gas heat recovery unit in the case of cold starting of the engine.

[0016]The pitch of the fins on the outer periphery of the heater portion of the heat pipe is set in such a manner that the temperature of the working fluid, which is exposed to an ambient temperature of equal to or lower than the freezing temperature of the working fluid at cold starting time of the engine, is increased to a temperature equal to or higher than the freezing temperature by the amount Qex of heat that is received from the exhaust gas within the predetermined period from cold starting of the engine. Therefore, in the case where the exhaust gas heat recovery unit is exposed to an ambient temperature of equal to or lower than the freezing temperature of the working fluid, in the case of cold starting of the engine, a sufficient amount of heat of the exhaust gas is applied to the heater portion that stores the working fluid, and the heat of the exhaust gas applied to the heater portion is sufficiently transferred to the working fluid in the fluid passage. Thus, the working fluid in the heating portion and the working fluid in the fluid passage are promptly heated by the sufficient amount of heat received from the exhaust gas. As a result, it is possible to smoothly circulate the working fluid to efficiently recover the heat with the use of the exhaust gas heat recovery unit in the case of cold starting of the engine.

[0018]With this structure, an increase in the exhaust gas flow resistance, which is caused due to the small pitch of the fins on the outer periphery of the heater portion, is offset by setting the pitch of the fins on the outer periphery of the evaporator to a large pitch. Therefore, it is possible to efficiently suppress an increase in

back pressure, which is caused on the downstream side in the exhaust gas flow direction due to provision of the exhaust gas heat recovery unit.

Login to View More

Login to View More  Login to View More

Login to View More