Method for treatment of iron-based metal surface exposed to superheated steam

a technology of superheated steam and iron-based metals, applied in the direction of corrosion diminishing boiler components, etc., can solve the problems of irregular stop of power plants, affecting the reliability or maintenance of plants, reducing the generation efficiency or increasing maintenance and repair costs, etc., to reduce the frequency of irregular stop, improve reliability and operation efficiency, and reduce maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0037]The invention will be specifically described with reference to the following examples, which are not intended to limit the scope of the invention in any way.

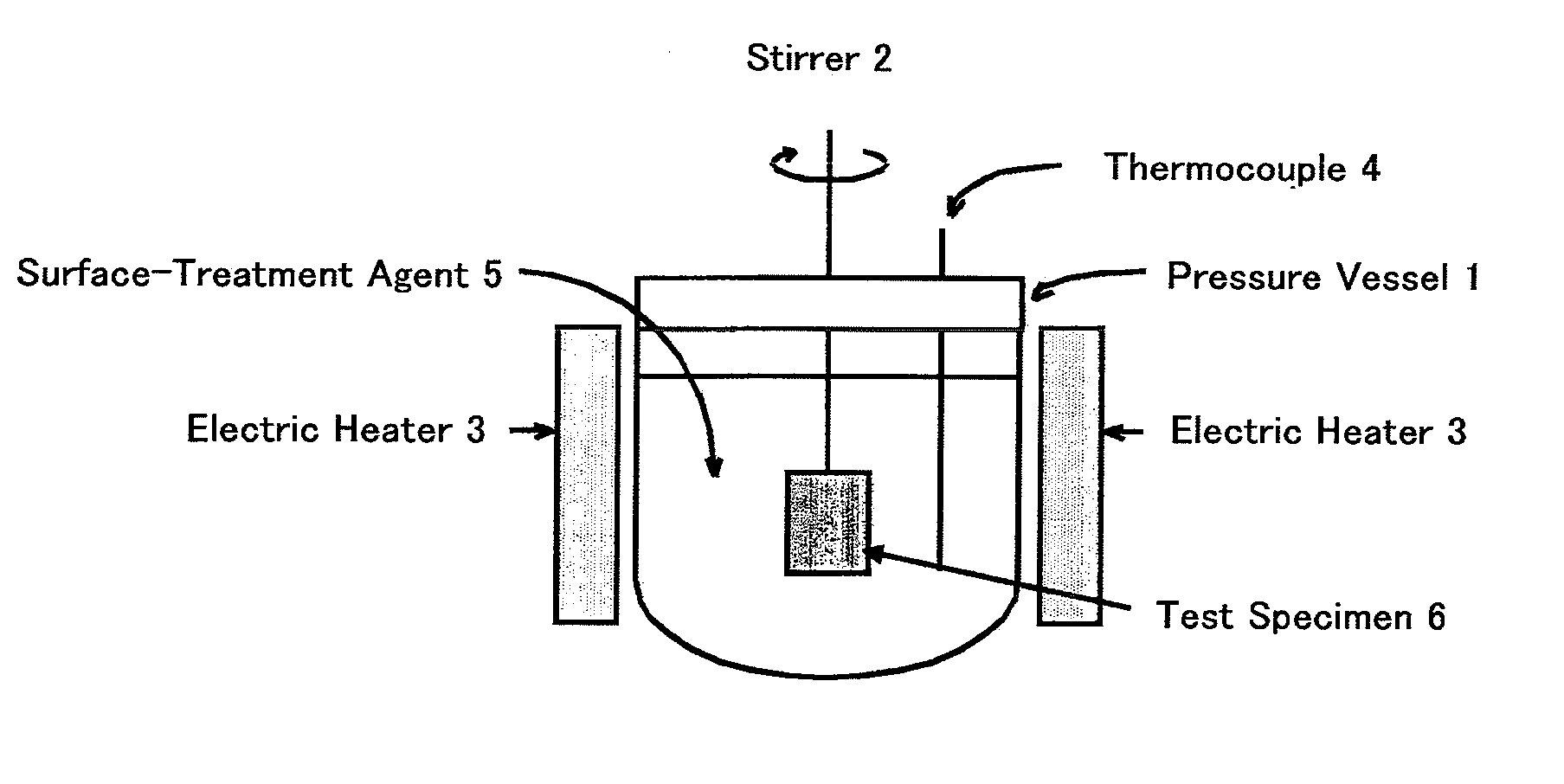

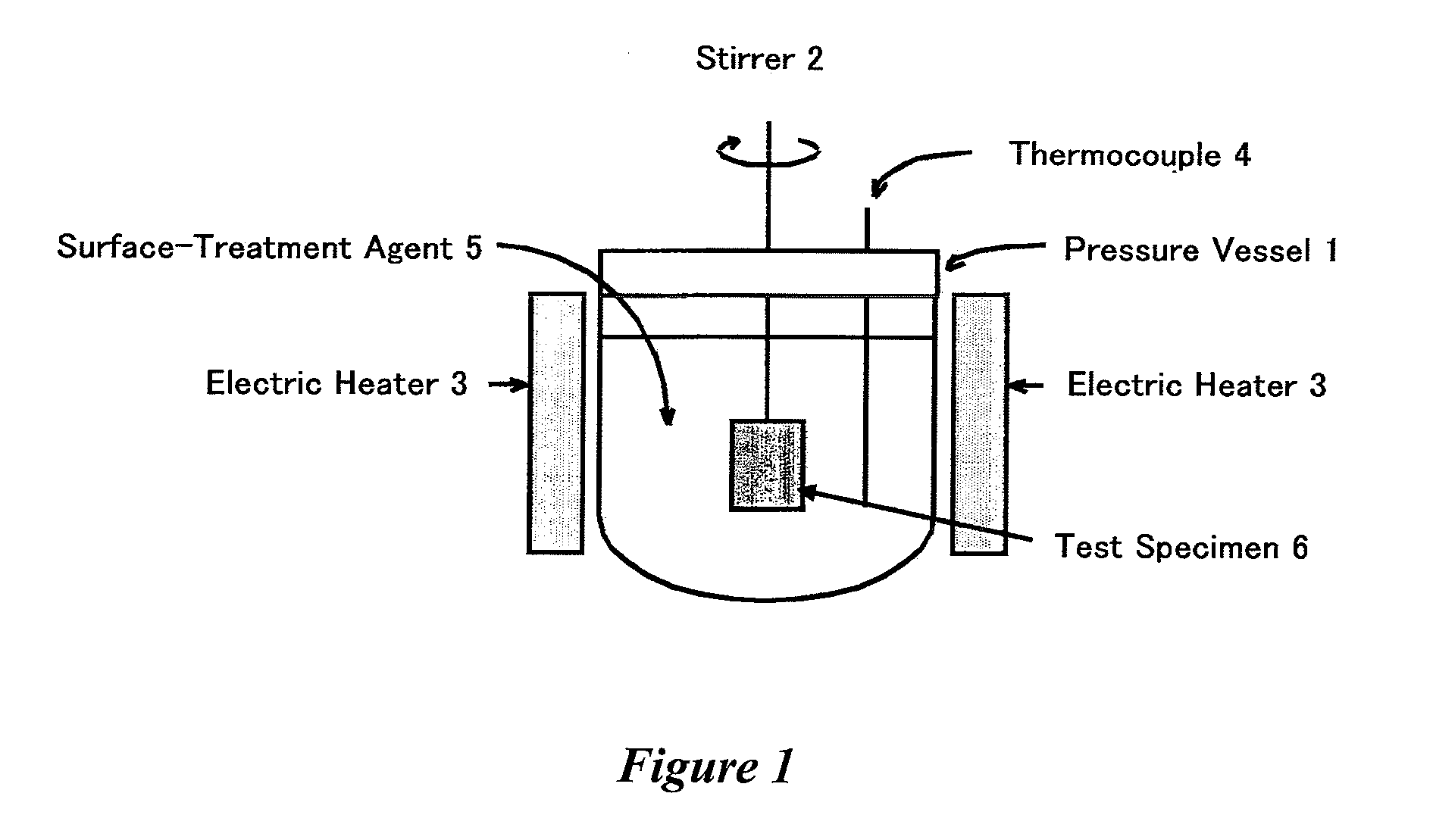

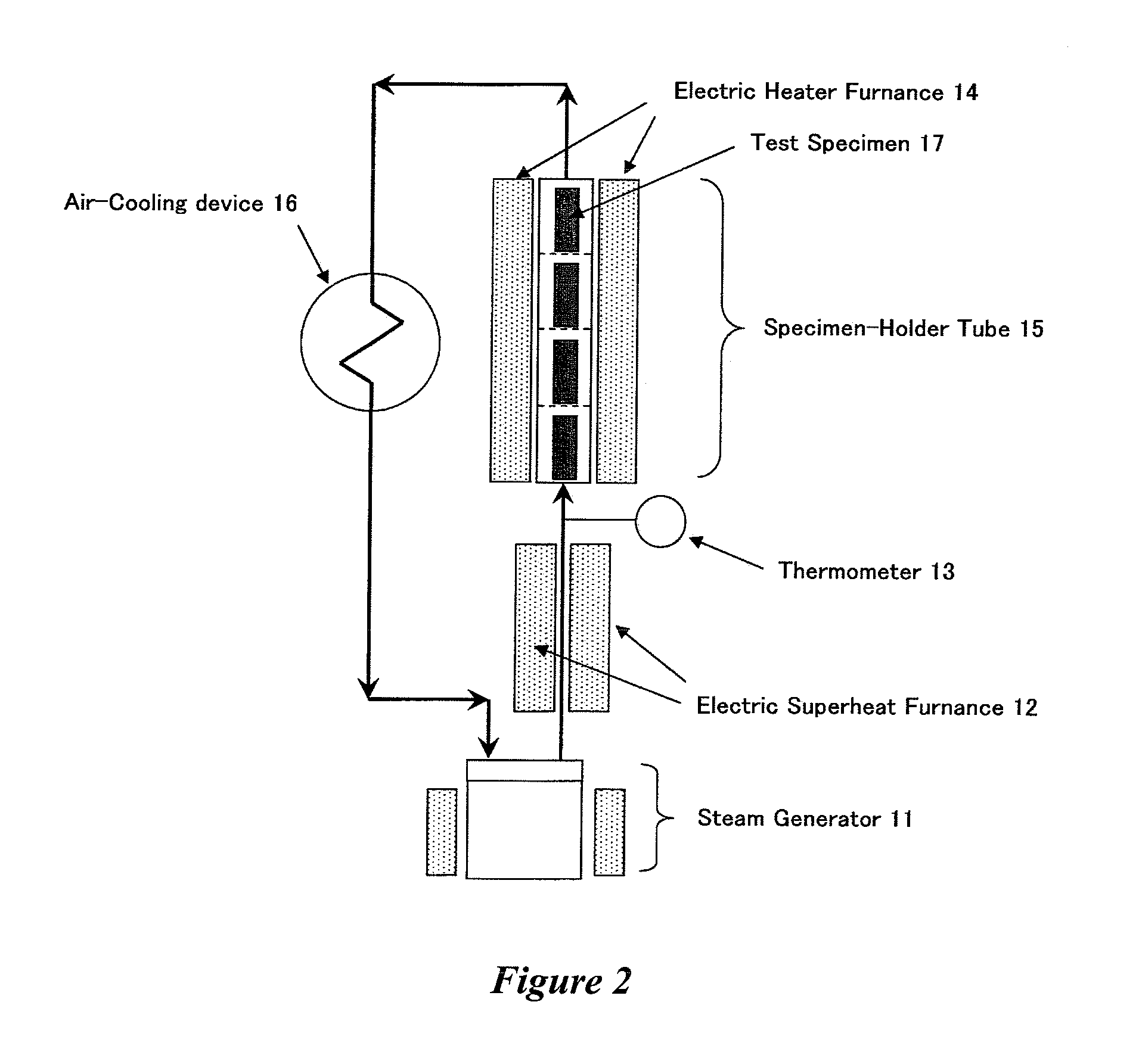

[0038]In the following working and comparative examples, a pipe alloy steel STPA24 (chromium-molybdenum steel) was cut into pieces of 7×100×1 mm, which were used as (iron-based metal) test specimens after polishing with a coated abrasives up to number 400 and defatting with acetone.

[0039]The surface-treatment agents and the treatment conditions used in the examples are given in Tables 1 and 2, respectively.

TABLE 1Surface-treatment agentsComponents and concentrationsAIn a demineralized waterGluconic acid270 mg / LMonoethanolamine450 mg / LMorpholine300 mg / LBIn a demineralized waterTartaric acid300 mg / LMonoethanolamine1500 mg / L CIn a demineralized waterSodium tartrate dihydrate600 mg / LTetraethylenepentamine 30 mg / LSodium hydroxide200 mg / L

TABLE 2Treatment conditionsConditionSurface-treatmentTreatmentTreatment timeNo.agenttemperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com