Catalyst, production process therefor and use thereof

a catalyst and catalyst technology, applied in the field of catalysts, processes for producing catalysts, can solve the problems of noble metals used on the cathode surface, high cost and limited amount of platinum, and the use of long-term durability in these applications, so as to achieve high oxygen reduction ability, not corroded, and high performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

1. Preparation of Catalyst

[0117]Niobium (IV) oxide (NbO2) weighing 2.60 g (21 mmol) was mixed with 600 mg (50 mmol) of carbon (Vulcan 72 manufactured by Cabot Corporation) and was sufficiently crushed. The resultant powder mixture was heat treated in a tubular furnace under a nitrogen atmosphere at 1600° C. for 1 hour to give 2.55 g of niobium carbonitride.

[0118]The niobium carbonitride in an amount of 2.00 g was heated in the tubular furnace at 800° C. for 1 hour while passing an argon gas containing 1% by volume of oxygen gas. As a result, 2.15 g of niobium oxycarbonitride (hereinafter, also the catalyst (1)) was obtained.

[0119]The results of elemental analysis of the catalyst (1) are shown in Table 1. In the niobium oxycarbonitride (NbCxNyOz), x, y and z were 0.52, 0.43 and 0.78 respectively, x+y+z was 1.73, and 4x+3y+2z was 4.93.

2. Production of Fuel Cell Electrode

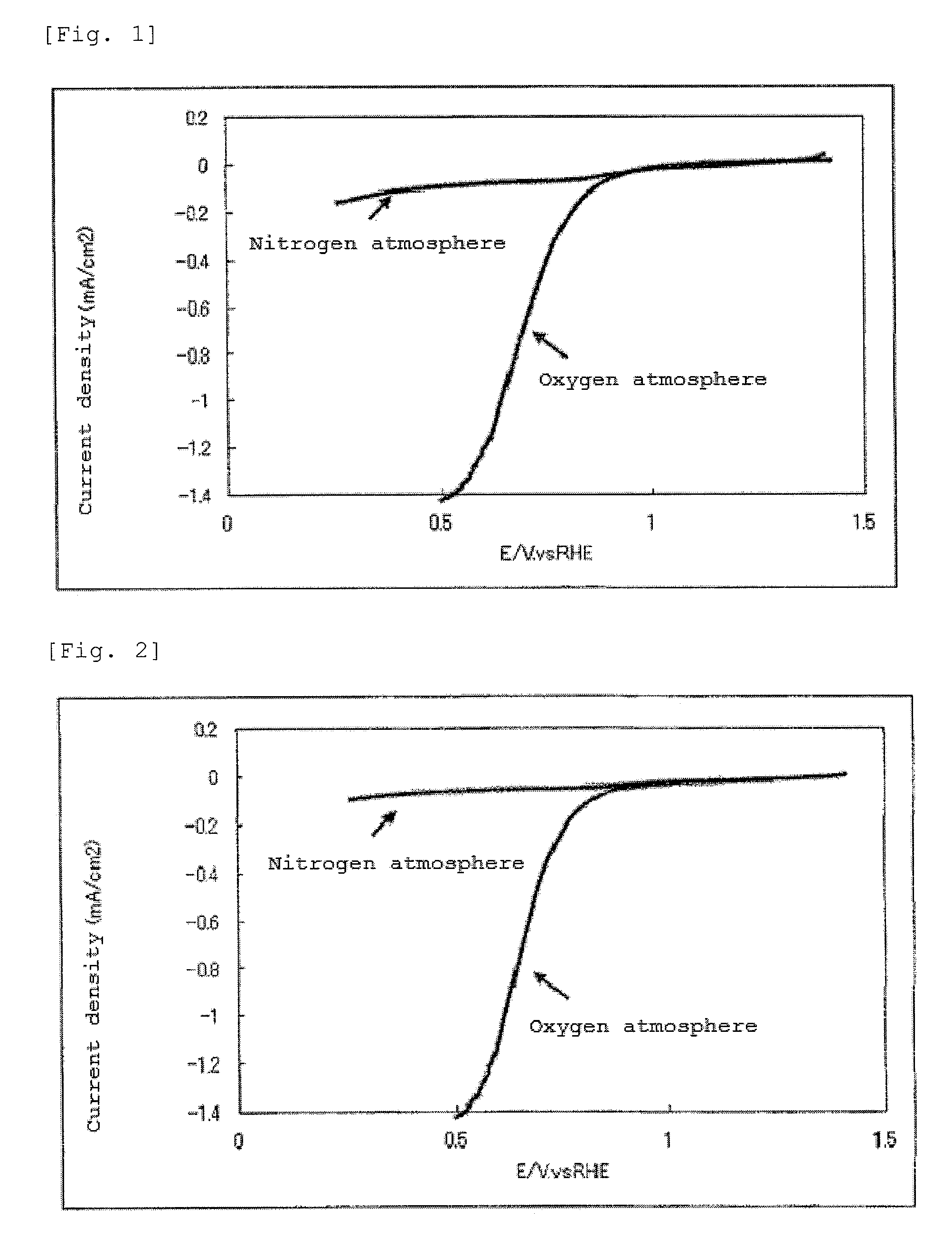

[0120]The oxygen reducing ability was determined in the following manner. The catalyst (1) in an amount of 0.095 g a...

example 2

1. Preparation of Catalyst

[0133]The procedures in Example 1 were repeated, except that the amount of carbon was changed from 600 mg to 480 mg (40 mmol), thereby producing 1.83 g of niobium carbonitride. The niobium carbonitride in an amount of 1.02 g was heated to give 1.09 g of niobium oxycarbonitride (hereinafter, also the catalyst (2)).

