Knitted geotextile, and geotextile tube constructed thereof

a geotextile and knitted technology, applied in knitting, ornamental textile articles, separation processes, etc., can solve the problems of unfavorable impact, woven fabrics tend to “tighten up”, and certain performance disadvantages of weaving technology, so as to achieve higher performance and lower strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0050]

ENGLISH / TESTIMPERIALSI / METRICPROPERTYMETHODSVALUESVALUESTubeCircumferenceMeasured14′4″ / 28′8″ / 43′4.4 m / 8.8 m / (nominal)13.2 mLength (standard)Measured100′ / 150′ / 300′30 m / 45 m / 90 mFill port sizeMeasured12″ / 18″300 mm / 450 mm(diameter)Fill port spacingMeasured25′ / 50′7.5 m / 15 m(typical)Fabricator seamASTM D4884400 lbf / in70 kN / mstrengthGeocompositeWide width tensileASTM D4595690 / 690 lbf / in120 / 120 kN / mstrengthExtension at breakASTM D459511.8 / 10.1%Puncture strengthASTM D4833600 lb2650NApparent openingASTM D4751230 US0.068 mmsize (AOS)standardsieve equiv.PermittivityASTM D44910.95 / sFlow rateASTM D449178 gal / min / ft23130 l / min / m2EnduranceUV resistance %ASTM D435559% @ 500 hremaining

example 2

[0051]

ENGLISH / TESTIMPERIALSI / METRICPROPERTYMETHODSVALUESVALUESTubeCircumferenceMeasured14′4″ / 28′8″ / 43′4.4 m / 8.8 m / (nominal)13.2 mLength (standard)Measured100′ / 150′ / 300′30 m / 45 m / 90 mFill port sizeMeasured12″ / 18″300 mm / 450 mm(diameter)Fill port spacingMeasured25′ / 50′7.5 m / 15 m(typical)Fabricator seamASTM D4884600 lbf / in105 kN / mstrengthGeocompositeWide width tensileASTM D4595810 / 810 lbf / in140 / 140 kN / mstrengthExtension at breakASTM D459512.7 / 8.0%Puncture strengthASTM D4833600 lb2650NApparent openingASTM D4751230 US0.069 mmsize (AOS)standardsieve equiv.PermittivityASTM D44911.12 / sFlow rateASTM D449192 gal / min / ft23690 l / min / m2EnduranceUV resistance %ASTM D435559% @ 500 hremaining

