Non-destructive ultrasound inspection with coupling check

a coupling check and ultrasound technology, applied in the direction of instruments, magnetic property measurements, analysing solids using sonic/ultrasonic/infrasonic waves, etc., can solve the problems of increasing the size of the respective test probe, the inability of the additional transducer to generate a back-face echo, and the inability to reliably detect the position of the test tube. achieve the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

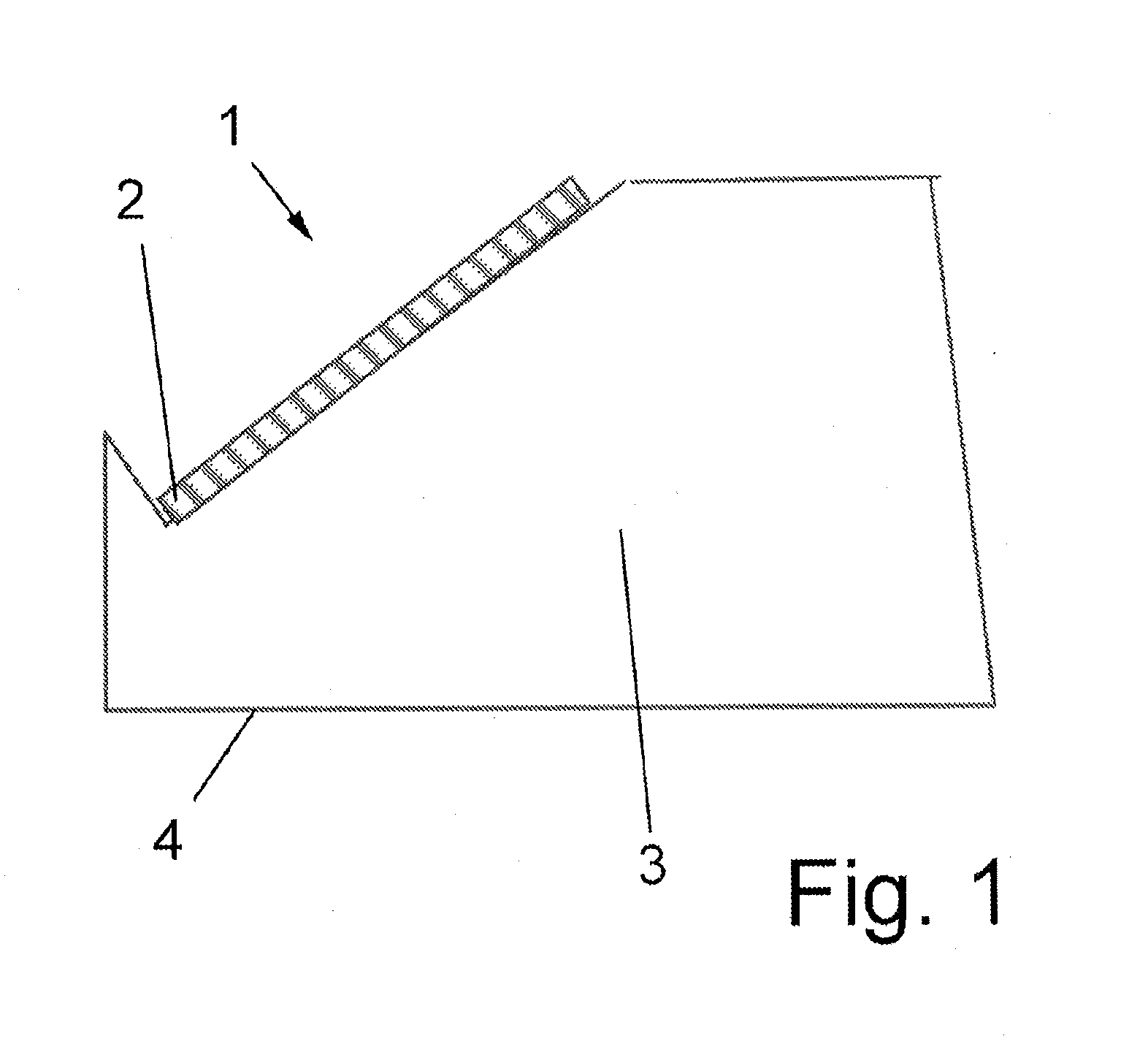

FIG. 1 schematically shows in a side view a typical structure of a phased array 1 used according to the invention with a plurality of individual ultrasonic transducers that can be controlled in a phase-accurate manner. The ultrasonic transducers 2 are disposed on a leading body 2 for coupling to the test piece 7 to be inspected. Depending on the desired transmission direction of the ultrasonic transducers 2, and depending on the shape of the surface of the test piece adjoining during the inspection, the leading body 3 can be designed to differ in the area of the contact surface 4 from the shape shown. The primary transmission direction can be changed to a certain extent by the selection of the phase shift between the ultrasonic pulses transmitted by the individual ultrasonic transducers 2. Thus, the phased array 1 can be used for carrying out the first and second test cycles.