[0134]The results of elemental analysis of the catalyst (2) are shown in Table 1. In the niobium oxycarbonitride (NbCxNyOz), x, y and z were 0.32, 0.44 and 0.78 respectively, x+y+z was 1.54, and 4x+3y+2z was 4.16.

2. Production of Fuel Cell Electrode

[0135]A fuel cell electrode (2) was produced in the same manner as in Example 1, except that the catalyst (2) was used.

3. Evaluation of Oxygen Reducing Ability

[0136]The fuel cell electrode (2) was evaluated for catalytic performance (oxygen reducing ability) as described in Example 1.

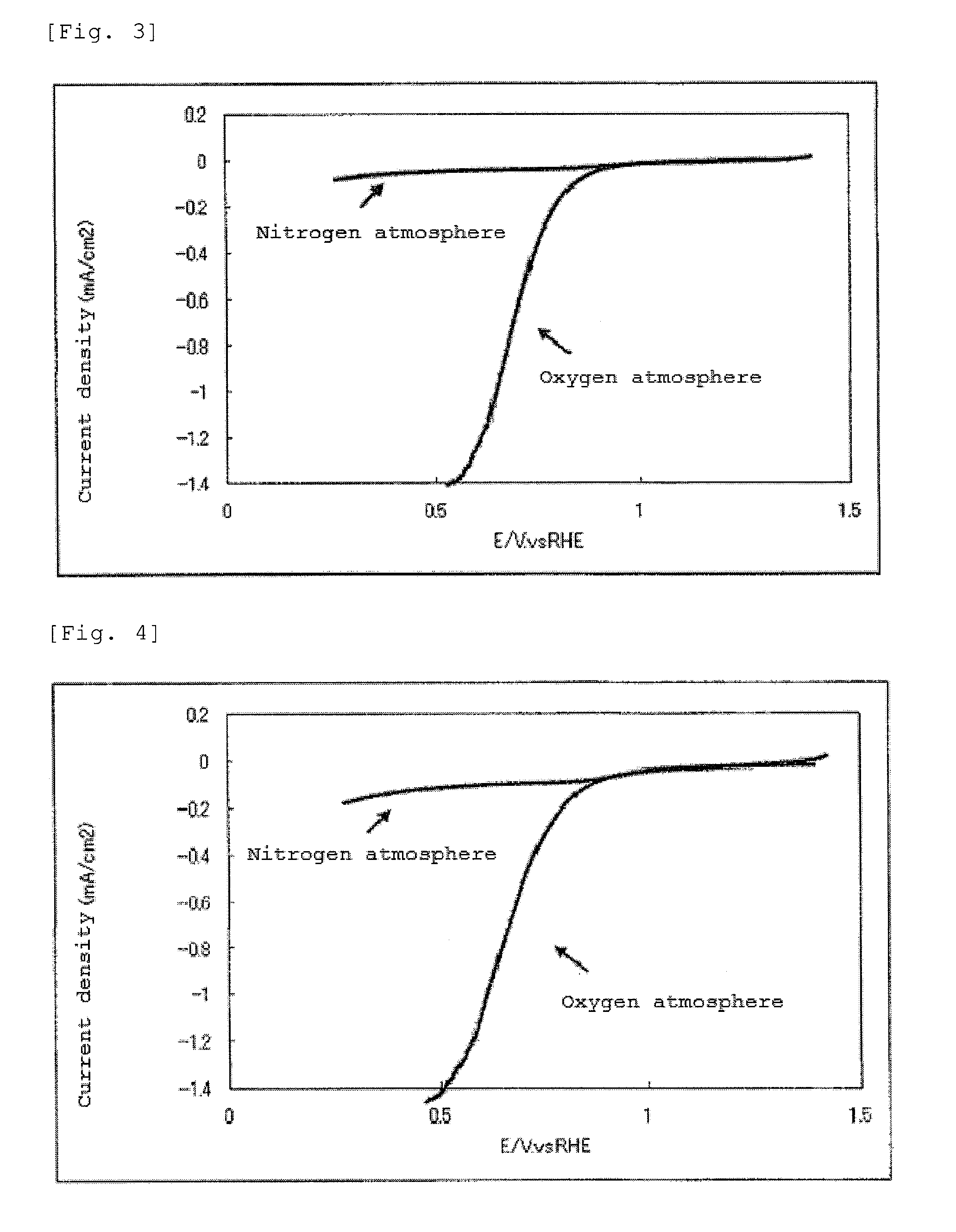

[0137]The current-potential curve recorded during the measurement is shown in FIG. 2.

