Specimen freezing rate regulator device

a regulator device and freezing rate technology, applied in the field of specimen freezing rate regulator devices, can solve the problems of reducing the survival of cells upon thawing, affecting the efficiency of cell survival,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experiment 1

y of Specimen Freezing Cycle

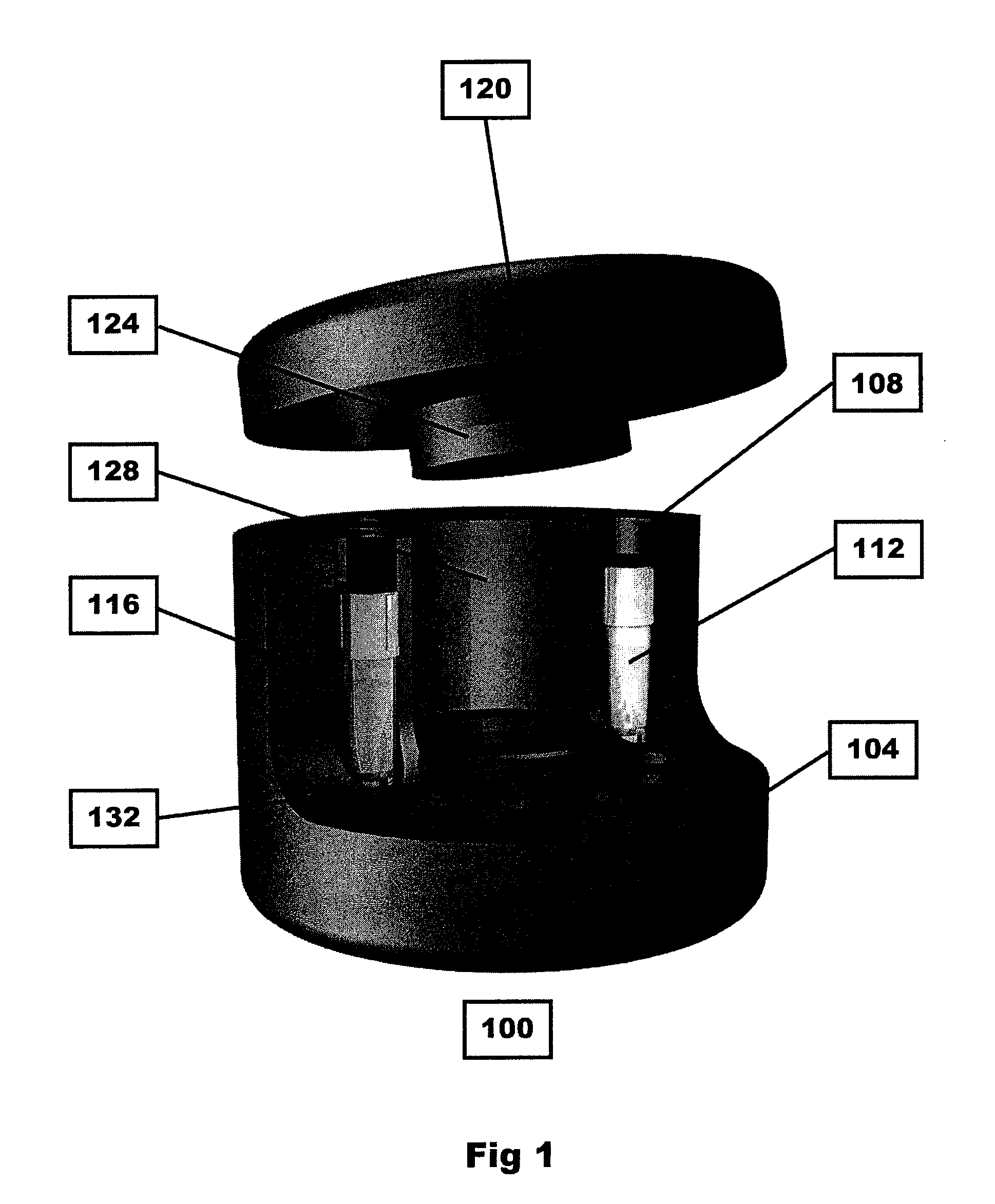

[0030]With reference to FIG. 3, the results from an experiment are shown. This experiment was conducted using a prototype device 100 as shown in FIG. 1. The device 100 was loaded with 12 specimen vials containing 1 ml of cryoprotectant solution each. The device 100 was then closed by replacing the cover, and the device and cover were placed in a −80° C. freezer compartment. The cryoprotectant load of one vial was monitored using a thermocouple probe introduced through the cover of the device and through the screw-cap lid of the specimen vial. The temperature of the cryoprotectant solution was recorded using an electronic data recorder that collected sample data at 10 second intervals. Following a four hour interval, the assembly was removed from the freezer disassembled and the device and sample vials re-equilibrated to 20° C. The sample vials were re-loaded and the freezing cycle described was repeated a total of 5 times. The combined graphic plots of th...

