Granulated powder and method for producing granulated powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0133]1) First, as a starting material powder, a 2% Ni—Fe alloy powder (true density: 7.827 g / cm3, manufactured by Epson Atmix Corporation) having an average particle diameter of 6 μm produced by a water atomization method was prepared. Incidentally, the composition of the 2% Ni—Fe is as follows: C: 0.4 to 0.6% by mass, Si: 0.35% by mass or less, Mn: 0.8% by mass or less, P: 0.03% by mass or less, S: 0.045% by mass or less, Ni: 1.5 to 2.5% by mass, Cr: 0.2% by mass or less, and Fe: remainder.

[0134]2) On the other hand, as an organic binder, polyvinyl alcohol (RS-1717, manufactured by Kuraray Co., Ltd.), glycerin (manufactured by Wako Pure Chemical Industries), and an alkylamine derivative (acetate) were prepared. Further, as a solvent, ion exchanged water was prepared. Incidentally, the addition amount of the solvent was set to 50 g per gram of the organic binder. Further, the saponification degree of the polyvinyl alcohol was 93 and the polymerization degree thereof was 1700.

[0135]...

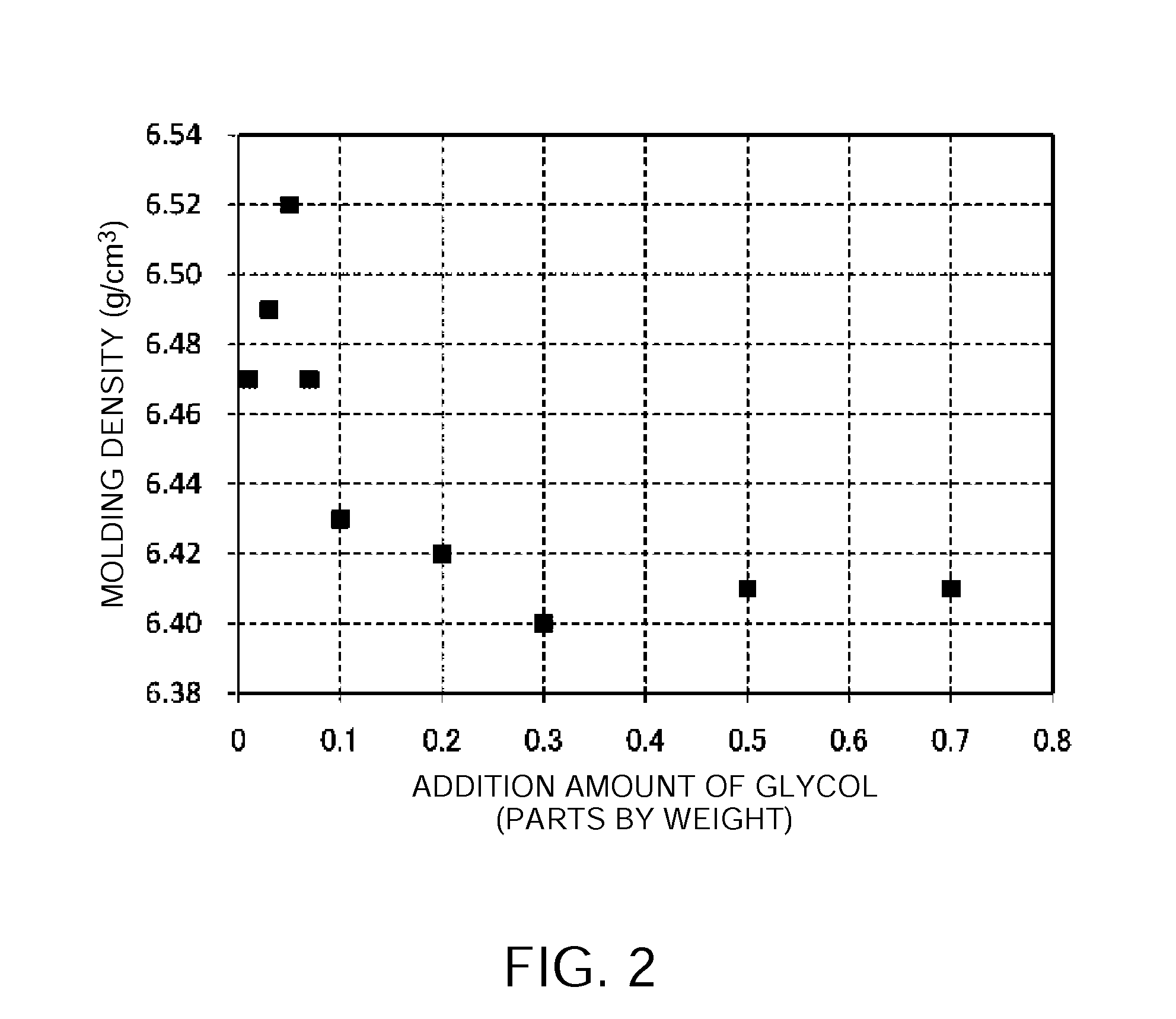

examples 2 to 9

[0142]Granulated powders were obtained in the same manner as in Example 1 except that the addition amount of glycerin was changed as shown in Table 1, respectively.

examples 10 to 15

[0143]Granulated powders were obtained in the same manner as in Example 3 except that the addition amount of the organic amine was changed as shown in Table 1, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com