Method and apparatus for monitoring fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

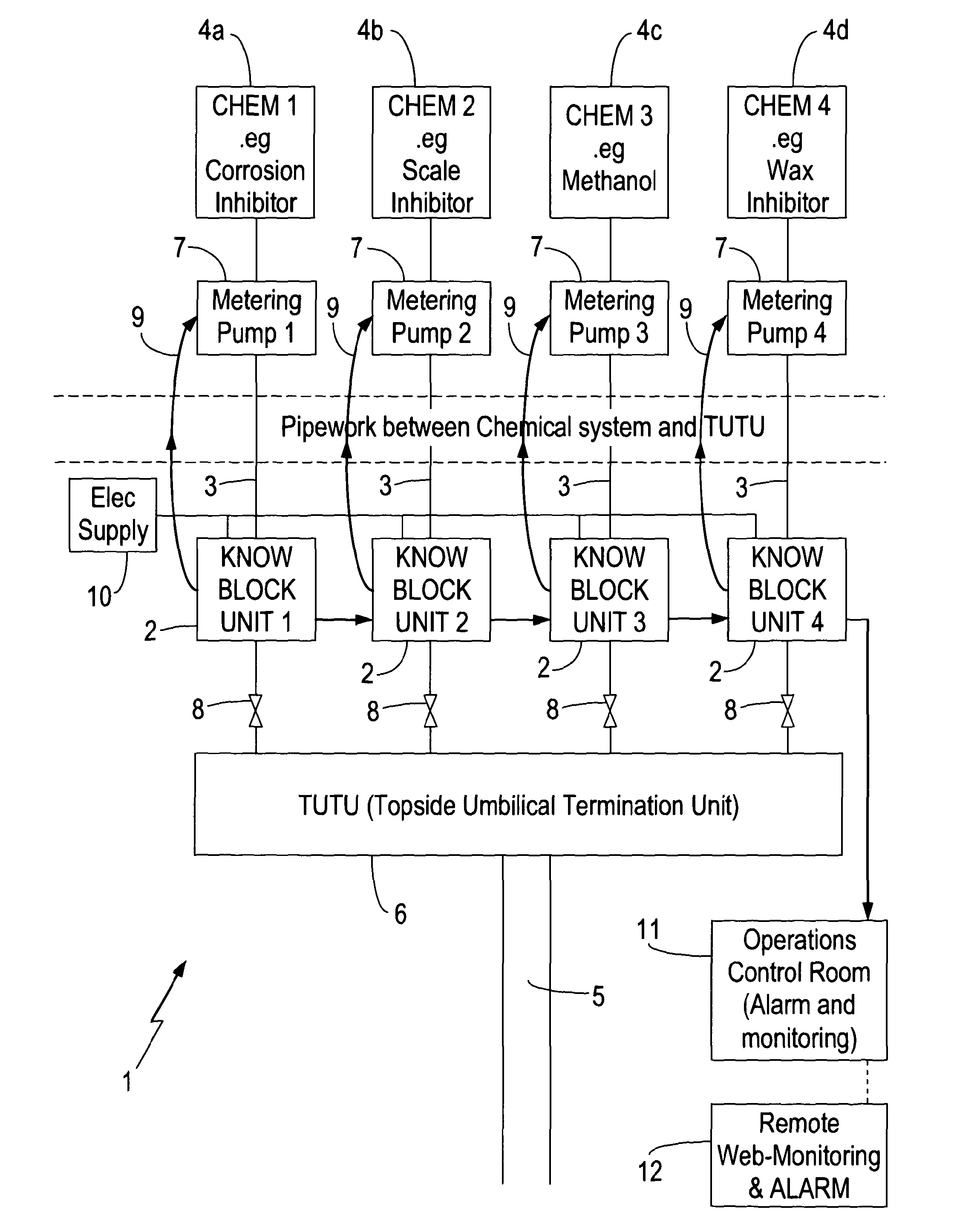

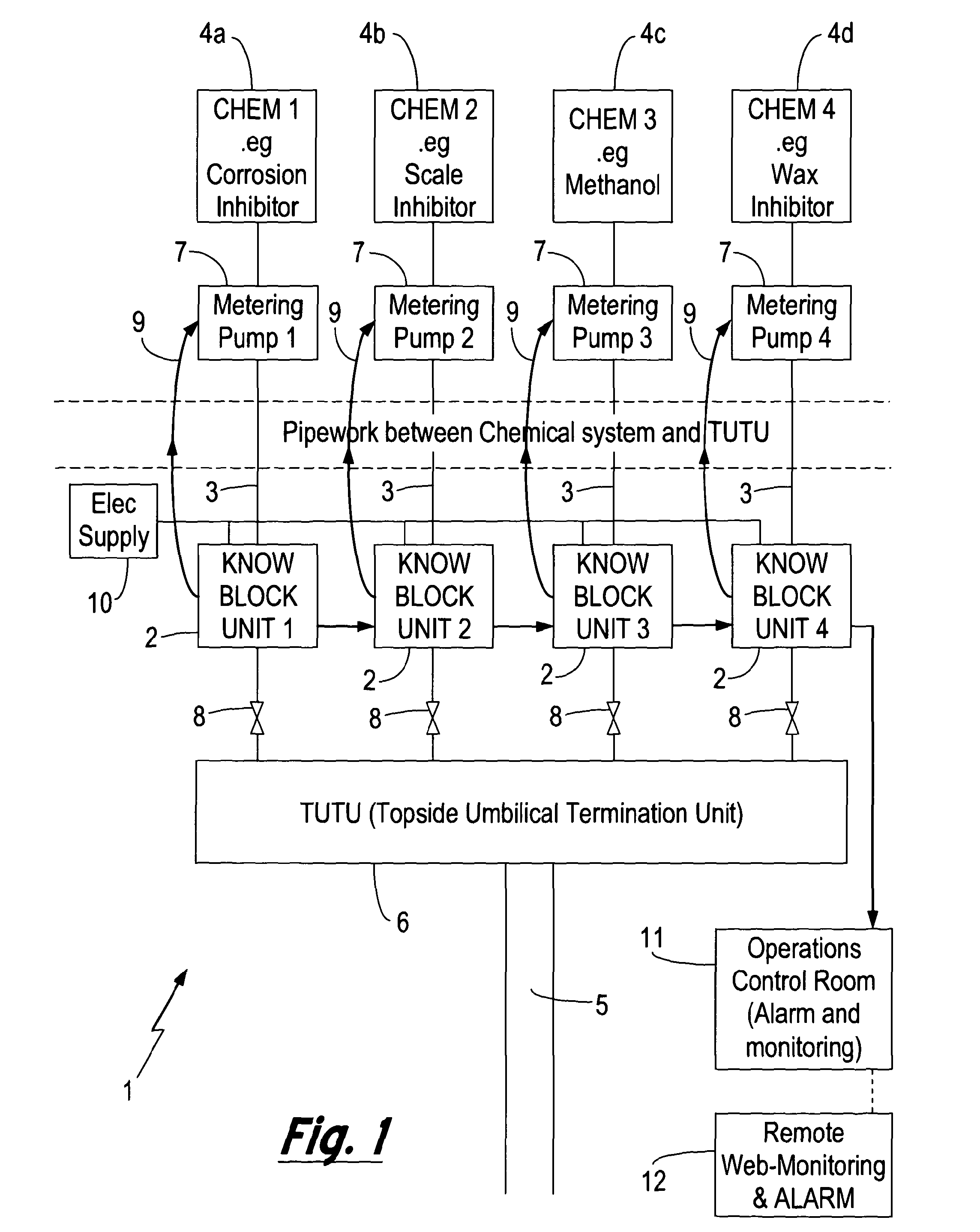

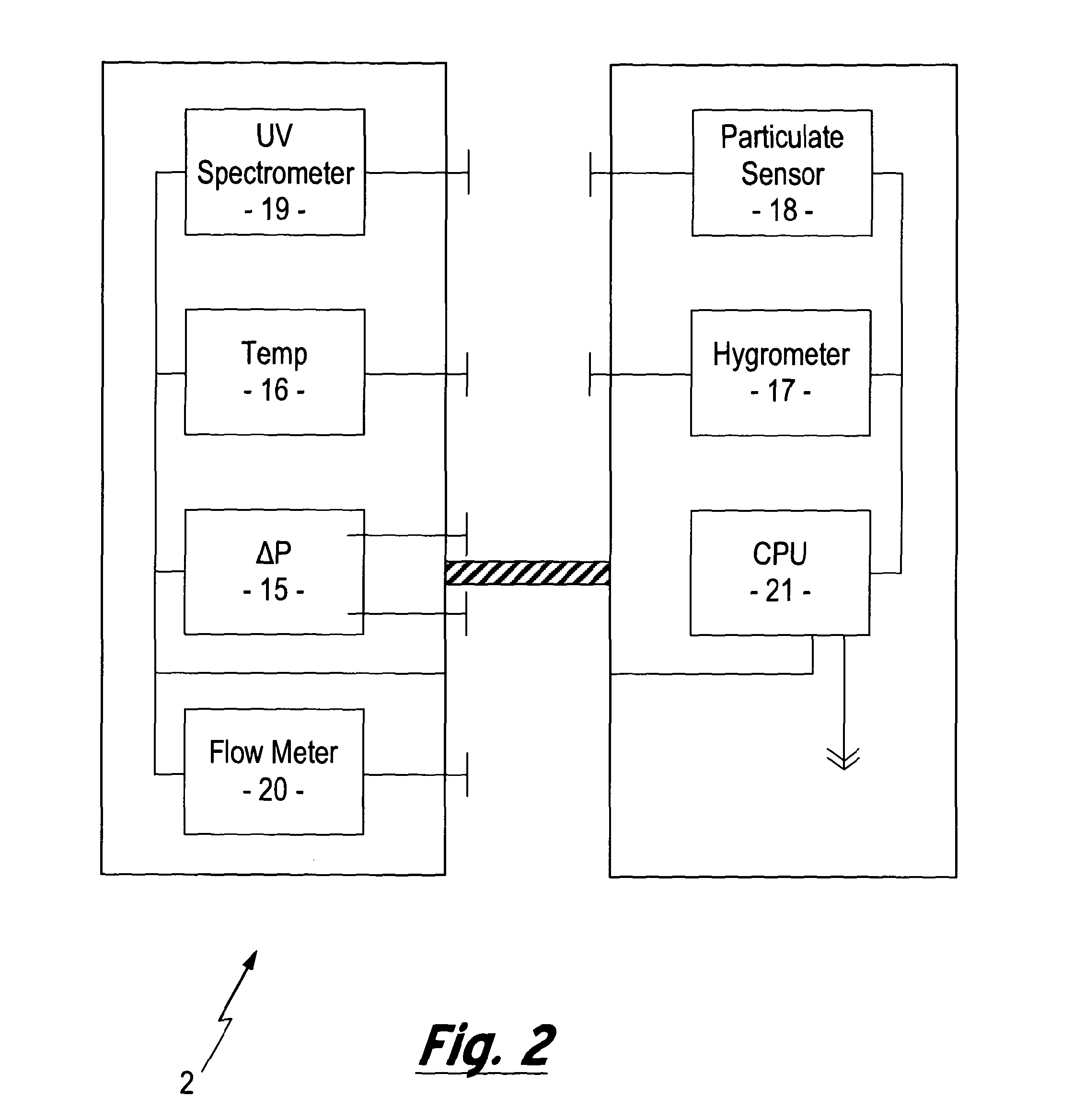

[0071]In order to provide understanding of the various aspects of the present invention a schematic diagram of a surface production facility, generally depicted by the reference numeral 1, is presented in FIG. 1, while FIG. 2 presents a schematic diagram of a fluid monitoring unit 2 employed with the surface production facility 1.

[0072]The surface production facility 1 can be seen to comprise four supply conduits 3 that provide a means for fluid communication between a corresponding fluid source 4 and an umbilical 5 via a topside umbilical termination unit (TUTU) 6. In the presently described embodiment the fluid sources comprise a corrosion inhibitor 4a (one such suitable corrosion inhibitor being that sold by Champion Technologies under the trade mark Scortron® G10000), a scale inhibitor 4b (one such suitable scale inhibitor being that sold by Champion Technologies under the trade mark Gyptron® SA110N), methanol 4c and a wax inhibitor 4d (one such suitable wax inhibitor being that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com