experiment 2

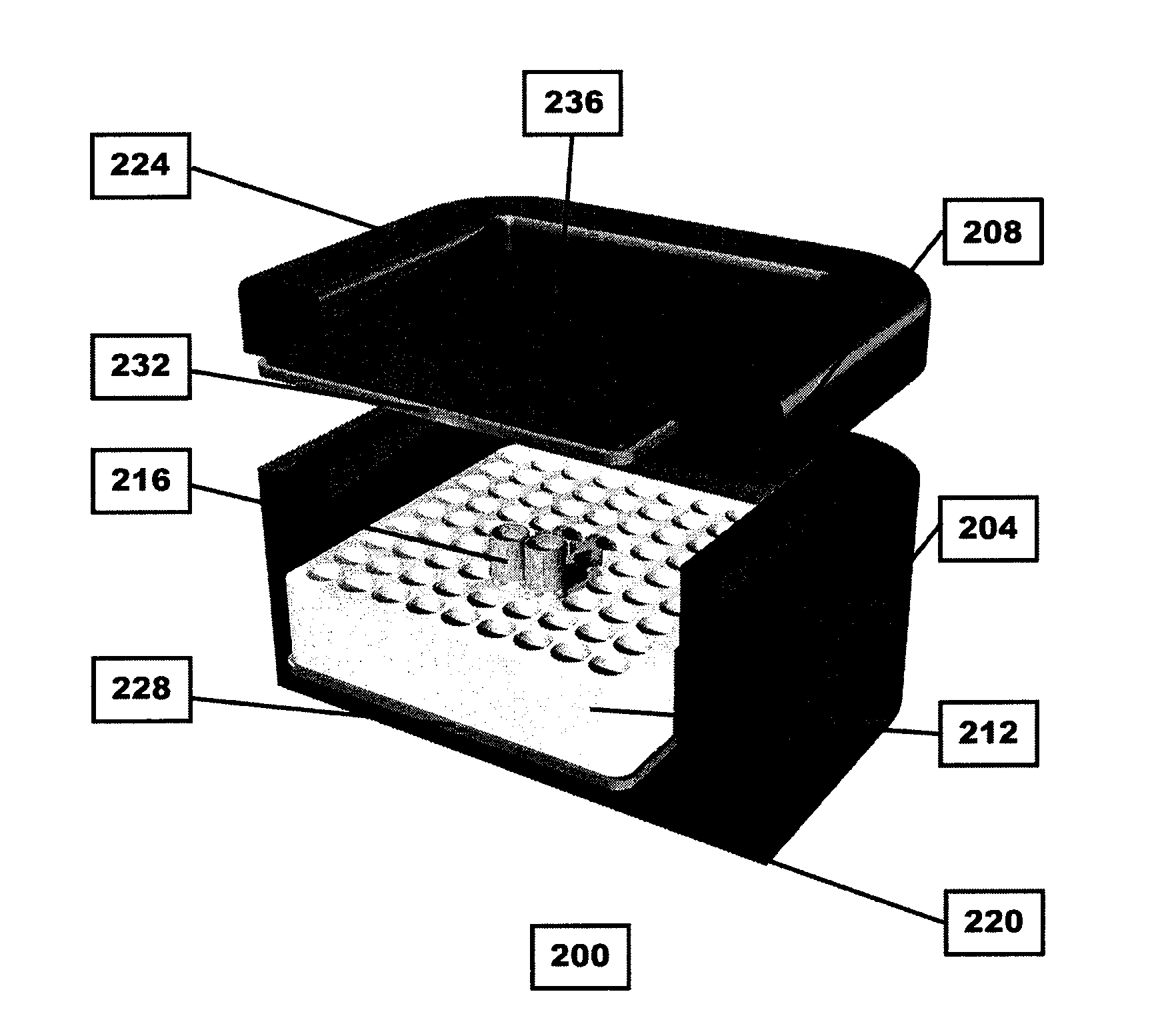

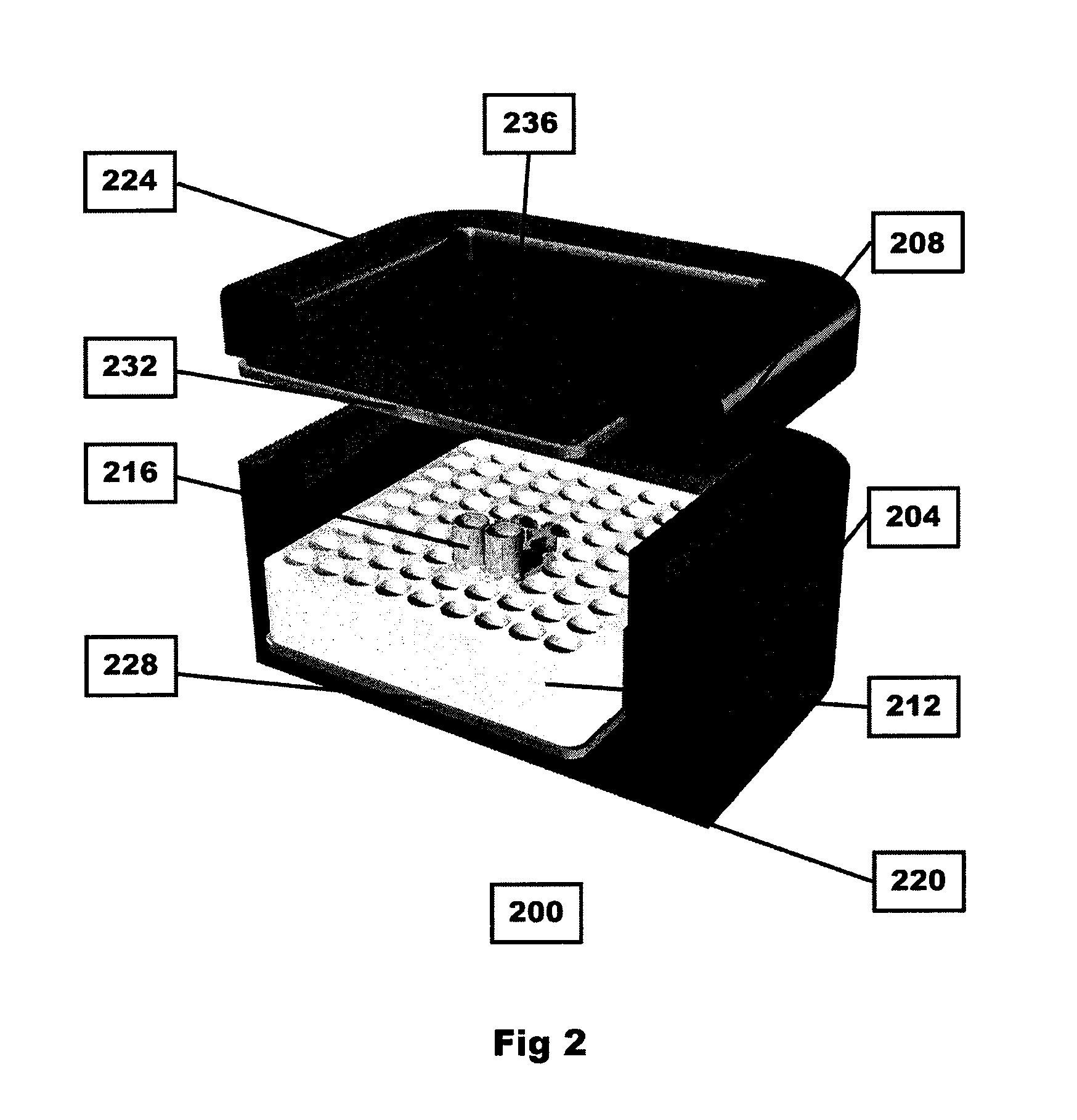

ezing Rate Regulator with Central Ballast Mass

[0031]With reference to FIG. 4, the results from an experiment are shown. This experiment was conducted using a prototype device 100 with and without a ballast 132, as shown in FIG. 1. The device 100 was loaded with 12 specimen vials containing 1 ml of cryoprotectant solution each, then closed by replacing the cover after which the assembly was placed in a −80° C. freezer compartment. The cryoprotectant load of one vial was monitored using a thermocouple probe introduced through the cover of the device and through the screw-cap lid of the specimen vial. The temperature of the cryoprotect solution was recorded using an electronic data recorder that collected sample data at 10 second intervals. Following a four hour interval, the assembly was removed from the freezer disassembled and the device and sample vials re-equilbrated to 20° C.

[0032]Four separate freezing cycles are shown in which the central cavity of the device contained no addit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volumes | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thermal | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com