Hydrogen storage device

a technology of hydrogen storage device and storage device, which is applied in the direction of liquid material, transportation and packaging, packaging goods types, etc., can solve the problems of reducing the efficiency of absorption, raising the temperature of the device, and affecting the absorption efficiency of hydrogen, so as to prevent distortion and deformation, the effect of ensuring the effective absorption and desorption of hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

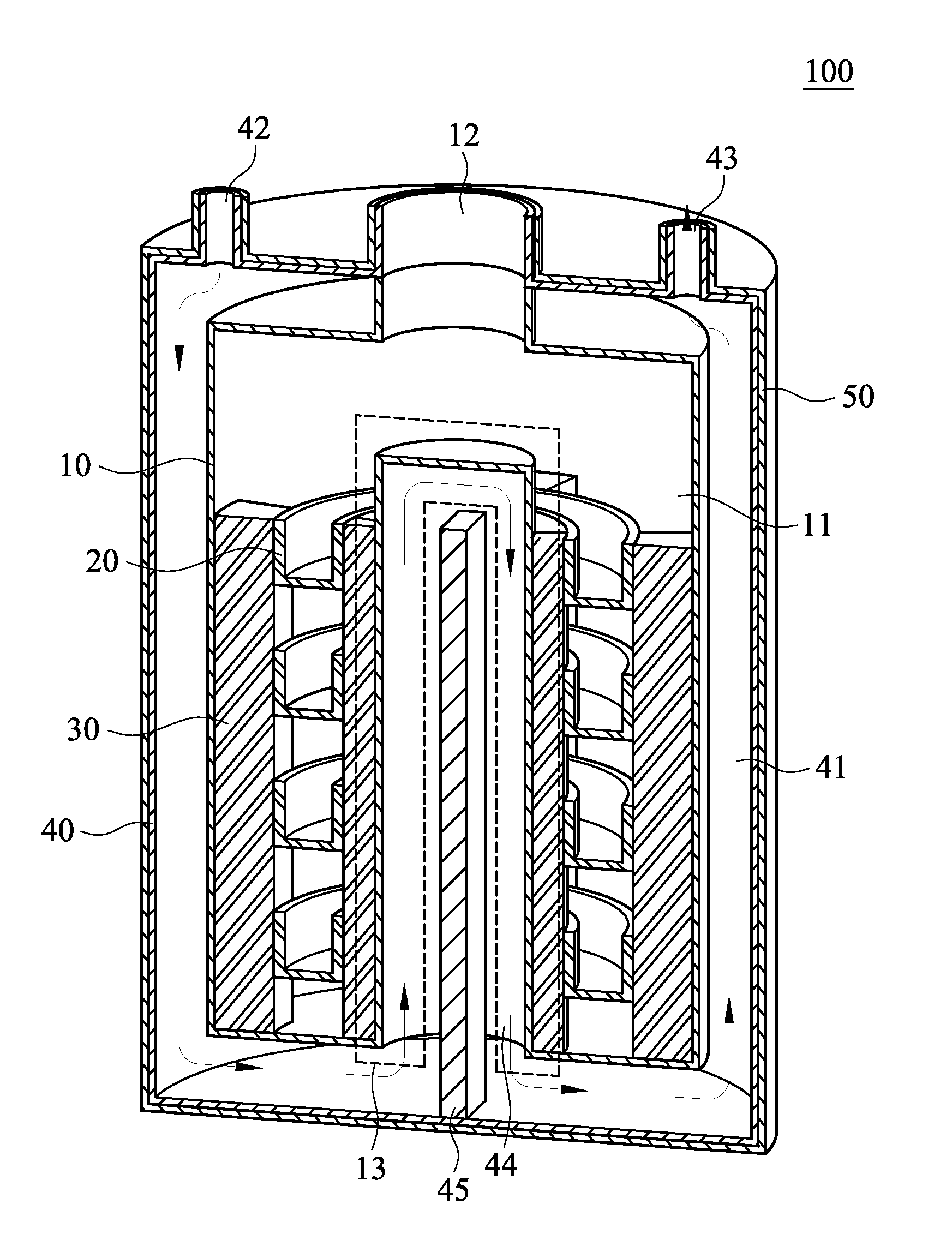

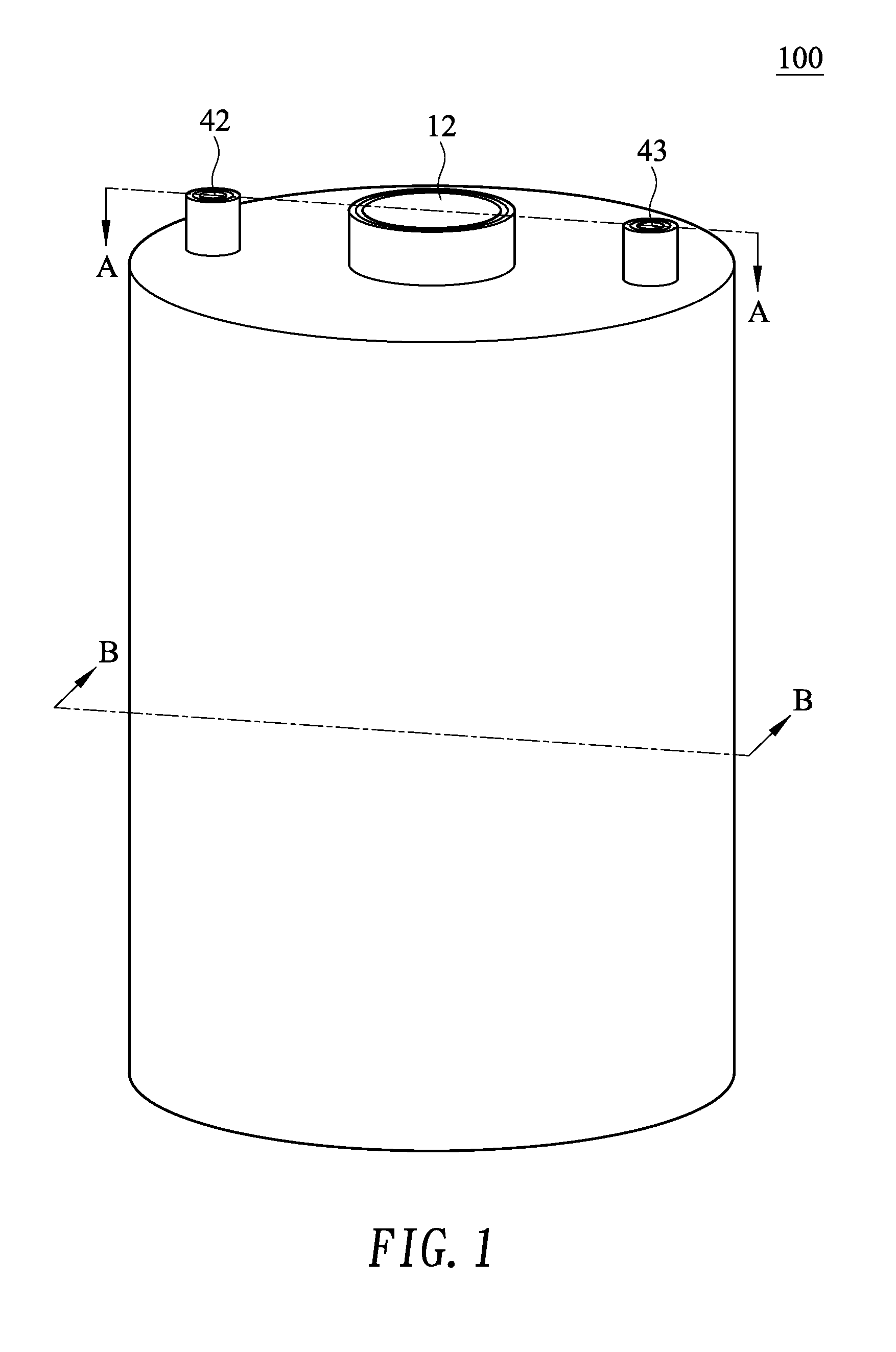

