Closed-loop capillary solar photovoltaic thermoelectric plate

A solar photovoltaic and solar cell technology, applied in the field of solar photovoltaic thermal integration technology, can solve the problems of consuming energy consumption of fans or water pumps, and achieve the effects of reducing operating temperature, high heat transfer efficiency, and improving photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

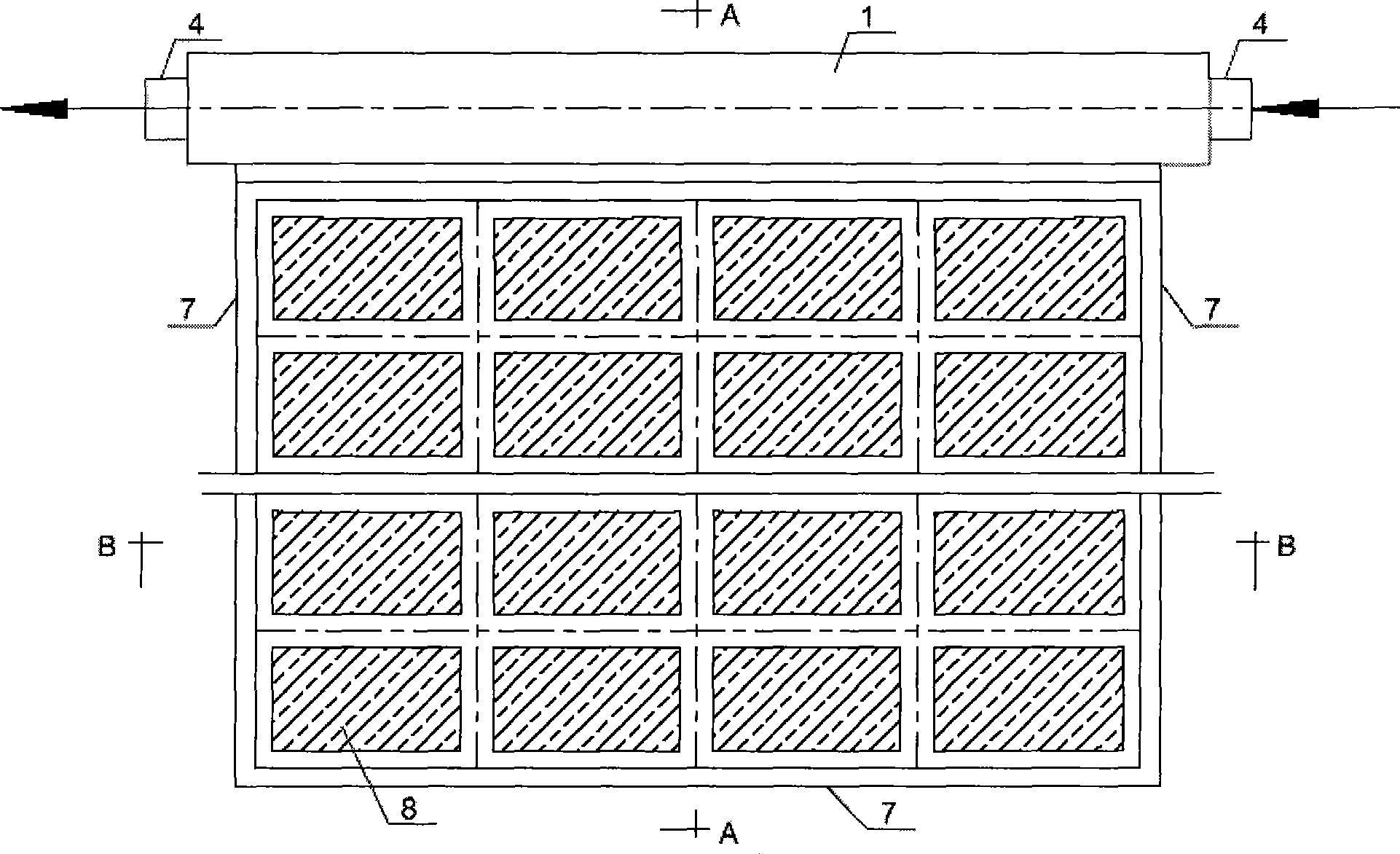

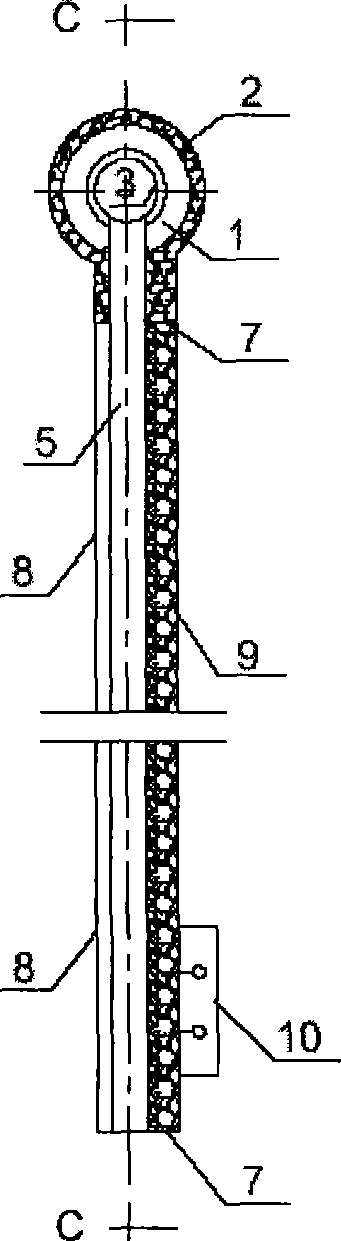

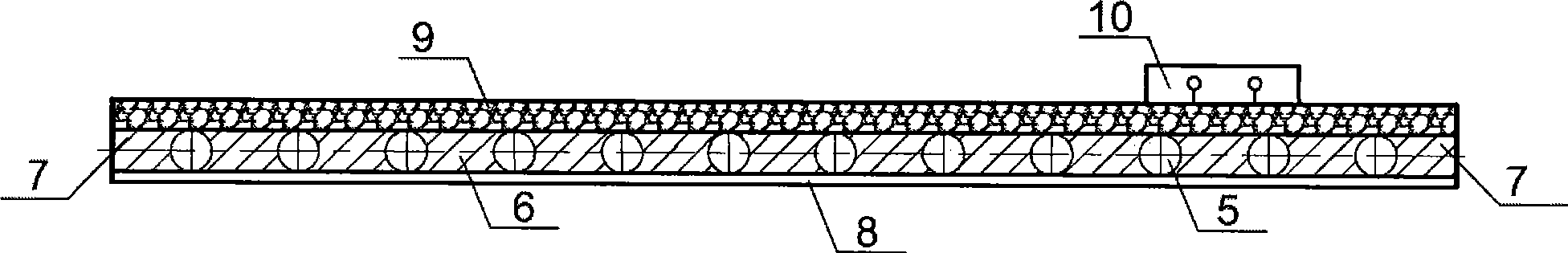

[0016] The specific embodiments of the present invention will be described in detail below with reference to the technical solutions and the accompanying drawings.

[0017] The closed-loop capillary metal tube solar photovoltaic thermoelectric panel of the present invention is composed of a header tube 1 , a fin tube 3 , a capillary metal tube 5 , a graphite heat conduction layer 6 , a metal frame 7 , a solar cell 8 and a thermal insulation layer 9 . The capillary metal tube 5 is composed of a U-shaped copper tube or other metal tube with an inner diameter of 2 to 5 mm; the finned tube 3 and the capillary metal tube 5 are welded to form a closed-loop pipeline; the capillary metal tube 5 is arranged in a loop in the heat collecting battery plate , which can be single or multiple; the capillary metal tube 5 and the graphite thermal conductive layer 6 constitute the substrate of the solar cell 8, the substrate is tightly connected with the solar cell 8, and the graphite thermal co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com