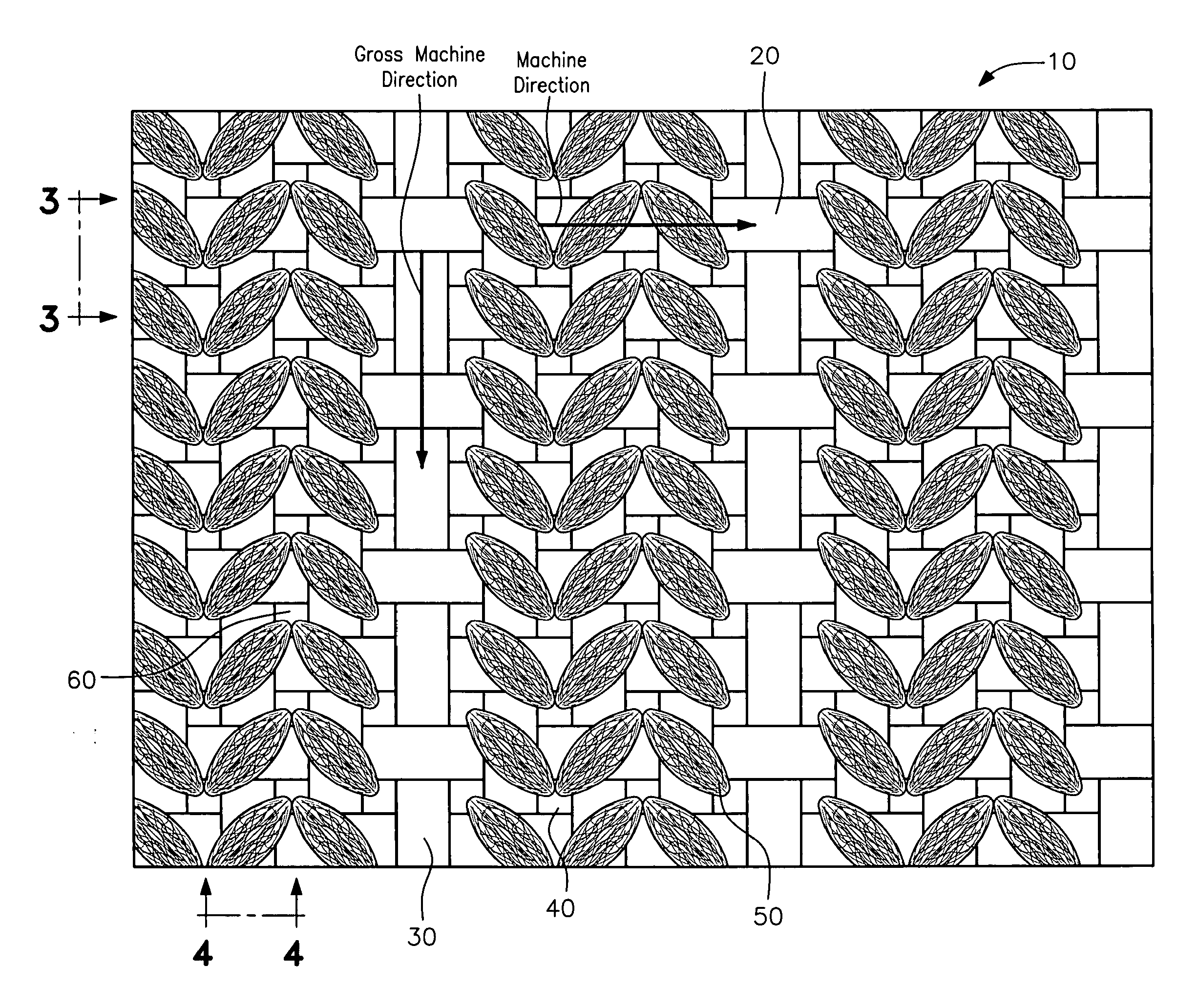

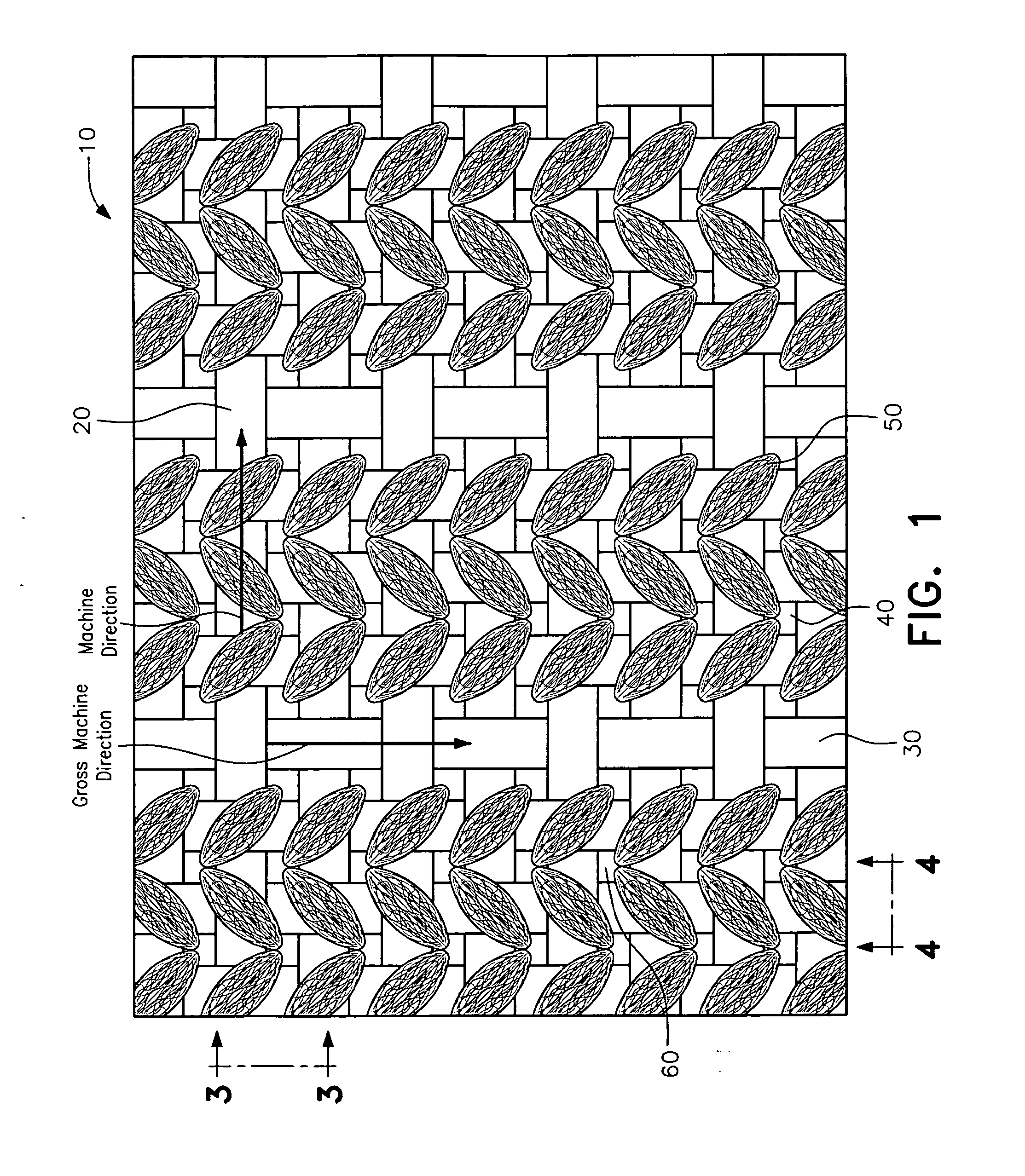

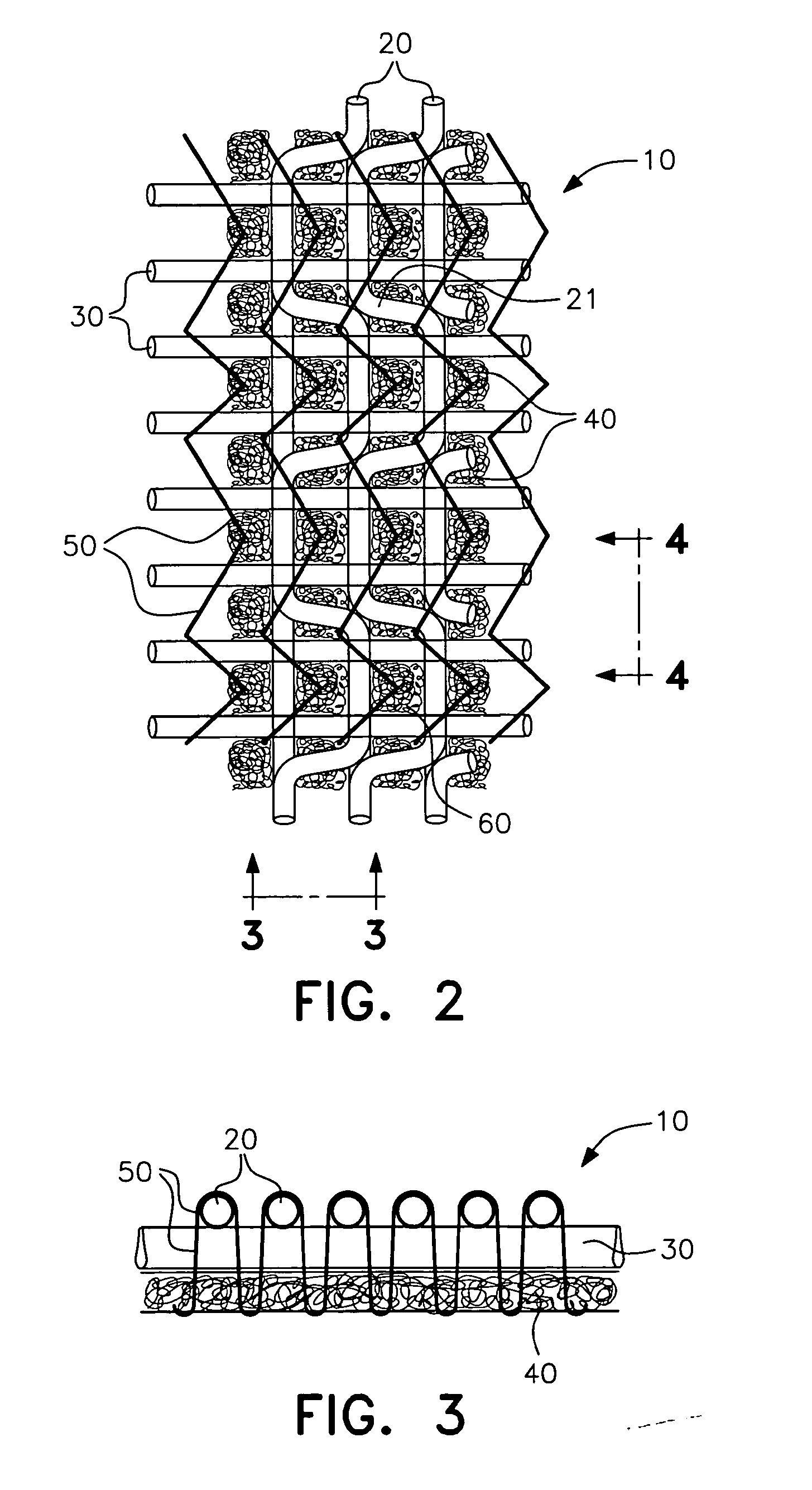

[0052]FIG. 9 is an enlarged plan view of a knitted geotextile 210 in accordance with another embodiment of the present invention in which the fabric includes multi-axial weft insertion. The knitted geotextile 210 includes a pattern of oriented warp fibers 20 positioned substantially parallel to each other, a patt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com