X-ray waveguide

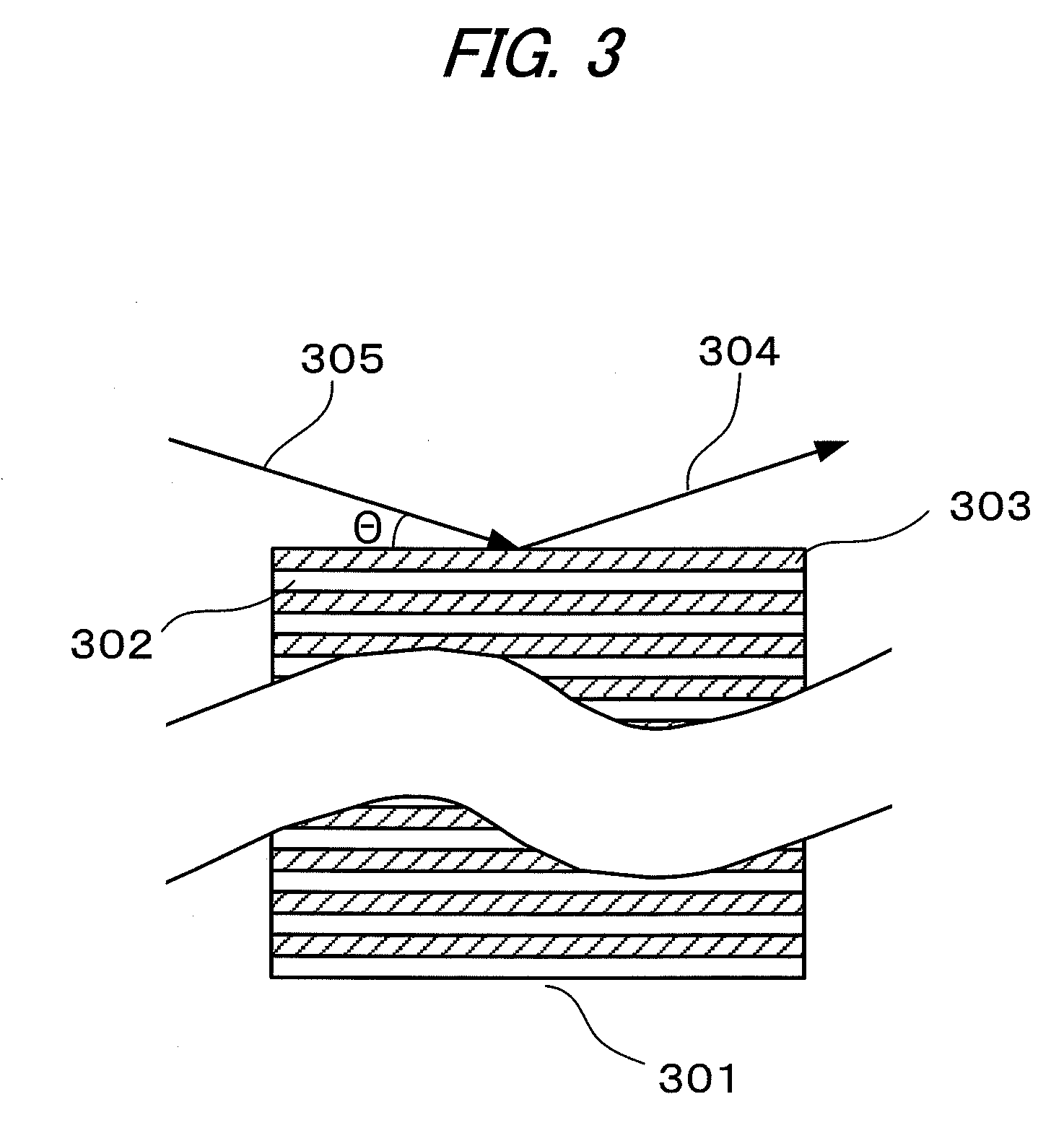

a waveguide and x-ray technology, applied in the field of x-ray waveguides, can solve the problems of increasing the propagation loss of x-ray, difficult to produce a core region, deterioration or structural change of the waveguide, etc., and achieves the effect of small propagation loss of an x-ray and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