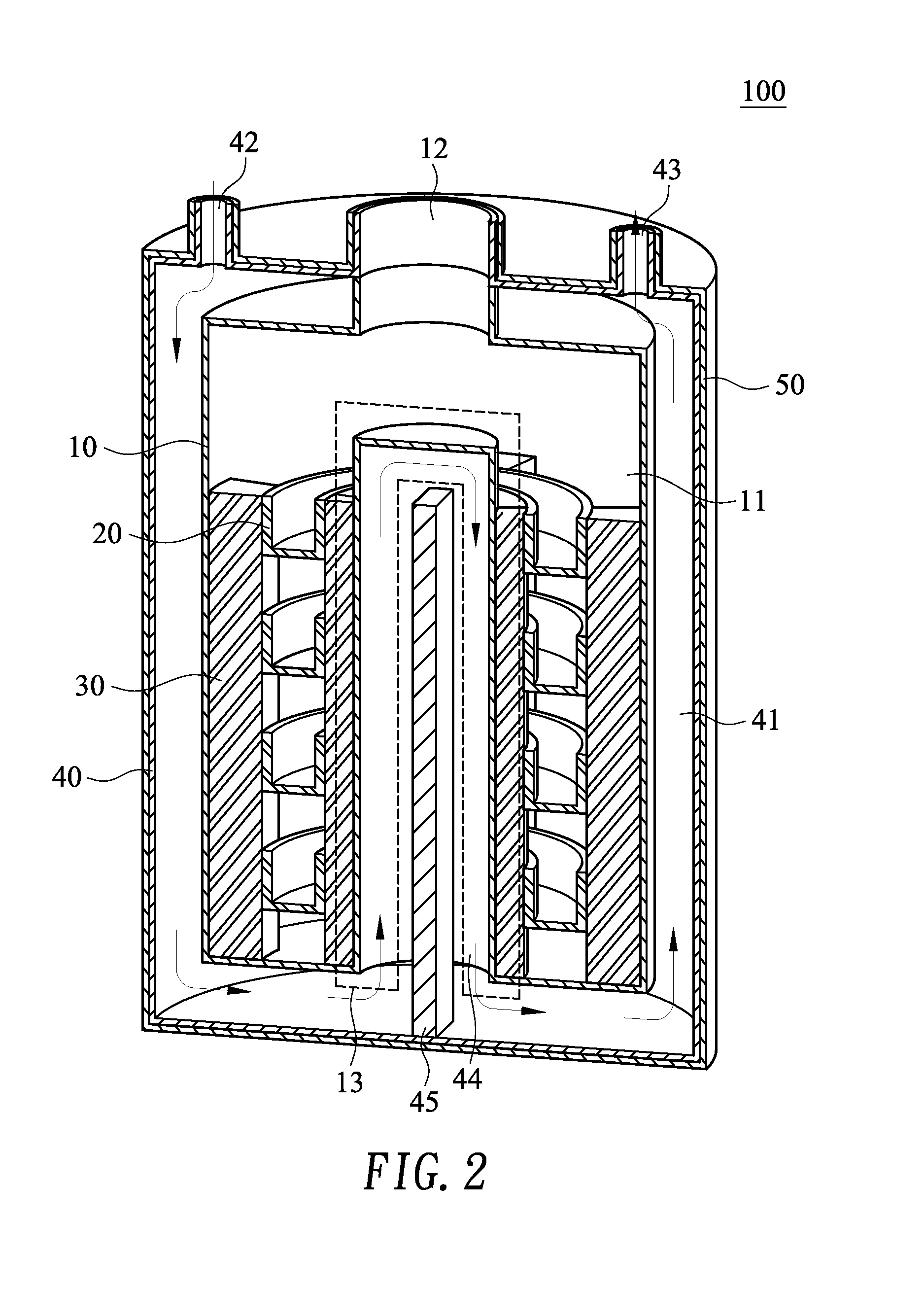

Referring to FIG. 1 through FIG. 3, the present embodiment shows a hydrogen storage device 100 for storing hydrogen gas. The hydrogen storage device 100 includes: a first casing 10, at least one hydrogen container 20, at least one stress buffering unit 30, and a second casing 40.

As shown in FIG. 2, the first casing 10 is formed therein with a first space 11 and thereon with a first opening 12. The first opening 12 allows the first space 11 to intercommunicate with the external environment, and allows hydrogen gas to be introduced into the first space 11 therethrough. The first casing 10 may include at least one depressed portion 13, which is formed by depressing the first casing 10 inward the first space 11. The depressed portion 13 may be shaped as a column.

The hydrogen container 20, which may be a top-opened annular container, is set inside the first space 11 for receiving a hydrogen storage material. Hydrogen gas is introduced into the first space 11 from the external environment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Transmission | aaaaa | aaaaa |

| Heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com