Tactical firearm having heat shielding properties and improved gas energized cartridge feeding

a technology of heat shielding and tactical firearms, applied in the field of firearms, can solve the problems of pain or injury to the bare hands and arms of firearm users, excessive heating conditions, and rapid heat generation of handguard cars, so as to prevent rapid heat transfer and efficient heat conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

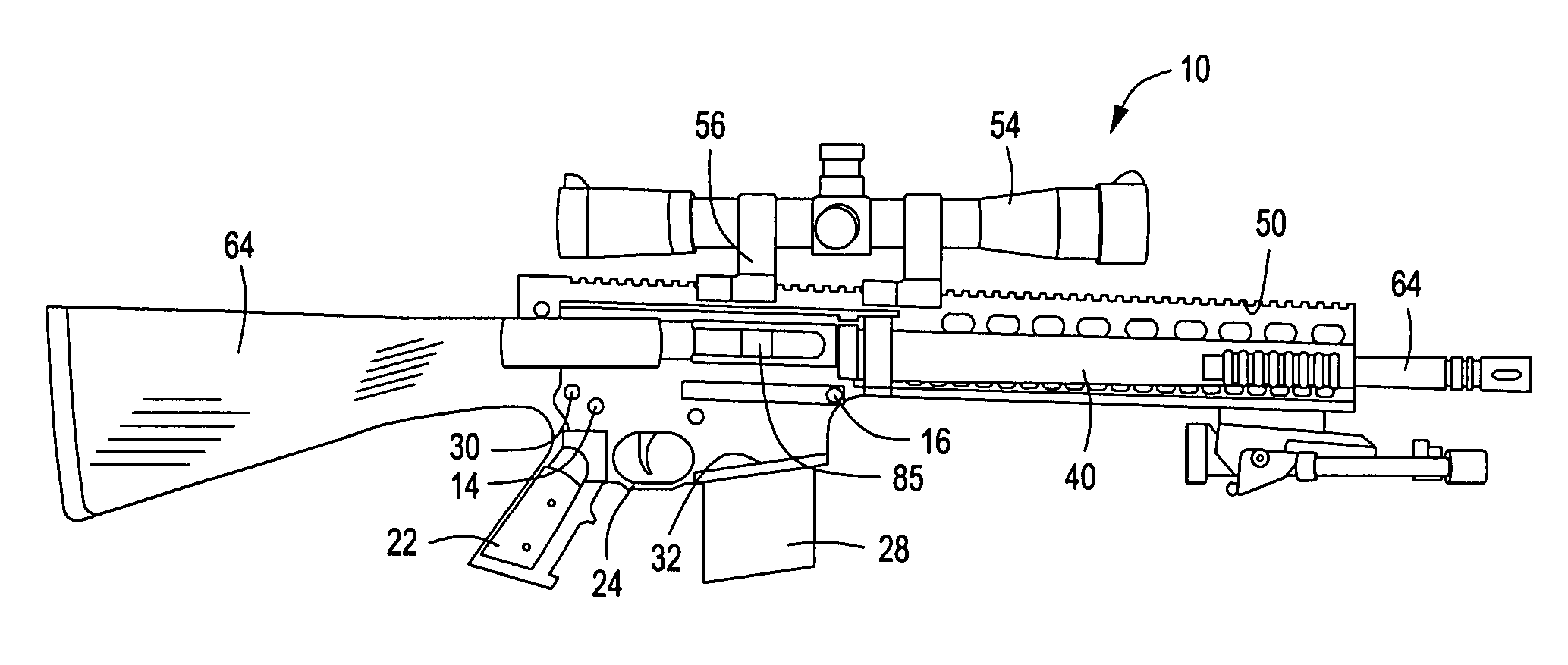

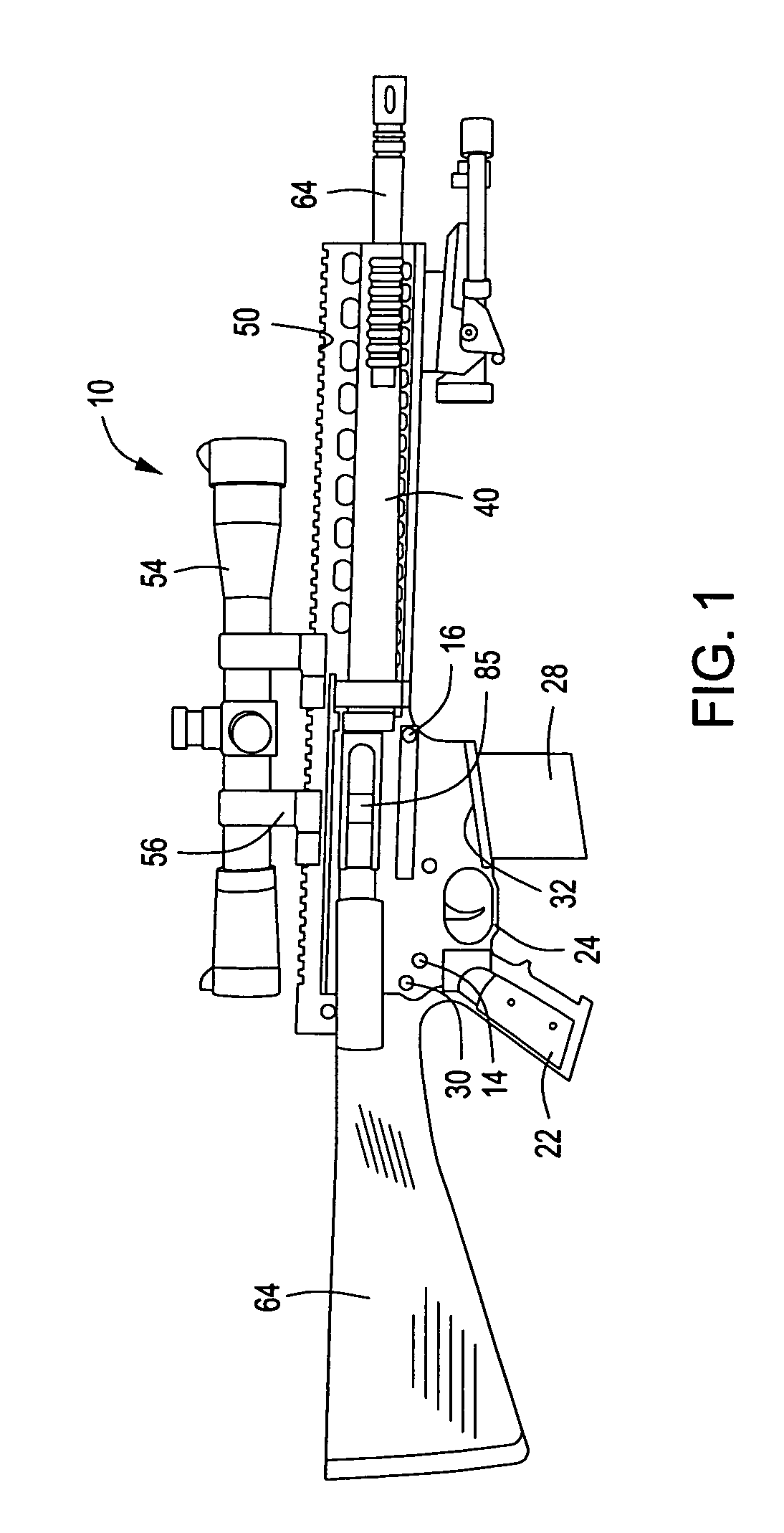

