Ultraviolet light exposure chamber for photovoltaic modules

a photovoltaic module and ultraviolet light technology, applied in the field of ultraviolet light exposure chambers for photovoltaic modules, can solve the problem of less than a factor of two reduction in exposure intensity, and achieve the effect of reducing exposure intensity, reducing uv exposure intensity, and accelerating testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]Although described with particular reference to UV testing of photovoltaic modules, those with skill in the arts will recognize that the disclosed embodiments have relevance to a wide variety of areas in addition to those specific examples described below.

[0034]All references, including publications, patent applications, and patents, cited herein are hereby incorporated by reference to the same extent as if each reference were individually and specifically indicated to be incorporated by reference and were set forth in its entirety herein.

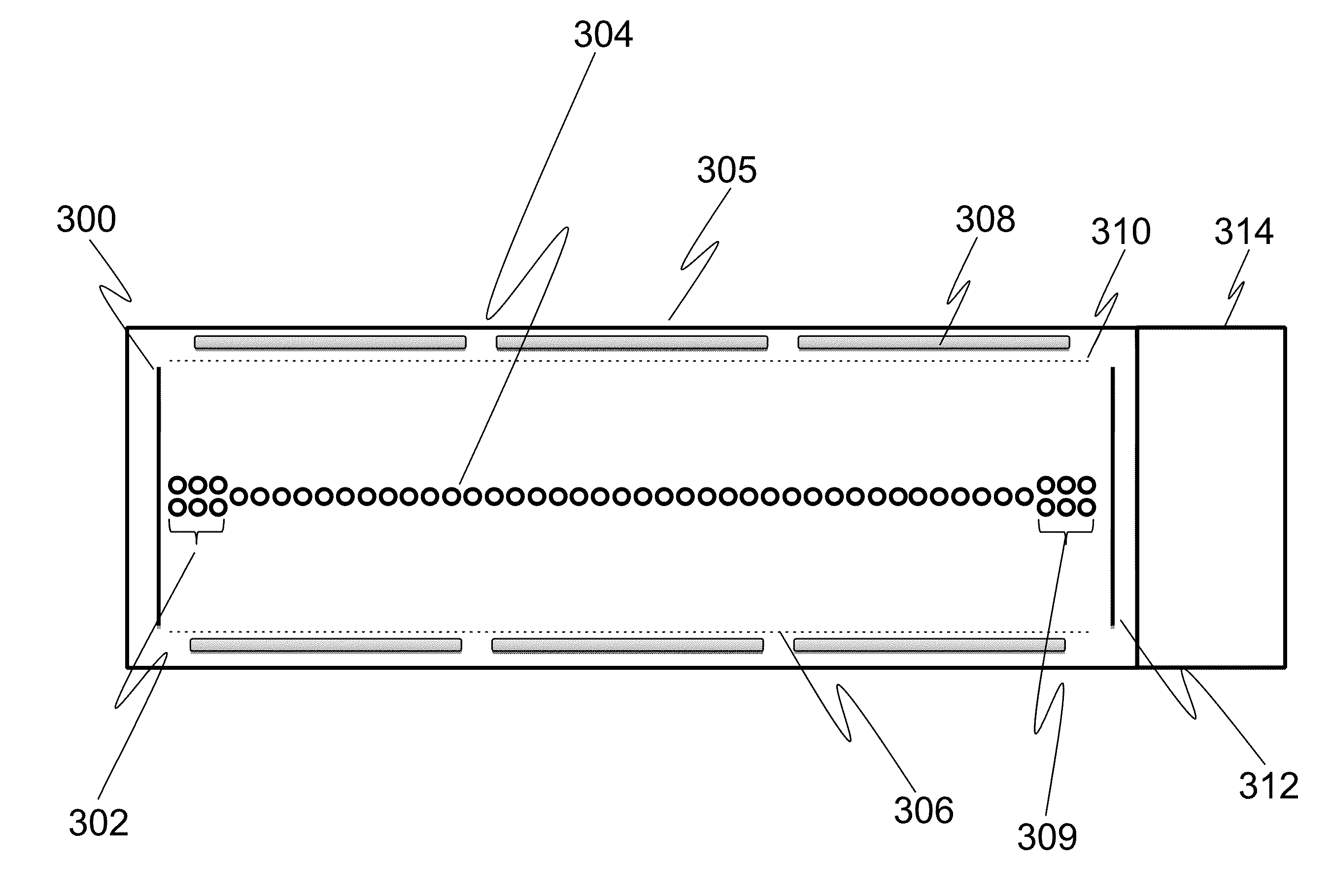

Computing System

[0035]With reference to FIG. 1, an exemplary system within a computing environment for implementing the invention includes a general purpose computing device in the form of a computing system 200, commercially available from Intel, IBM, AMD, Motorola, Cyrix and others. Components of the computing system 202 may include, but are not limited to, a processing unit 204, a system memory 206, and a system bus 236 that couples variou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com