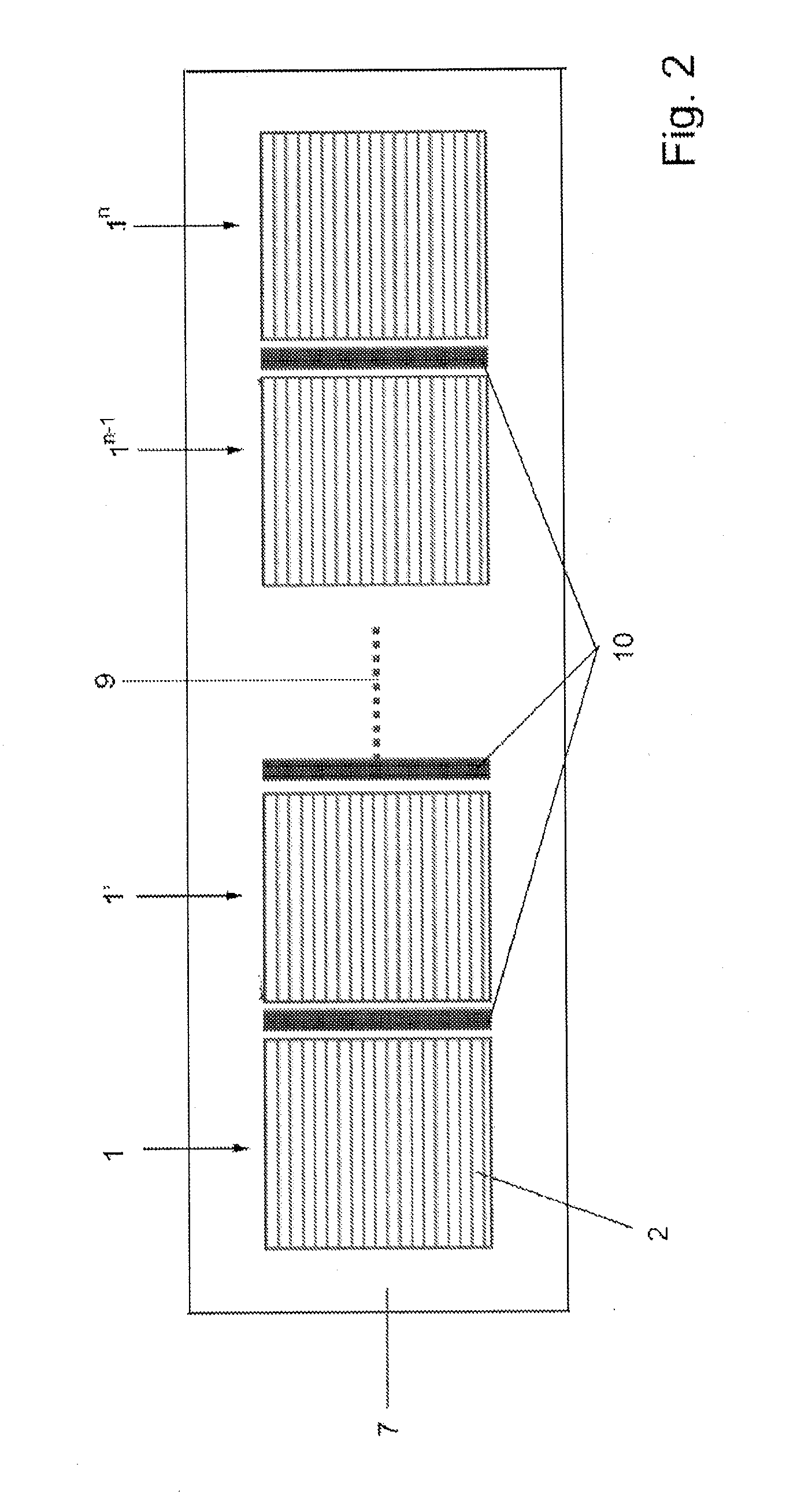

FIG. 2 shows in a schematic top view, by way of example, an arrangement according to the invention of several...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| phase-accurate | aaaaa | aaaaa |

| displacement | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com