Method and system for extracting a substance by means of Anti-sublimation and melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

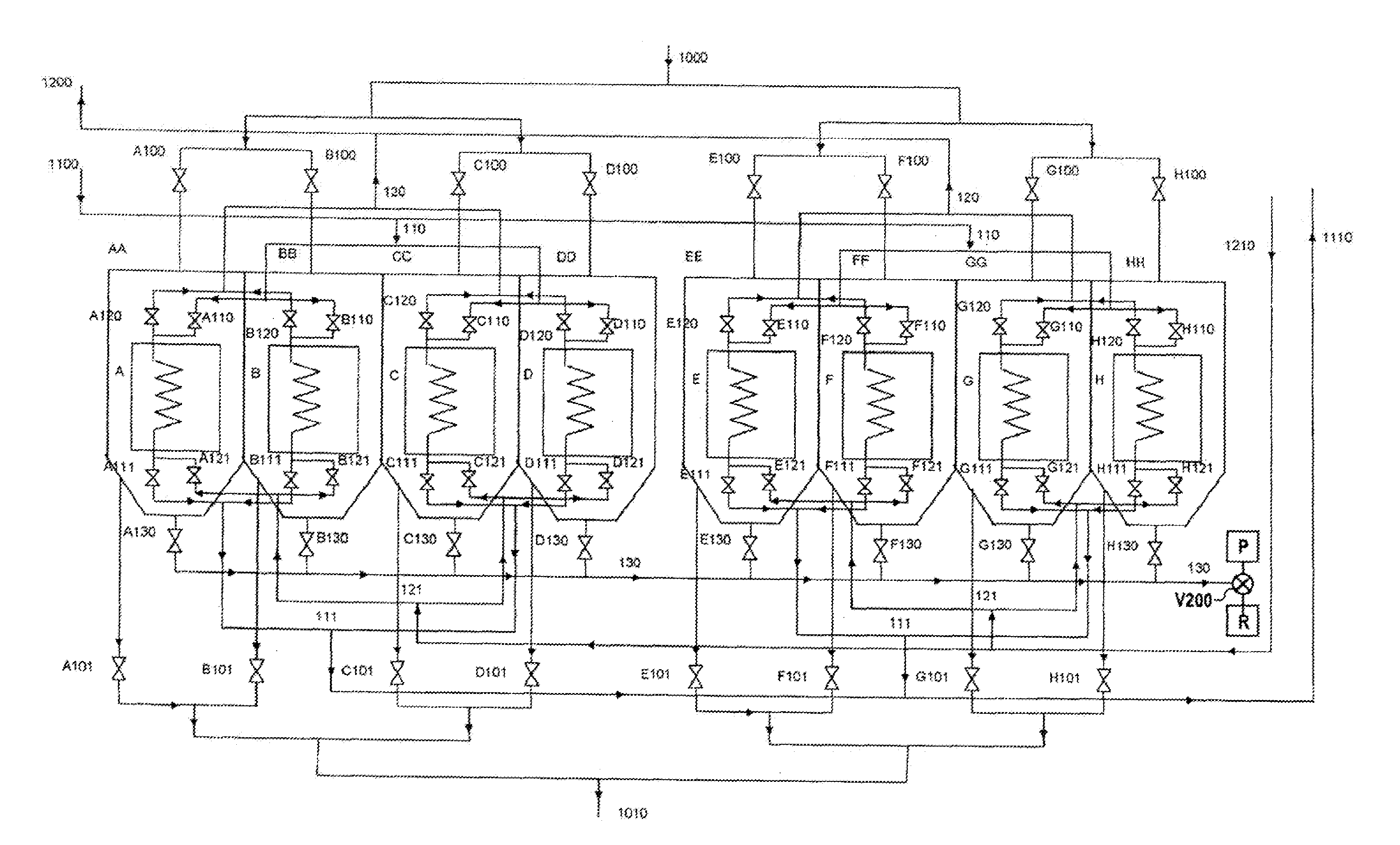

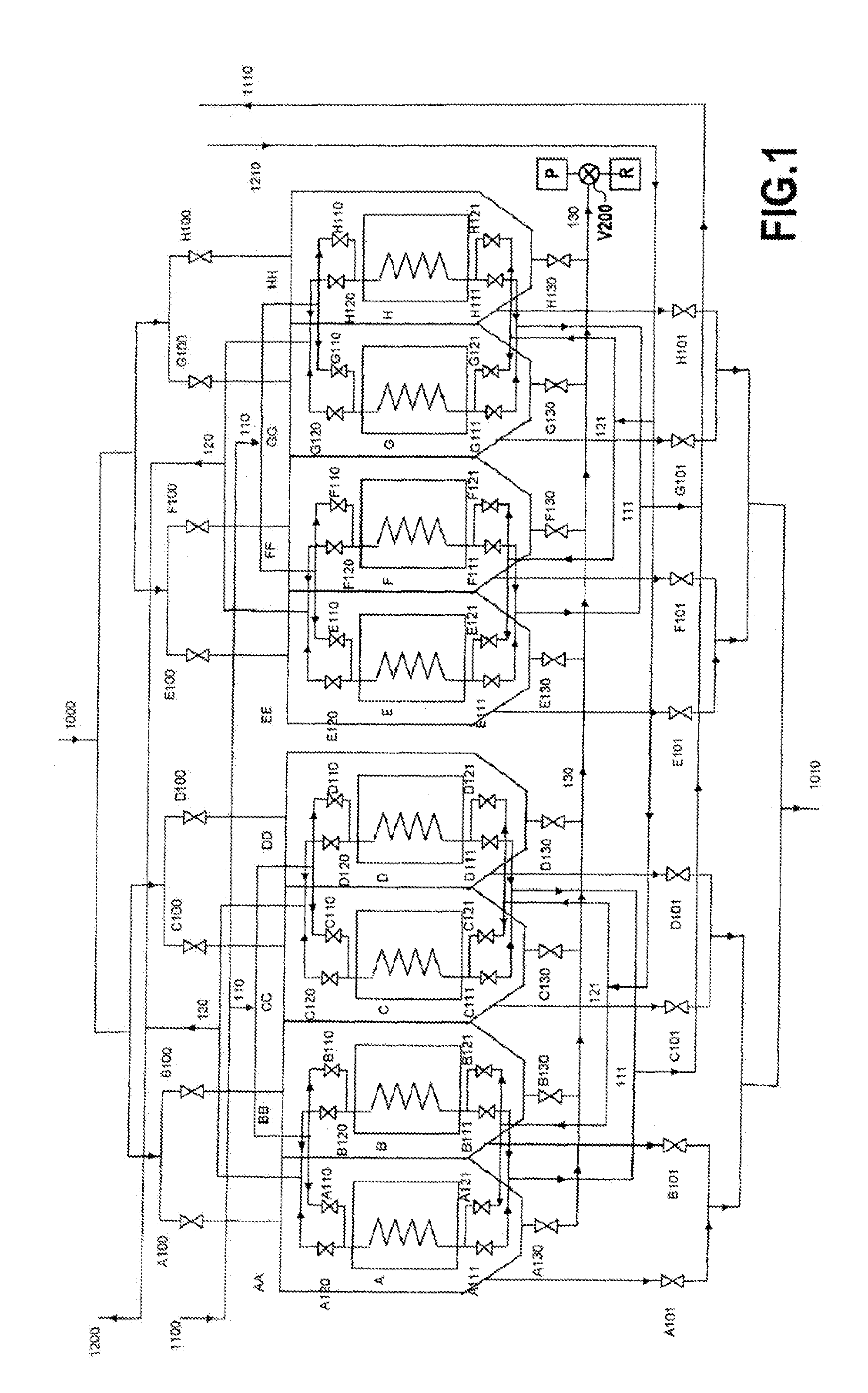

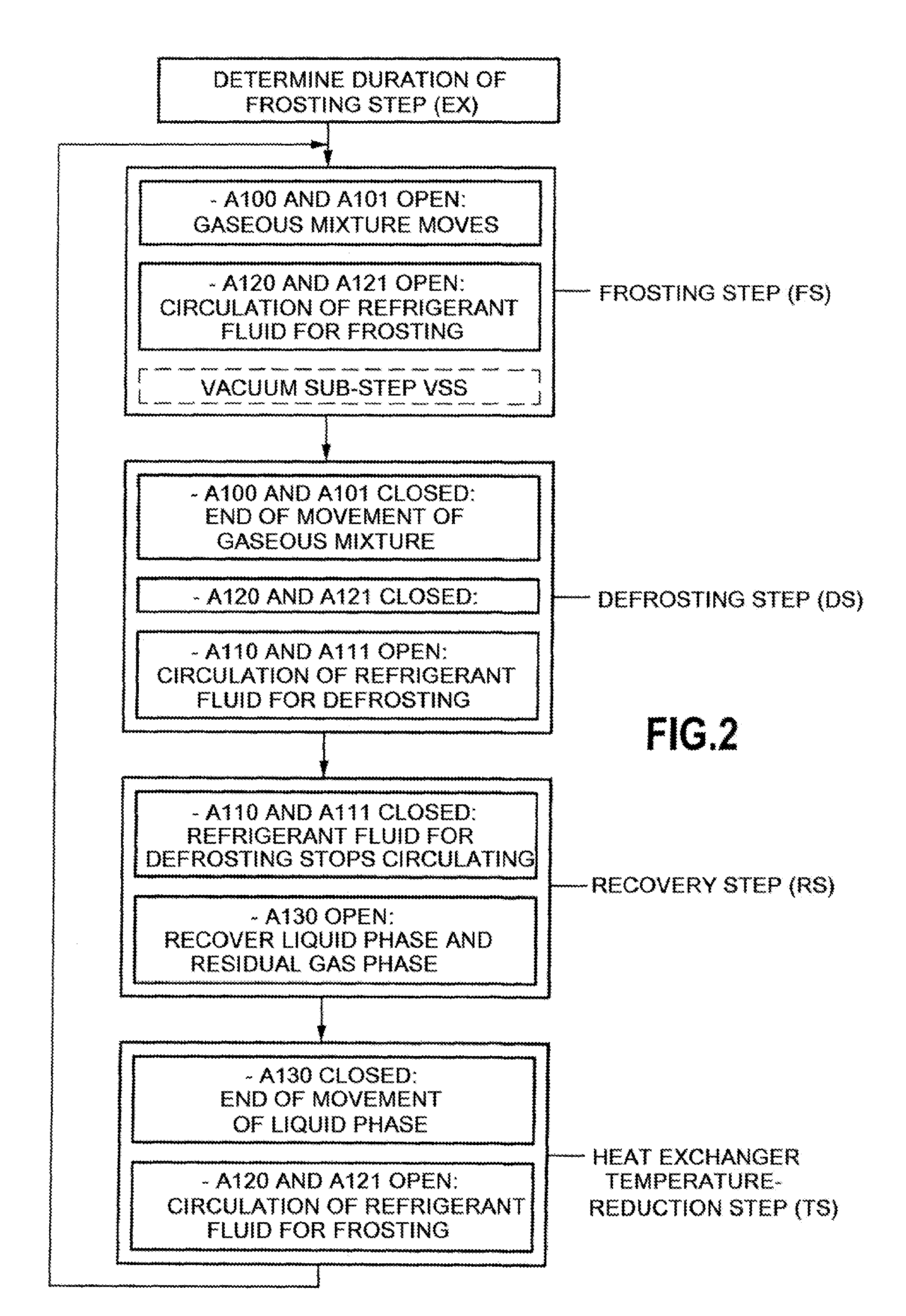

[0134]The present invention provides a system for extracting a substance present in a mixture of process gas or fumes, by bringing about anti-sublimation of that substance on the solid surface of a plurality of freezing heat-exchangers.

[0135]To this end, anti-sublimation of the substance to be extracted is carried out at a temperature and at a pressure lower than that defined by the triple point of the substance under consideration.

[0136]The extraction system of the invention comprises 2N heat-exchangers, N being an integer greater than or equal to three.

[0137]FIG. 1 represents an example of an extraction system of the invention. In this example, the extraction system comprises eight distinct heat-exchangers, such that N is equal to 4.

[0138]The eight heat-exchangers have been shown in FIG. 1 (denoted A, B, C, D, E, F, G, and H).

[0139]The extraction system of FIG. 1 also comprises eight chambers AA, BB, CC, DD, EE, FF, GG, and HH in which the respective freezing heat-exchangers A, B,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Pressure drop | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com