Heat exchanger of the plate type

a technology of heat exchanger and plate, which is applied in the direction of solar heat collectors with working fluids, stationary conduit assemblies, solar heat devices, etc., can solve the problems of easy detachment of welding, plate delamination, and flat surface, and achieve the effect of increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

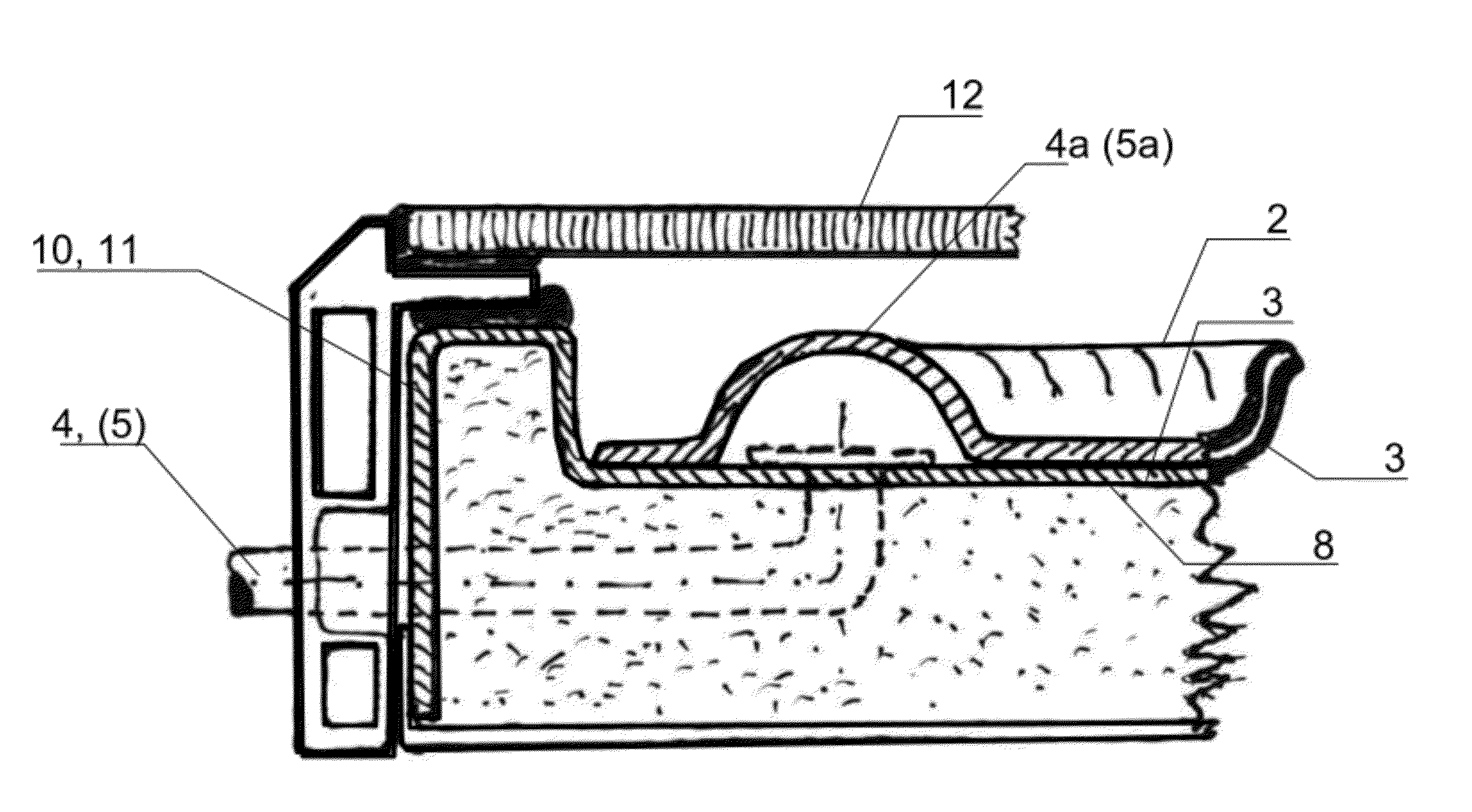

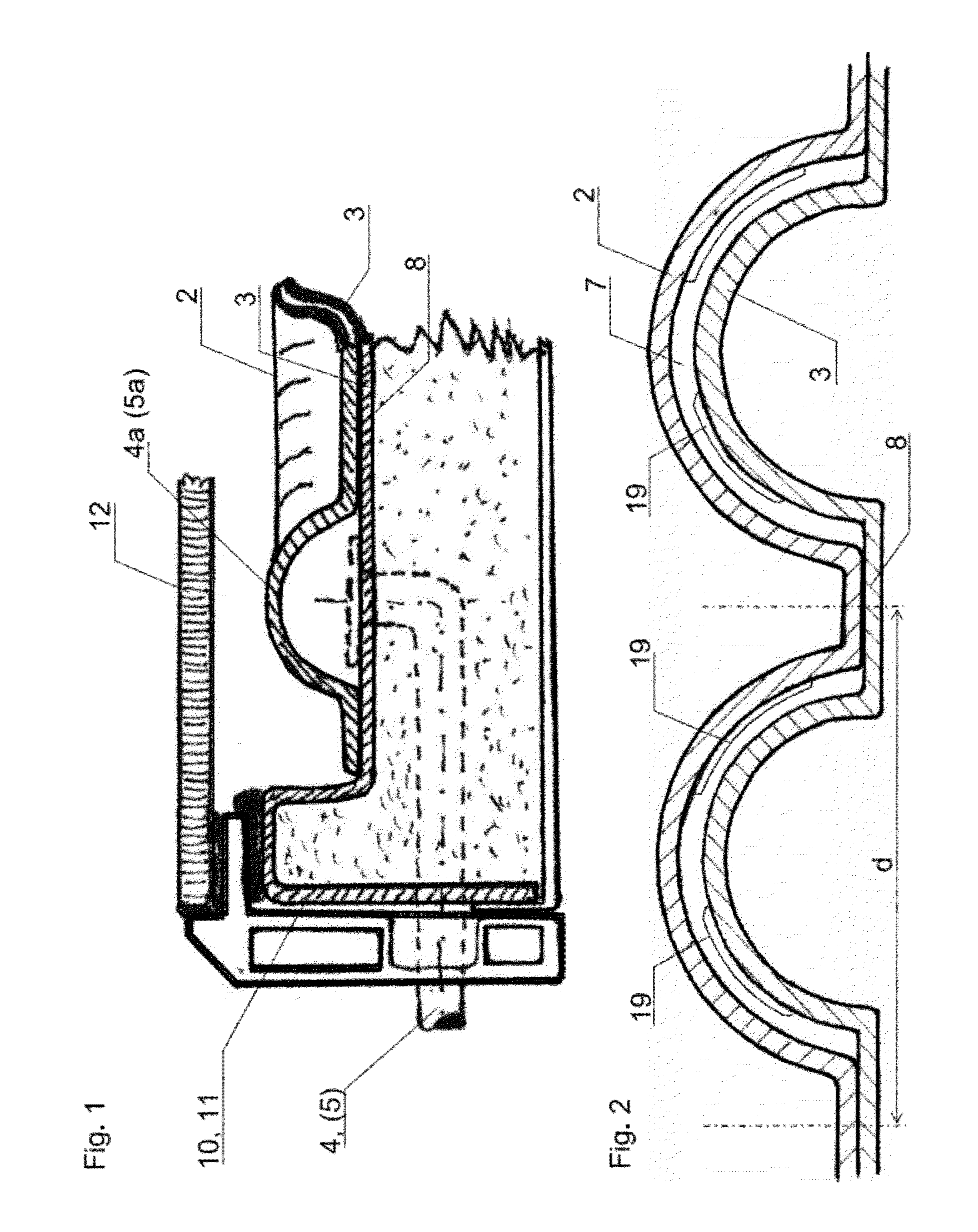

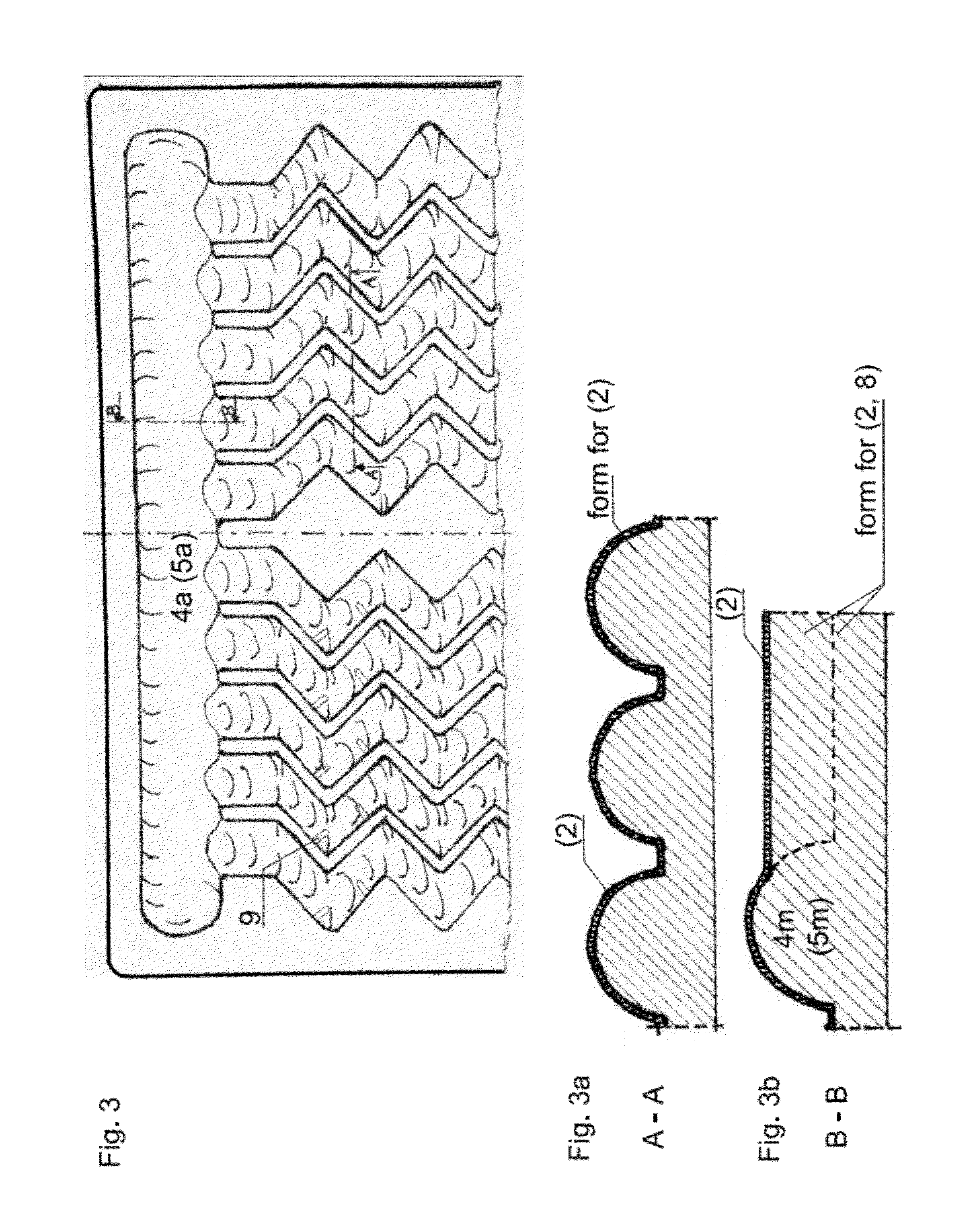

[0027]The invention is a heat exchanger of the plate type, please see FIG. 1, provided with an internal fluid passage for water or other liquid, comprising a first and a second plate (2, 3) whereof at least the first of the plates (2) is arranged to be exposed to a warmer or colder medium. The fluid may be water or another liquid such as antifreeze solution with a high heat capacity. An antifreeze solution will be advantageous in case of outdoor use in a climate with a risk of temperatures below zero degrees Celsius. The internal passage (6) between the two plates (2, 3) is constrained by manifolds (4a, 5a) to an inlet (4) and an outlet (5) for the fluid. The passage (6) forms a widening between the inlet (4) and outlet (5) in that it branches into several channels (7). The internal passage (6) is constrained between those two generally parallel plates (2, 3) and wherein the first and the second plate (2, 3) are formed in a structurally self-supporting polymer material.

[0028]In an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com