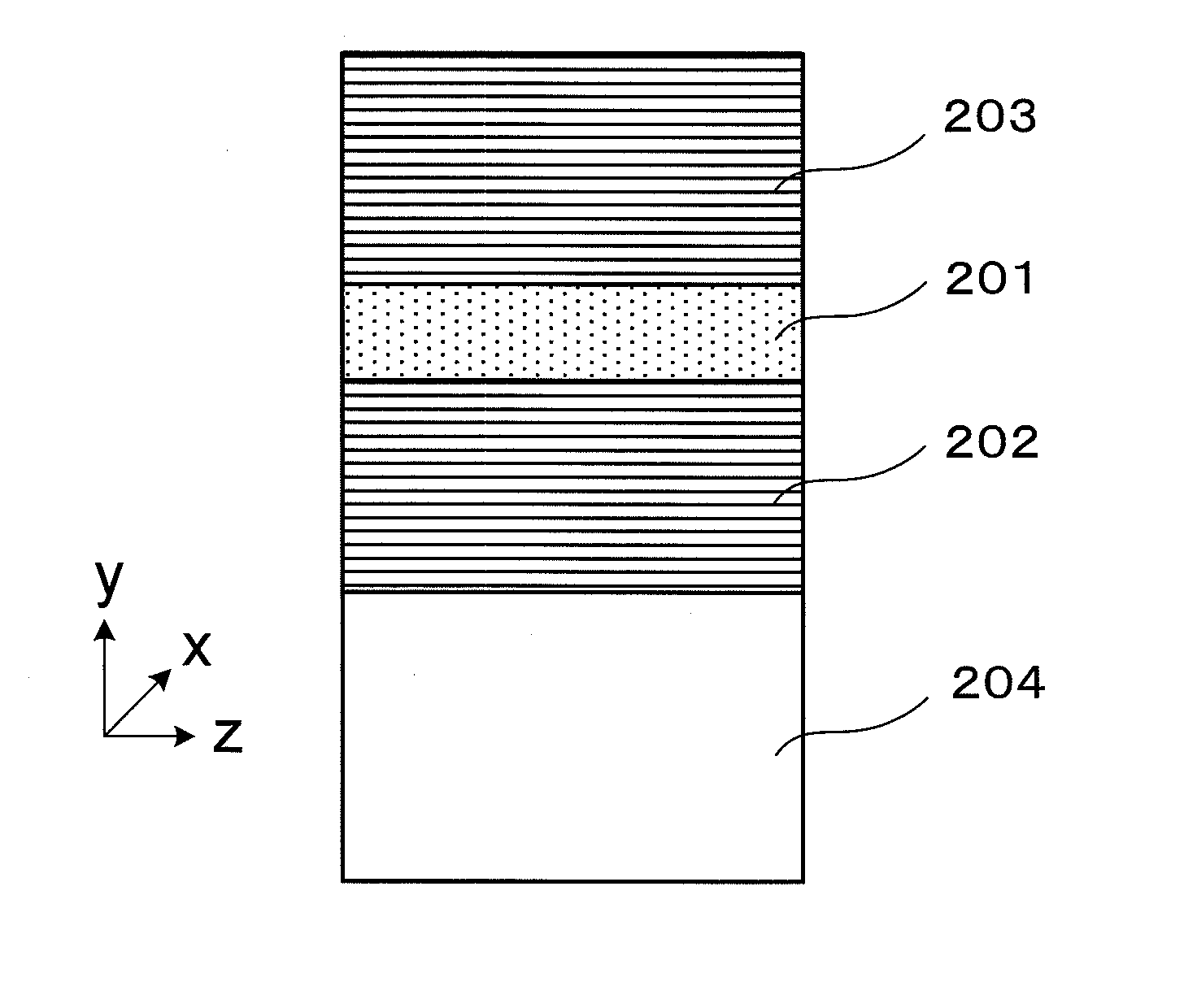

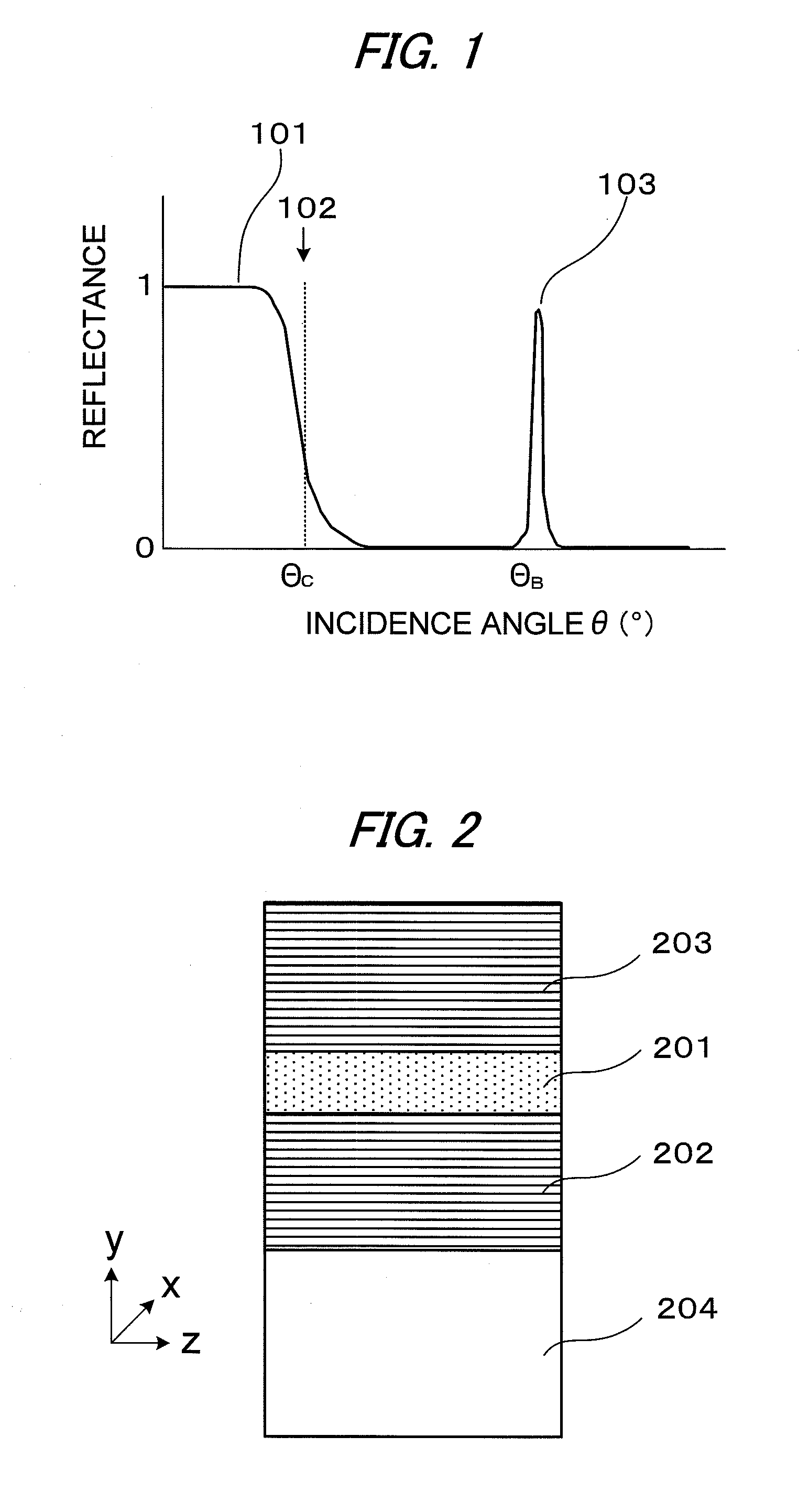

[0061]FIG. 2 is a view illustrating Example 1 of the X-ray waveguide of the present invention. A lamellar film 202 formed as a multilayer film to serve as a cladding is formed on an Si substrate 204. Then, PDMS having a thickness of about 32 nm is formed as a core 201 on the film by spin coating. Further, a lamellar film 203 is formed on the core. The inorganic material of the lamellar films is SiO2. The lamellar films 202 and 203 of this example are produced by the following method.

[0062](a) Preparation of Solution

[0063]A mesostructured film having a lamellar structure is prepared by a spin coating method. A precursor solution is prepared by dissolving n-decyltrimethoxysilane, tetramethoxysilane, water, and hydrochloric acid in a tetrahydrofuran solvent, and stirring the resultant at 25° C. for 3 hours. The mixing ratio (molar ratio) of n-decyltrimethoxysilane, tetramethoxysilane, water, hydrochloric acid, and tetrahydrofuran is set to 1:4:19:0.01:20.

[0064](b) Film Formation

[0065]A...

example 2

[0071]FIG. 4 is a view illustrating Example 2 of the X-ray waveguide of the present invention. The claddings of this example are the films of a mesoporous silica (mesoporous material) whose inorganic material is silica (SiO2), and the inside of each pore of the film is filled with air. The X-ray of waveguide mode propagates in a z direction in the figure. The X-ray waveguide of this example is such that the film of the mesoporous silica is formed as a cladding 402 or 403. However, a core 401 is formed of air. The mesoporous silica film is of a structure having a one-dimensional periodicity in a y direction in the figure, and the period of the structure is about 6 nm. A lamellar film is formed on each of Si substrates 404 and 405, and Au pattern of about 50 nm height is made on the surface of each Si substrates by sputtering, lithography, and etching process. After that, both the Si substrates are attached to each other so that the respective mesoporous silica films may be opposite t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com