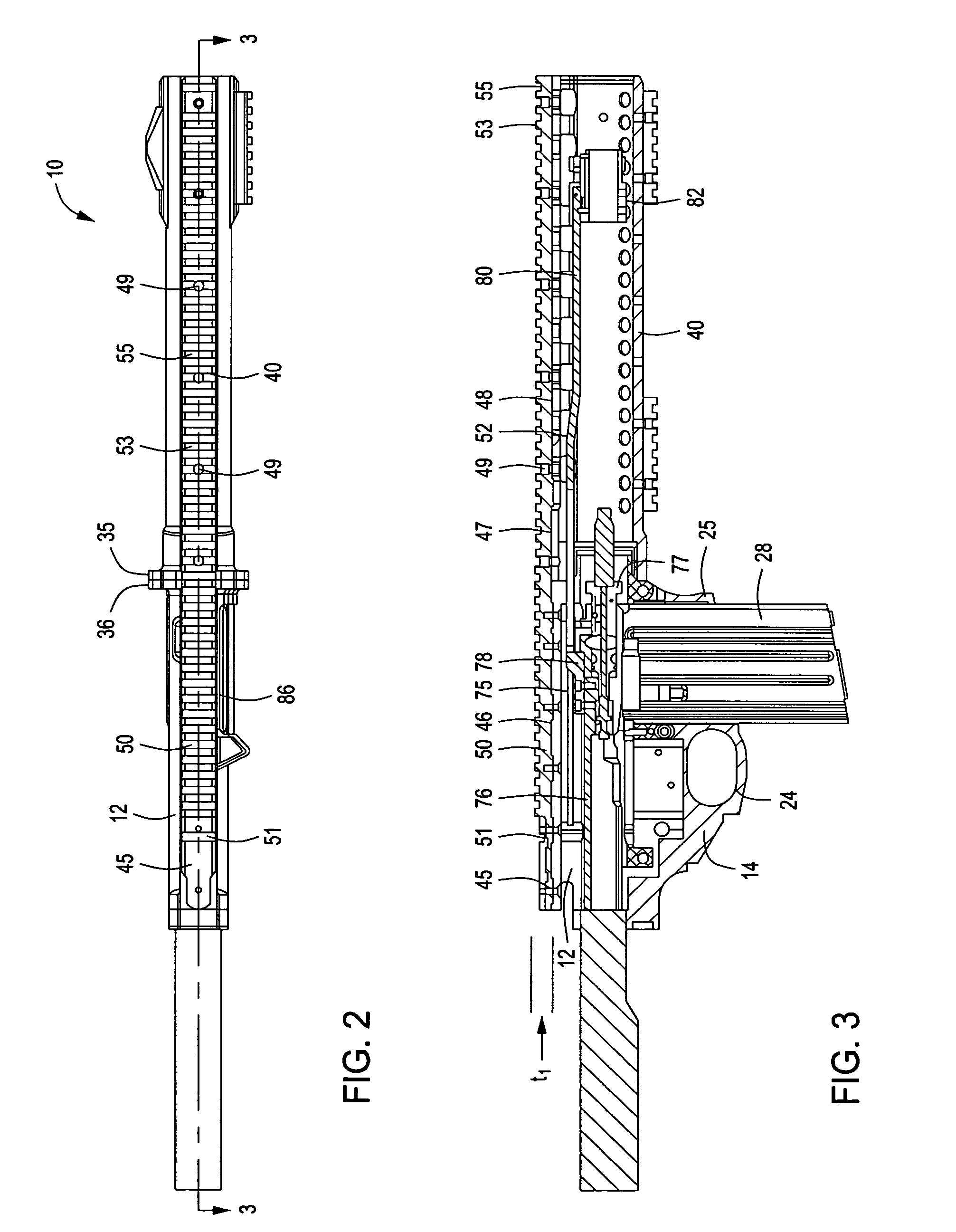

[0032]Referring now to the drawings and first to the elevational view of FIG. 1, there is shown a tactical firearm generally at 10 embodying the principles of the present invention. The firearm 10, is preferably in the form of a tactical rifle of relatively heavy bore, such as being chambered for the 7.62 mm United States Military cartridge, also referred to as the .308 caliber rifle cartridge. However, it should be borne in mind that the present invention is applicable to firearms of both lighter and heavier bore without departing from the spirit and scope of the invention. For purposes of simplicity, though the scope of this invention encompasses a wide range of firearm devices, the invention is referred to herein as a tactical rifle.

[0033]The tactical rifle 10 incorporates an upper receiver 12 to which a lower receiver 14 is pivotally mounted by means of a pivot pin 16 which extends through corresponding pivot openings of the lower receiver 14 and a pivot opening 18 of a downward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com