[0138]Table 2 shows the evaluation re...

example 3

1. Preparation of Catalyst

[0140]The procedures in Example 1 were repeated, except that the amount of carbon was changed from 600 mg to 730 mg (61 mmol), thereby producing 1.67 g of niobium carbonitride. The niobium carbonitride in an amount of 1.10 g was heated to give 1.12 g of niobium oxycarbonitride (hereinafter, also the catalyst (3)).

[0141]The results of elemental analysis of the catalyst (3) are shown in Table 1. In the niobium oxycarbonitride (NbCxNyOz), x, y and z were 0.55, 0.41 and 0.77 respectively, x+y+z was 1.73, and 4x+3y+2z was 4.97.

2. Production of Fuel Cell Electrode

[0142]A fuel cell electrode (3) was produced in the same manner as in Example 1, except that the catalyst (3) was used.

3. Evaluation of Oxygen Reducing Ability

[0143]The fuel cell electrode (3) was evaluated for catalytic performance (oxygen reducing ability) as described in Example 1.

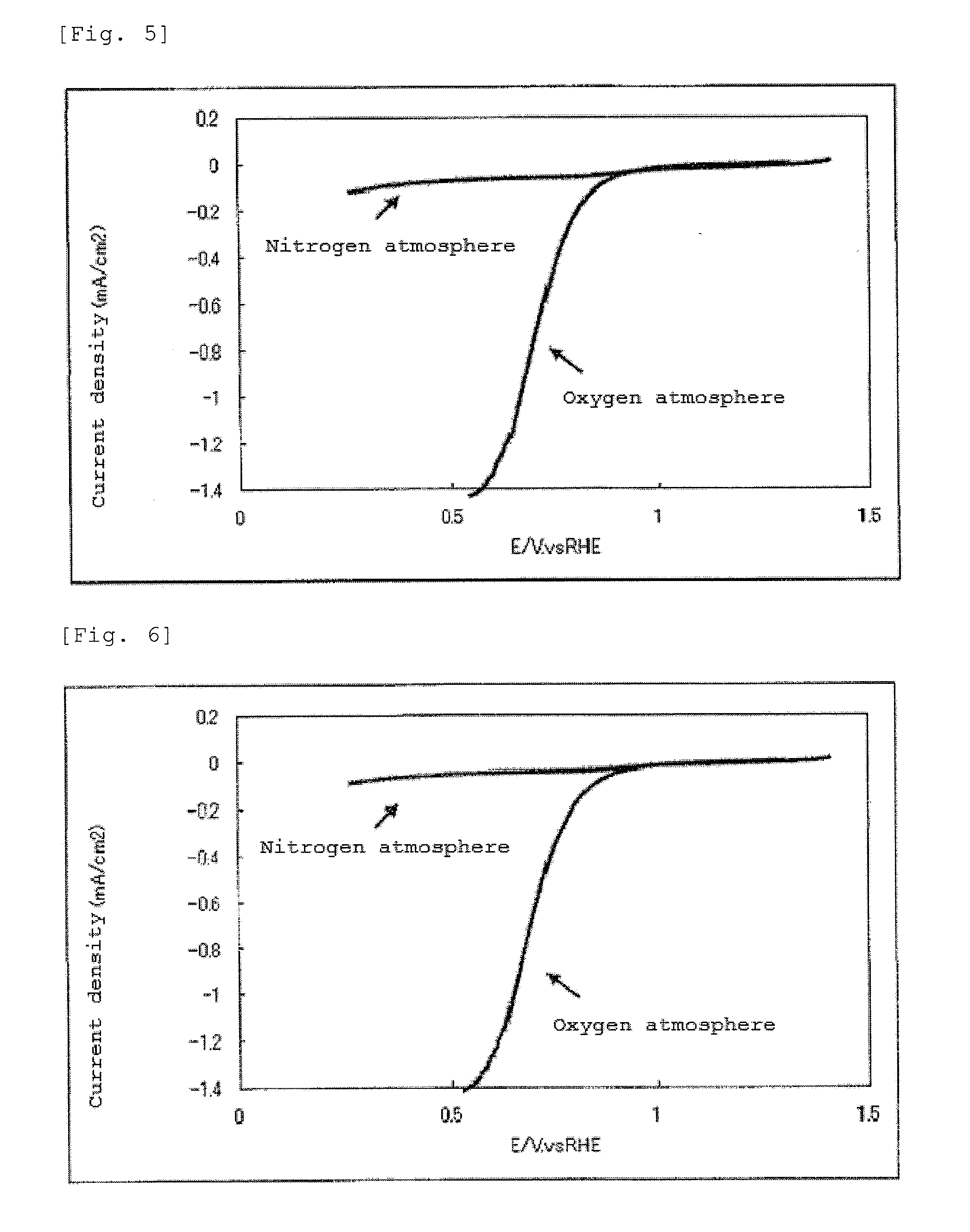

[0144]The current-potential curve recorded during the measurement is shown in FIG. 3.

[0145]Table 2 shows the evaluation re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Percent by volume | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com