Low-carbon resulfurized free-machining steel excellent in machinability

a free-machining steel and low-carbon resulfurized technology, applied in the field of low-carbon resulfurized free-machining steels, can solve the problems of harm to the human body, lead-containing free-machining steels have some problems, and cannot achieve machinability in view of finished surface roughness upon forming as good as with lead-containing steels, and achieve good finished surface roughness and good productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

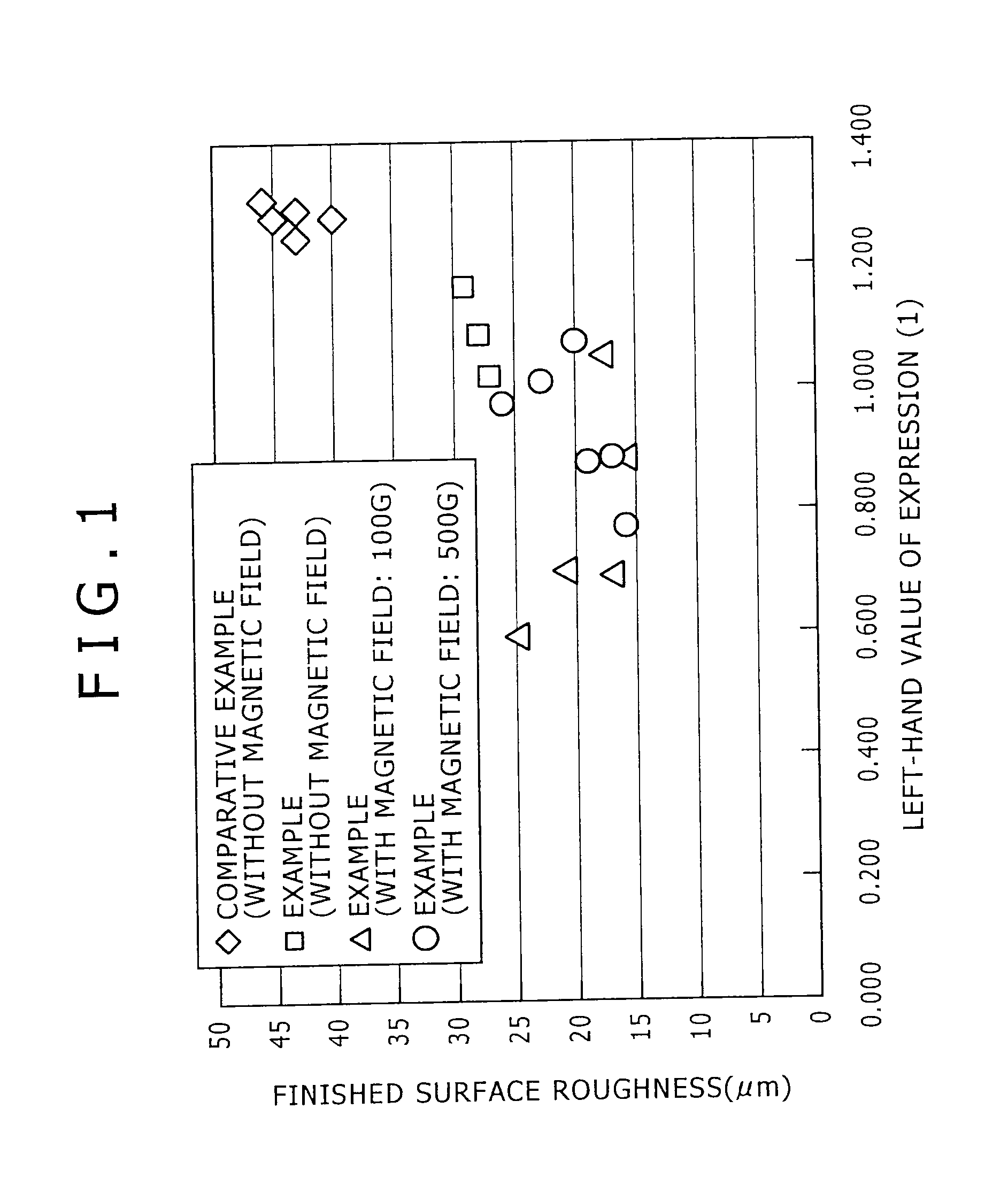

[0088]A series of molten steels having varying contents of, for example, Si, Mn, S, Al, and N were made using a 3-ton induction furnace, a 100-ton converter, and molten steel refining facilities including a pouring ladle. In this procedure, the silicon and aluminum contents were adjusted by varying the silicon and aluminum contents in Fe—Mn alloys and Fe—S alloys to be added, respectively. The free oxygen contents in the resulting molten steels were determined immediately before casting into a predetermined mold using a free oxygen probe (the product of Heraeus Electro-Nite under the trade name of “HYOP 10A-C150”), and they were defined as the free oxygen contents.

[0089]The molten steels were subjected to continuous casting using a (bloom-type) mold having a sectional size of 300 mm wide and 430 mm long. Alternatively, they were cast in the 3-ton induction furnace using a cast-iron mold having a sectional size of 300 mm wide and 430 mm long which had been designed to achieve a cooli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| magnetic field | aaaaa | aaaaa |

| defect detector | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com